Orbital Stretch Wrapper Manufacturer

The professional manufacturer providing different orbital stretch wrapping machines, horizontal stretch wrapper for horizontal packaging.

About Our Machine

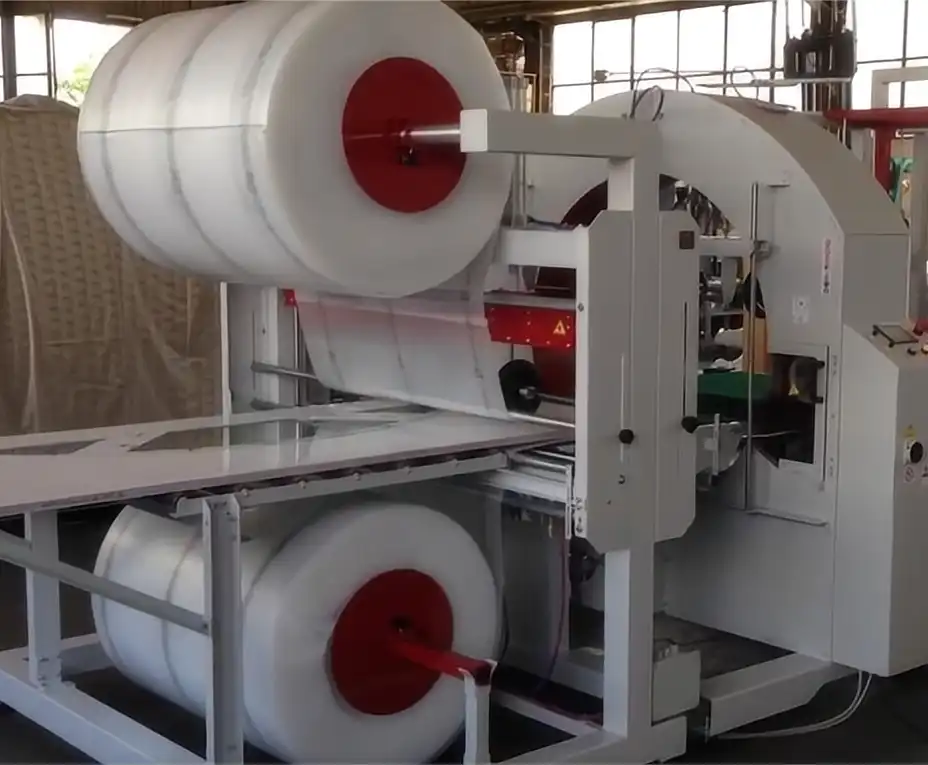

Orbital stretch wrap machine – the solution to streamline your packing process

We are processional packaging machine manufacturer with over 15 years of experience. Our horizontal wrapping machine has the advantage of having a very wide range of products potentially susceptible of being packed with stretch film, in addition to a low cost of the applied material.

Our orbital stretch wrap machine is an industrial packaging equipment that can be applied to large products, furniture of all sizes, kit furniture, doors, windows, stacked plates, textiles, polystyrene, profiles, moldings, blinds, tubes …

20+

Years In Business

1.5k

Happy Clients

2.5k

Projects Completed

150+

Trained Staff

Our Products

Processional Packaging Machine Manufacturer

Why Choose Us

Six Reasons For You Choosing Our Machine

We Are Manufacturer Who Cares, And it Shows.

OVER 540 “5 STARS” REVIEWS AND CLIMBING