Coil Packing Line: Revolutionizing the Steel Tube Packaging Process

The steel industry has always been at the forefront of innovation, constantly seeking ways to improve efficiency and productivity. One significant advancement that has taken the industry by storm is the coil packing line. This state-of-the-art equipment has revolutionized the steel tube packaging process, offering numerous benefits to manufacturers. In this article, we will delve into the intricacies of the coil packing line and explore how it has transformed the steel industry.

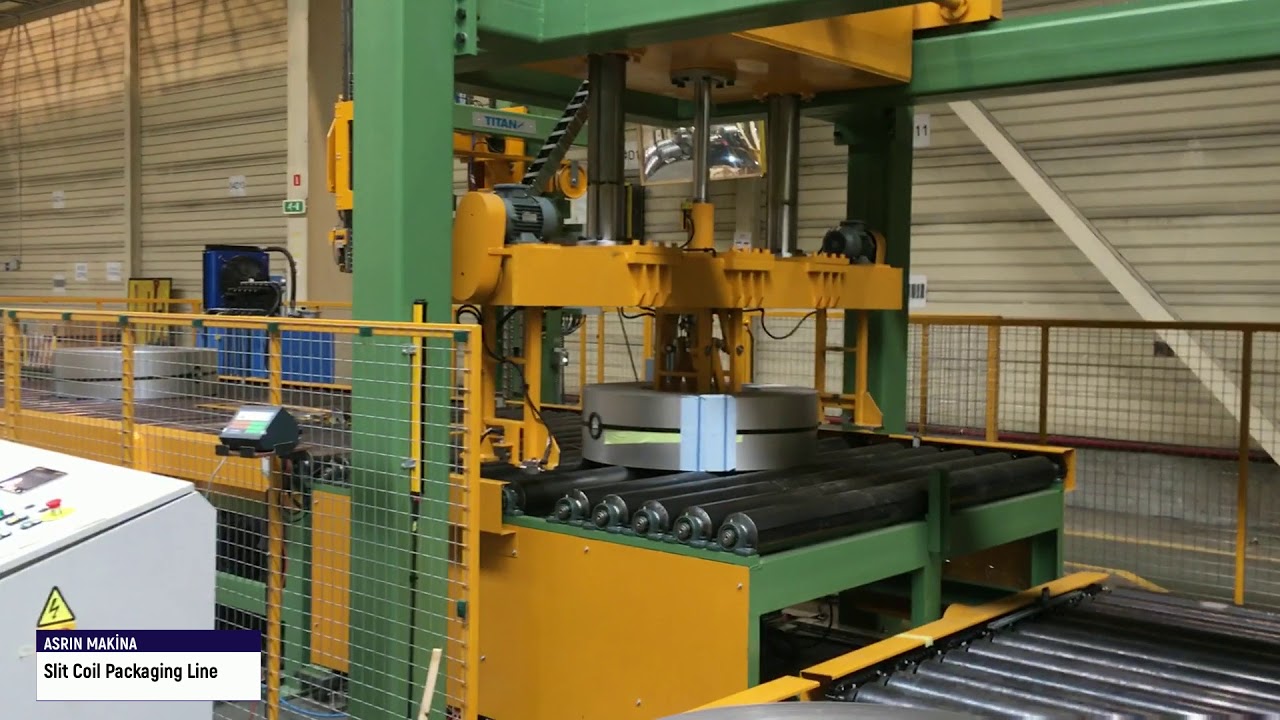

The coil packing line is a marvel of engineering, designed to streamline the packaging process for steel tubes. It consists of a series of automated machines that work seamlessly together to ensure efficient and precise coil packaging. From coil strapping to wrapping, these machines eliminate the need for manual labor, reducing the risk of human error and enhancing overall productivity.

One of the key components of the coil packing line is the steel tube coil horizontal packing line. This machine plays a crucial role in the packaging process, ensuring that the coils are securely packed and protected during transportation. The steel tube coil horizontal packing line utilizes advanced technology to wrap the coils tightly, preventing any damage or deformation. This is particularly important when it comes to delicate steel tubes that require extra care during packaging.

The coil packing line offers a myriad of advantages for manufacturers. Firstly, it significantly reduces labor costs. With the automation of the packaging process, manufacturers can cut down on the number of workers required, thereby reducing expenses. Additionally, the coil packing line improves overall efficiency by increasing the speed of packaging. What used to take hours can now be done in a matter of minutes, allowing manufacturers to meet tight deadlines and maximize output.

Moreover, the coil packing line enhances the quality of packaging. By eliminating human error, it ensures that the coils are wrapped perfectly every time. This not only enhances the aesthetic appeal of the packaged products but also provides superior protection during transportation. Manufacturers can rest assured that their steel tubes will arrive at their destination in pristine condition, minimizing the risk of costly damages or returns.

Another noteworthy benefit of the coil packing line is its versatility. It is designed to accommodate a wide range of coil sizes and shapes, making it suitable for various steel tube specifications. Whether it’s round, square, or rectangular tubes, the coil packing line can handle them all. This versatility makes it a valuable asset for manufacturers who produce a diverse range of steel tubes.

In addition to its many advantages, the coil packing line also contributes to a more sustainable manufacturing process. By automating the packaging process, it reduces the consumption of packaging materials, such as plastic wrap or straps. This not only reduces waste but also lowers the carbon footprint of the steel industry. As sustainability becomes an increasingly important consideration for manufacturers, the coil packing line offers a viable solution to minimize environmental impact.

The coil packing line has undoubtedly transformed the steel tube packaging process, offering unparalleled efficiency, precision, and versatility. Its impact on the industry is undeniable, revolutionizing the way manufacturers package their steel tubes. As automation continues to shape the future of manufacturing, it is safe to say that the coil packing line will remain at the forefront of innovation, driving the steel industry towards a more efficient and sustainable future.

coil packing line

“Efficient Horizontal Packing Line for Steel Tube Coils: Streamline Your Coil Packaging Process”