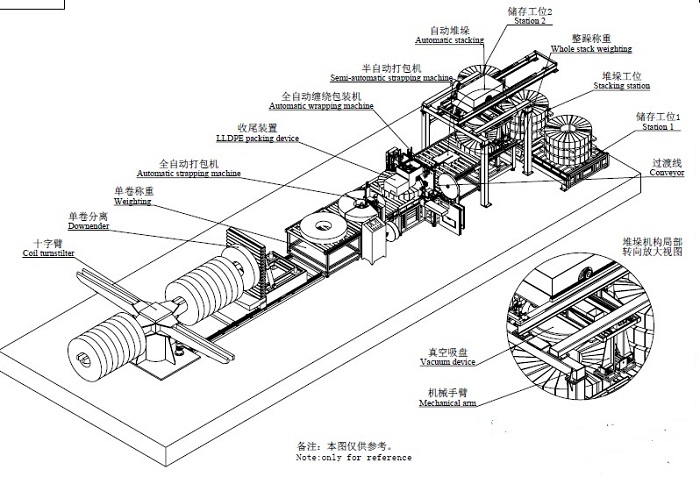

Full-automatic steel coil stacking packaging line you described is a highly automated system that is designed to efficiently package steel coils for storage or transportation. The line is able to connect to a slitting line and pick up coils from a turnstile arm, and then uses automatic strapping machines to secure the coils with straps through the ID coil tail. The packaged coils are then stacked onto a skid for storage or shipment. This type of packaging line can greatly reduce the labor and time required to package steel coils, allowing for higher efficiency and productivity. It is likely that the line also includes various quality control and inspection systems to ensure that the steel coils are properly packaged and secure.

The packing and handling system for the slitting coil you described is designed to improve efficiency, protect the surface of the products, and reduce maintenance time and cost. Some specific ways in which the system may achieve these goals include:

a. Increasing the coil handling and packing speed: By automating the process of feeding, wrapping, strapping, and stacking the steel coils, the system can greatly increase the speed at which the coils are packaged and prepared for storage or transportation.

b. Protecting the product surface and reducing damage: By using protective wrapping material and securing the coils with straps, the system can help prevent damage to the surface of the steel coils during handling and transportation.

c. Saving man power: By automating much of the packaging process, the system can significantly reduce the labor required to package the steel coils, freeing up workers to focus on other tasks.

d. Reducing maintenance time and cost: By using high-quality, durable equipment and minimizing the handling of the steel coils, the system can reduce the need for maintenance and prolong the lifespan of the equipment, ultimately reducing maintenance time and cost.

Automatic packing and handling system you described is designed to not only protect the steel coils from damage, but also to provide dust and moisture protection for non-ferrous coils by wrapping them in plastic stretch film. Additionally, the system is user friendly and includes tracking, weighing, and labeling capabilities to aid in shop and stock control. These features can help ensure that the steel coils are properly packaged and protected during storage and transportation, and can also provide valuable information for inventory management and production planning.

Contact:

www.fhopepack.com