Slitting Steel Coil Packaging Line: A Revolution in Efficiency and Safety

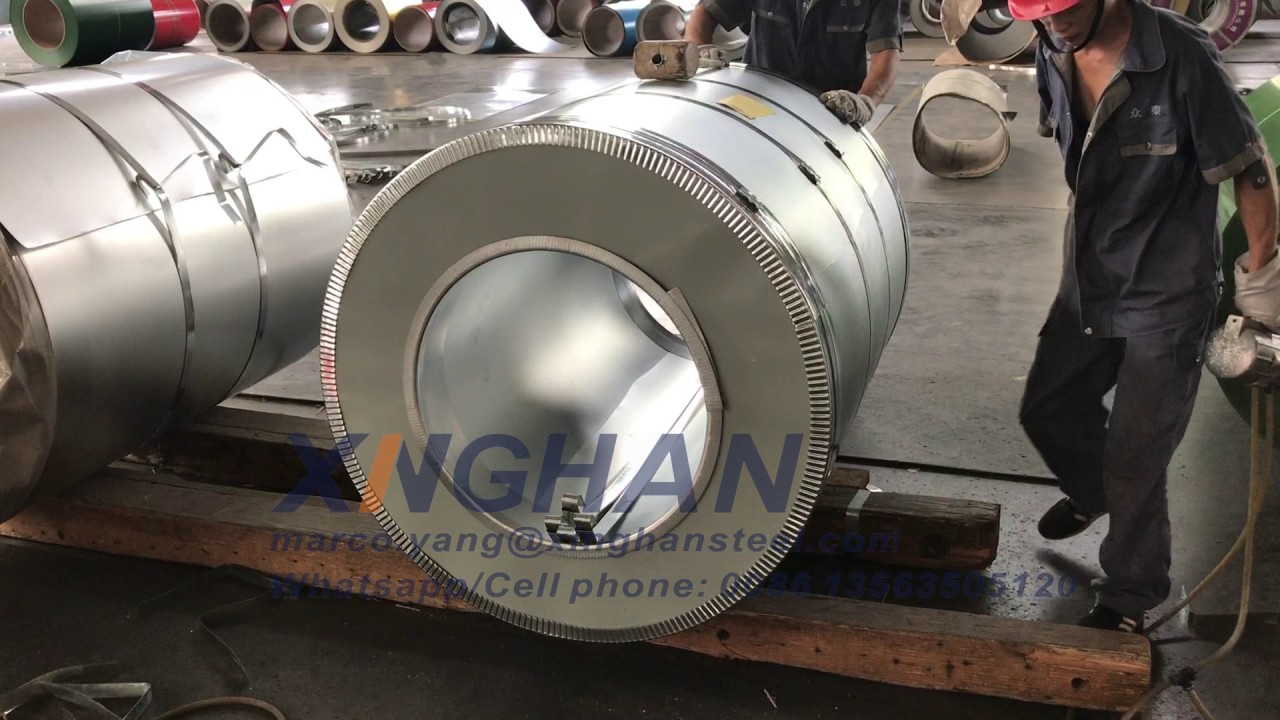

Steel coils are a vital component in many industries, from automotive manufacturing to construction. However, the process of packaging these coils for transportation and storage can be time-consuming and labor-intensive. That is until now. The introduction of the full-auto slitting coil packaging line has revolutionized the way steel coils are handled, making the entire process faster, safer, and more efficient.

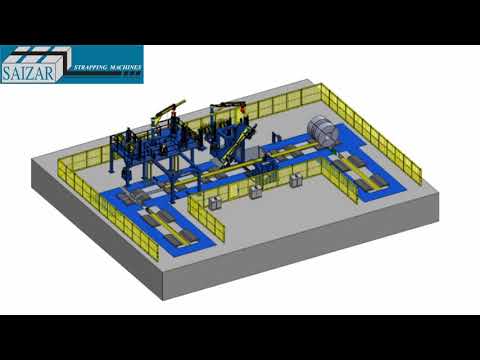

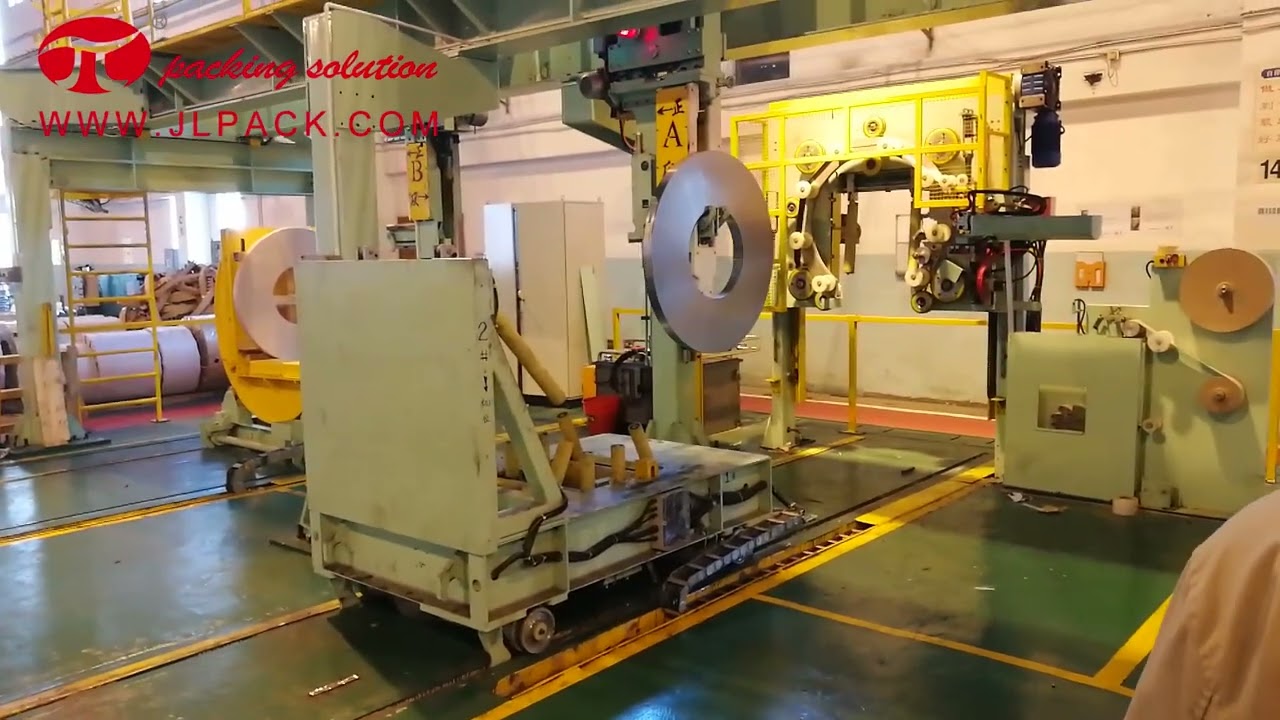

The coil packing line combines a range of functions including strapping and wrapping, eliminating the need for manual labor and reducing the risk of injuries. This state-of-the-art technology has garnered attention from various stakeholders - from technical engineers to customers and even industry magazines. Let's explore the benefits and features of this groundbreaking innovation.

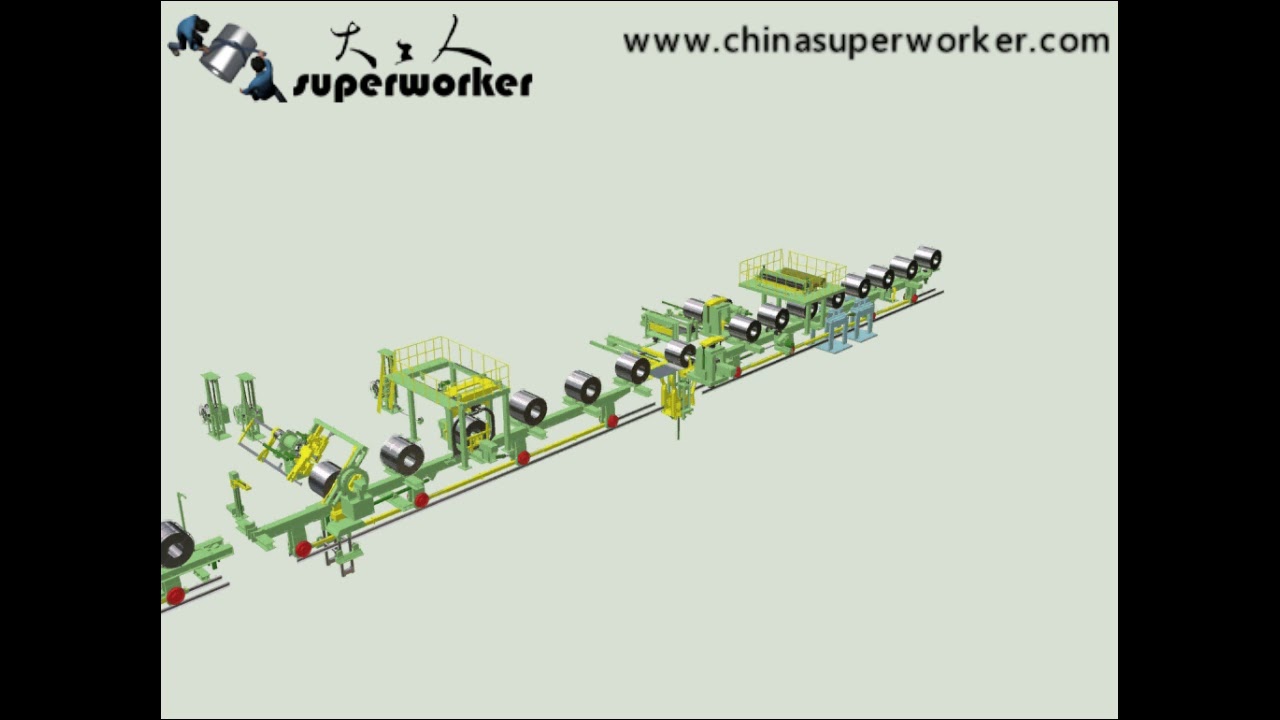

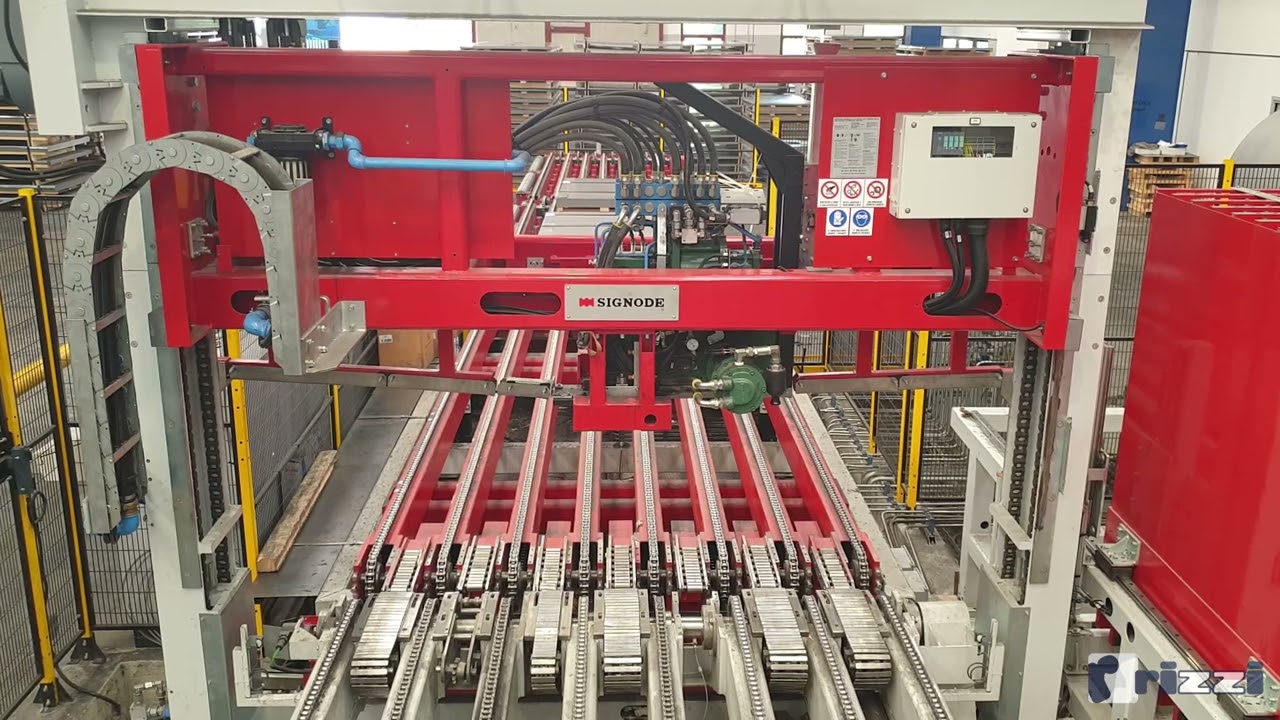

The full-auto slitting coil packaging line is designed to streamline the packaging process. It begins with the automatic feeding of the steel coils into the machine, where they are accurately positioned for the subsequent steps. The line then moves onto the strapping function, ensuring that the coils are securely bound together. This not only prevents coil damage during transportation but also minimizes the risk of accidents due to loose coils.

Next, the line seamlessly transitions to the wrapping function. The coils are enveloped in a protective layer of stretch film, shielding them from dust, moisture, and other external factors. This packaging not only safeguards the coils but also facilitates efficient handling and storage. The entire process is automated, reducing the need for manual intervention and increasing productivity.

From a technical engineer's perspective, the coil packing line is a marvel of engineering. Its precise positioning system ensures accurate alignment of the coils, preventing any potential mishaps during strapping and wrapping. The automation of the process guarantees consistency and reliability, minimizing the chances of human error. This technology has truly elevated the efficiency and safety standards of coil packaging.

For customers, the full-auto slitting coil packaging line offers numerous advantages. Firstly, it significantly reduces the time required for packaging, resulting in faster turnaround times and improved delivery schedules. Additionally, the automated process ensures consistent packaging quality, eliminating variations caused by human factors. This not only enhances customer satisfaction but also reduces the likelihood of damaged coils reaching their destination.

Industry magazines have also taken note of this groundbreaking technology. Many have featured articles highlighting the benefits and impact of the coil packing line on the steel industry. These publications often focus on the transformative nature of the technology, its potential to improve overall operational efficiency, and the positive impact on the bottom line.

In conclusion, the full-auto slitting coil packaging line has revolutionized the way steel coils are handled, packaged, and transported. Its automated functions, including strapping and wrapping, have eliminated the need for manual labor and significantly reduced the risk of accidents. Technical engineers, customers, and industry magazines have all recognized the immense value this technology brings to the steel industry.

With its precise positioning system, automation, and consistent packaging quality, the coil packing line ensures efficiency, safety, and customer satisfaction. This innovation has truly transformed the packaging process, allowing for faster turnaround times, improved delivery schedules, and reduced coil damage. As the steel industry continues to evolve, the coil packing line stands as a testament to the power of technology in revolutionizing traditional practices.

coil packing line

"Efficient and Automated Coil Packaging Solutions: Enhancing Productivity with Full-Auto Slitting Coil Packing Line"