httpsAutomatic steel coil packaging line

://www.fhopepack.com

Product description.

The coil packing line according to customer requirements, tailor-made an appropriate automatic coil packaging line to comply with customer needs.

Functioning process:

Immediately allocation→ automated sealing and cutting→ automatic diminishing → Automated box opening→automatic package package deal →automatic box weighting→automatic Coding→ Automatic collapsable and securing →automatic four part side sealing →automatic”I”type molded strapping → self-steering→ palletizing process → Intelligent pallet packaging →automatic putting on a sword way strapping machine→ automatic horizontal stretch wrapper strapping →automatic top laminating machine →automatic winding on line → completed.

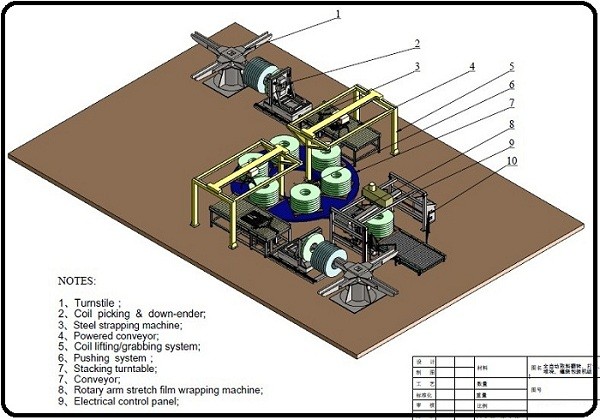

Machine components:

The packing line utilized by the items include: immediately allocation, intelligent securing and decreasing, automatic shrinking, auto container launching machine, automati ccoil packing machine, weighing machine, coding machine, auto collapsable and sealing coil wrapping machine, auto a number of spot benefit sealing machine,”I” formed strapping, palletizing techniques, automated pallet strapping, auto putting on a sword-strapping machines, automatic horizontal strapping machine, automated top rated laminating machine, automatic line winding machine, which mechanically supporting the usage of the production line, and in addition remain-by itself operation.

practical variables:

Procedure: placing goods on conveyor belt personally- break up machine checking- set up organization- moving to L-type closing and decreasing machine- show to therapy agency right after packing- thermostat shrink oven- finish product or service- express system

Entire coil packaging line working pace: 1-2 package/minutes (25 in one deal, 100 outside the house diameter milling tire)

Whole line potential is around: 22KW, 380V/50Hz

Needed staff from the Total line: 1-2 people, minimize the labor intensity and improve manufacturing productivity

The amount level of generation working flooring is easy to customize, generally 600mm, changeable array is 50-100mm.