High-Speed Full Automatic Cable Coiler: Revolutionizing Coil Packing Lines

In today's fast-paced world, efficiency is the name of the game. Every industry is constantly on the lookout for innovative solutions that can streamline their processes and increase productivity. The cable manufacturing industry is no exception. With the increasing demand for cables in various sectors, it has become crucial to find a reliable and efficient way to coil and pack them. That's where the Domeks Speedmatik-240 comes in - a high-speed full automatic cable coiler that is revolutionizing coil packing lines.

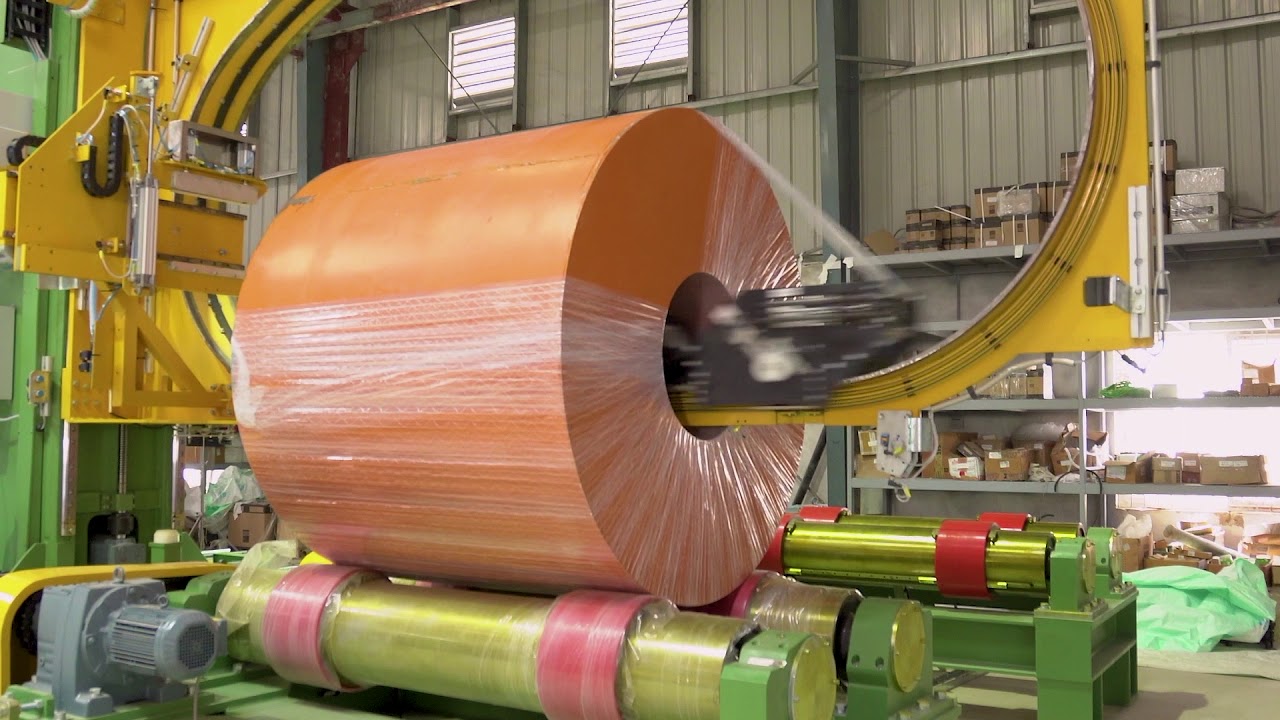

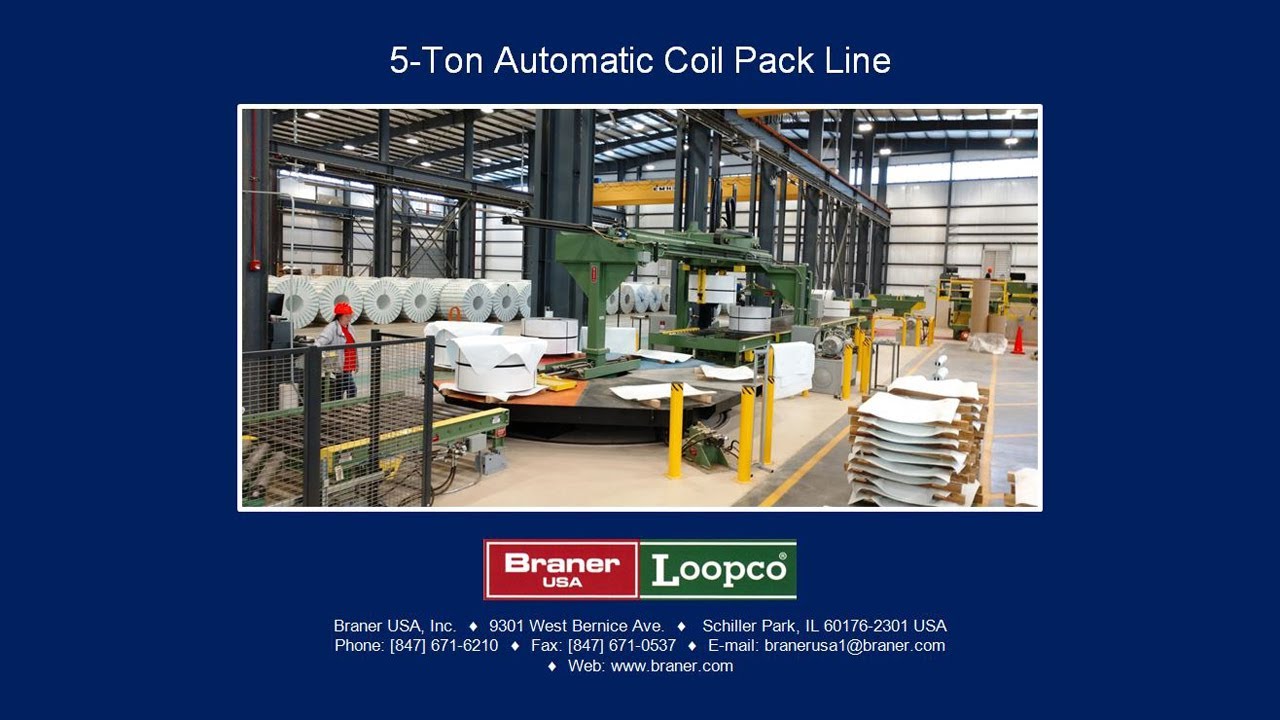

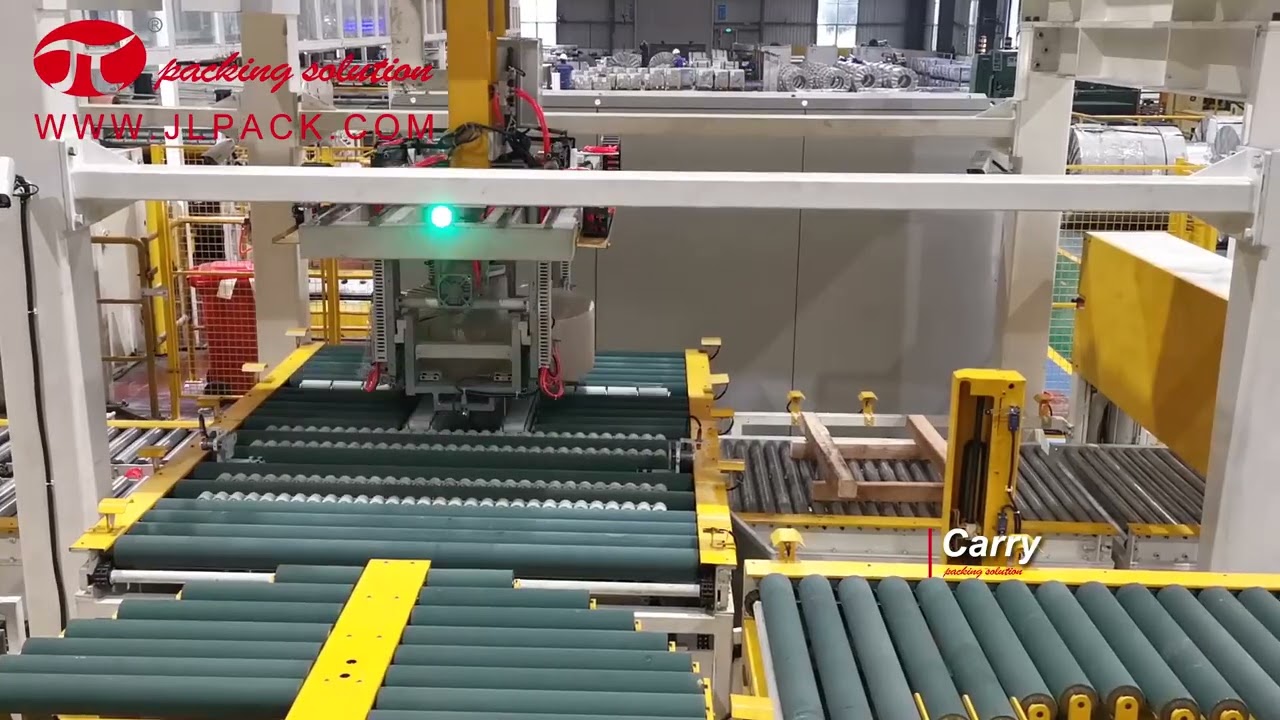

Coil packing lines are an integral part of the cable manufacturing process. They ensure that cables are neatly coiled and securely packed for transportation and storage. However, traditional coiling methods can be time-consuming and labor-intensive. Manual coiling requires significant human effort, and the resulting coils may not always be consistent in size and shape. This can lead to difficulties in transportation and handling.

The Domeks Speedmatik-240 is changing the game by offering a fully automated solution to cable coiling. This state-of-the-art machine utilizes advanced technology to coil cables at high speeds with unparalleled precision. Equipped with a cutting-edge control system, it can adjust the coiling parameters according to the specific requirements of each cable. This ensures uniformity in coil size and shape, eliminating any potential complications during transportation and storage.

One of the key features of the Domeks Speedmatik-240 is its high speed. With a production rate of up to 240 meters per minute, it can coil cables at an impressive pace. This significantly reduces production time and increases overall efficiency. The machine's automatic cable feeding system further enhances its speed and productivity, allowing for continuous operation without the need for manual intervention.

Another notable feature of the Domeks Speedmatik-240 is its versatility. It can easily accommodate cables of various dimensions and types, making it suitable for a wide range of applications. Whether it's power cables, communication cables, or data cables, this machine can handle them all. Its adaptability makes it a valuable asset for cable manufacturers who deal with different types of cables on a regular basis.

In addition to its speed and versatility, the Domeks Speedmatik-240 prioritizes operator safety. It is equipped with a range of safety features, including emergency stop buttons and protective barriers. The machine also undergoes rigorous testing and quality control procedures to ensure reliability and compliance with industry standards.

The introduction of the Domeks Speedmatik-240 has been met with great enthusiasm by cable manufacturers worldwide. Its advanced capabilities have significantly improved their production processes, allowing them to meet growing market demands more efficiently. By automating the coiling and packing process, this machine has not only reduced labor costs but also minimized the risk of human error, resulting in higher-quality coils.

Furthermore, the Domeks Speedmatik-240 has had a positive impact on the overall supply chain. Its ability to produce consistent and well-packaged coils has led to smoother transportation and handling. This, in turn, has reduced the chances of cable damage during transit, providing customers with a superior product and enhancing their satisfaction.

In conclusion, the Domeks Speedmatik-240 is a game-changer in the cable manufacturing industry. Its high-speed, fully automated capabilities have revolutionized coil packing lines, making them more efficient and reliable. With its advanced technology, versatility, and emphasis on operator safety, this machine has become an invaluable asset for cable manufacturers worldwide. As the demand for cables continues to rise, the Domeks Speedmatik-240 ensures that the industry is well-equipped to meet these evolving needs.

coil packing line

"Optimize Your Coil Packaging Process with Speedmatik-240 - Boost Efficiency and Productivity"