Aluminum packaging line from Chinese manufacturer-----Fhope packaging machinery co.,ltd

- set of No.4 Hydraulic lifters

These are positioned under the skip unloading positions and are designed to automatically maintain the height of the top layer of profiles being lifted out of or into a skip.Standard lifing capacity is 400 kg per unit.Includes photocells ,electrical part and all hydraulics,

Max.lifting stroke : 800 mm

Lifing time : approximately 40 secs

- Set of infeed conveyors to protective machine

Motorized roller conveyor for loading the profiles into the adhesive application machine.Includes 3 sets of vertical rolller for centering the profiles as they are loaded into the machine .

Roller conveyor working length : 9000 mm

Working height : 1000 mm

Motor power : 0.37kw

Roller covering :non marking PVC

Maximum loading speed : 60 m/min

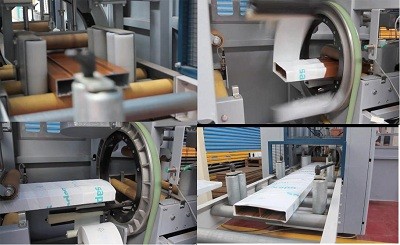

- Adhesive film machine moodfi “884”(continuous operation with automatic cut )

Newly designed machine designed to attach an adhesive film to top and bottom faces of the profiles smoothly and without creating blisters in the film itself .The machine includes a blade unit for cutting the adhesive tape between one profile and the next profile ,without stopping the machine for each cutting cycle .The newly designed blade unit ensures a clean cut with the elimination of any overhanging tape.

Time required to replace a roll of adhesive film : approximately 45 seconds

Time required to change the type of profile :less than 2 minutes

Maximum operating speed : 60 m/minute(7*8 m long profiles per minute)

Roll dimensions :

Internal diameter 75 mm

Max external diameter :200 mm

Max width :300 mm

Max profile with :300mm

Max profile height :200 mm

Included in the supply : kit for applying adhesive film to both side face of the profiles when necessary (max height 200 mm)

- Outfeed belt conveyor

This belt conveyor is designed to auotomatically transfer profiles out of the adhesive film application machine.

Working width :400 mm

Working length : 9700 mm

Working height : 1000mm

Working speed : 60 m /minute

Belt material : hard wearing green PVC

5 .set of 4 cross transfer belts

These belt conveyors are designed to automatically transfer profiles across from the adhesive film line to the wrapping machine line.

Number of belts : 4

Working width : 80 mm

Working length :3200 mm

Working height : 1000 mm

Working speed : 10 m /min

Belt material : hard wearing green PVC

6F.R.sub-bundle roller conveyor

Manufactured in a welded steel frame ,this conveyor comprises a combination of motorized as welll as idle high density rollers supported by bearings ,pneumatic centring systems that guide the bundles with a self –adjusting closing action according to the bundle dimensions .Individual or sub-bundles of the profiles are loaded either automatically (single profiles)or manually when sub-bundles need to be made up by the operators)onto the roller conveyor by mechanically operated lift over arms (4) which are lifted over by a cam device on a connecting rod .roller system driven by means of an electronic driver ,pinch-roll feeding system controlled electronically which prevents contact between the rear of one bundle and the front of the next one .The system is fitted with a :pincer system “for centring the profiles while they are being lifted across onto the roller conveyor .

Machine size : 500 mm

Width (standard ) :9200 mm

Number of cam –operated lift over arms : 4

Working height : 1000 mm

Max sub-bundle feed speed (standard): 40 m/min

Drive system : motor gear with inverter

Motor power : 0.37 kw

7.large spiral wrapping machine model “F.A.2”

Aluminum packaging line and Machine designed with a compact steel frame .Replacement of wrapping material is carried out quickly and easily (under one minute )using bayonet type quick change holders for rolls of wrapping materials .profiles are drawn through the machine by a series of rollers which open and close automatically ,allowing bundles with different dimensions to pass through automatically without stopping the machine ,The wrapping device is composed of a rotor which rotatess and holds the roll of wrapping film which is supported by a mandrel with specially designed dutch designed to maintain the tension constant until the roll is finished .Thees rolls are easily and quickly replacec in less than one minute .The speed is regulated by means of an electronic inverter controlled through a potentionmeter situated on the main control panel .An automatic device senses when the roll has run out or should the wrapping material tear ,bringing the machine to a complete stop and warning the operator .Machine designed to operate in “stop and go “ mode with a blade cutting the wrapping material automatically at the end of the each wrapping cycle .

Speed regulation : by inverter

Machine size (standard )

Width 1500 mm

Height 1500 mm

Length 1600mm

Maximum speed 40 m per minute in “continous “mode (standard machine )

Maximum bundle sizes : rectangular 300m m wide * 200 mm high or 150*150mm square

Minimum bundle sizes : rectangular 40mm wide *20mm high or 40*40 mm square

Wrapping material used :

Nr.2 rolls of nylon strech film or paper :

Outer diameter :maximum 350 mm

Inner diameter : maximum 50 or 76 mm(to be confirmed)

Width 100/120 mm

8.taping machine model “N.M.P.3”(continuous operation )

This machine tapes the front and back of the profiles as they are moving through it and dose not need to stop ,taping “on the fly “.It tapes several spirals (binding coils) to the front and back end of each bundles tjo prevent the wrapping material from unravelling .It is programmed to tape the profiles according to the speed of the wrapping machine lying before it ,Used mainly when wrapping with paper or nylon which is particularly prone to tearing and wnravelling .When wrapping with strech film ,the machine can be paused and switched to idle mode .

Taping material :no.2 adhesive tape rolls

Innner diameter : 75 mm

External diameter : 120mm

Machine dimensions :

Width :1100mm approx

Length : 1800 mm approx

Height : 1400 mm approx

Machine characteristics :

Motor power total 1 kw

Nr.5 pneumatic devices

Max taping speed : 40 m per minute (standard )

Recommend dimensions of the reels of adhesive tape :

No.2 PVC reels:

Internal diameter 75 mm

External diameter : 120 mm

Width : 20 mm

- outfeed roller conveyor with automatic bundle stacker modle

This machine is fitted with a pinch-roller device which is acceleratd by an inverter.It carries out the detachment of the finished bundle and then stops in the right position,aligned for the formation of the bundle layers.Idle roller length 8000mm with pneumatic guides.Automatic device with lifters for the formation of the bundles.A special pneumatically operated device automatically interlaces a nylon cord between each layer of profile bundles while it is in production to prevent these from sliding over when moved .This machine is continuously fed by the bundles coming form the wrapping machine ; it superimposes them layer on the layer producing in this way a bundle of the size chosed by the operated on the main control panel .

Characteristics ( for standard machine ):

Wrapped bundles from 3000 mm up to 7000mm in length

Maximum speed : 40 m/minute

Finished bundle size : max width 600 m (800 mm on request )

Max height 600 mm (800 mm is on request )

Bundle –maximum weight :2000 kg

Machine size (standard ):

Width 2400 mm

Length 8000 mm

Height 1300 mm

Weight 1300 kgs

10.cross transfer chain conveyors

These chain conveyors are designed to cross transfer the stacked bundles onto the next machine after the automatic bundle stacker.

Number of the chains : 5

Maximum bundle length : 7000 mm

Working length: 2500 mm

Working height : 300 mm

Working speed : 10 m/ min

Chain material: steel with vulcanized rubber caps

11.Second exit roller conveyor

When the profiles /sub-bundles need to be stacked and packed manually ,the second exit is uesd to transfer the profiles to the manual packing line , the machine includes a pneumatically operated pantograph used to push the profiles across onto the accumulation belts.\

Working length : 10000mm

Working height : 1000mm

Roller material :PVC

Working speed : 40 m/ min

- belt conveyors for profiles cross transfer and accumunition

These conveyors are used to transfwer the profiles / sub-bundles across to the manual packing line .They are fitted with sensors at the end of the belts to prevent the profiles from falling off .

Number of the conveyors : 4

Working length : 1100mm

Working height : 1000mm

Belt material : white nylon (unichain)

Working speed : 10 m/ min

- set of 5 loading chain conveyors for bundle formation

These conveyors are used by the operators to form the bundles and transfer them across onto the main chain conveyors .

Number of the conveyors : 5

Working length : 1200mm

Working height : 500mm

Chain material : steel

Working speed : 10 m/ min

- NR.2 sections loading chain conveyors for the bundles

These conveyors are used to transfer the bundles to the strapping line .

Number of the conveyors : 2

Working length : total 18000mm (2*9000mm)

Working height : 500mm

Working width : 1000mm

Chain material : steel

Working speed : 10 m/ min

- set of loading /unloading chain conveyors for bundles

These conveyors are used to either load or unload the bundles onto the main chain conveyors leading to the strapping line .

Number of the conveyors : 5

Working length : total 2000m

Working height : 500mm

Chain material : steel

Working speed : 10 m/ min

- bundle strapping with wood blocking device

This machine is designed to strap the completed bundles with the wood blocks ( upper ,lower and side wood block ) before the shipping .The strapper itself is equipped with a wood blocking device for clamping the upper ,lower and side wood blocks during the strapping operation .

Drive motor : TFC240/415V ,50 HZ, 0.75KW

Strapping tension : 0- 800 kg (PET straps )

Strap speed : 2.5m/sec

Strap width : from 12mm – 19 mm

Strap thickness : 0.6-1.3 mm

Noise : max 80 .Dba

Head dimensions : W292*L 736*H 305

17.intermediate chain conveyor

This conveyor connects the bundles strapper to the main bundle wrapper .

Working length : 4800m

Working height : 500mm

Working width : 1000mm

Chain material : steel

Working speed : 10 m/ min

- master bundle wrapper

Sturdy machine which ensures the rapid and uniform bundle wrapping .The master packs fo profiles are fed into the machine by the intermediate chain conveyor .The bundles is wrapped by means of a single roll of polythene mounted onto a mandrel which rotates on a rotor and guide by special clutches to control the wrapping tension .The rolls of wrapping material can be replaced quickly and easily .The machine is fitted with an electric device which controls if the material has run out or has torn and automatically stops the machine ,The wrapping cycle is completely automatic.A specially designed clamp is used to hold the first part of the strech film for a consecutive wrapping cycle meaning that the re-starting of the machine for each new bundle to be wrapped is completely automatic.The machine can be proframmed to wrap the whole bundel or partially ( for example : front ,middle and end ) as required .

Speed 10 meter per minute in continuous mode (standard)

Speed regulation by inverter

Dimensions of the bundle(standard)

Width : 200 – 800 mm

Height : 100- 600 mm

Length min. 2500 mm

Dimensions of the suggested roll or wrapping material ( standard )

Single nylon roll :

Maximum : outer diameter 230 mm

Inner diameter : 76 mm

Width : 250 m m

- Final exit chain conveyor for stapped bundles

Working length : 7500m

Working height : 500mm

Chain material : steel

Working speed : 10 m/ min

- set of 5 conveyors for bundles accumuiation

Working length : 3600m

Working height : 500mm

Working width : 1000mm

Chain material : steel

Maximum load : 12000kgs

Working speed : 10 m/ min

: 250 m m

76 mm

terial ( standard )

ndard)

ially ( for example : front ,middle and end ) as required .