The Evolution of Coil Packaging Lines: A Technological Revolution in the Manufacturing Industry

Coil packaging lines have undergone a significant transformation in recent years, thanks to advancements in technology. These cutting-edge machines have revolutionized the way coils are packaged and transported, streamlining the manufacturing process and ensuring the utmost efficiency. In this article, we will explore the remarkable features of the coil packing line, and its impact on the industry as a whole.

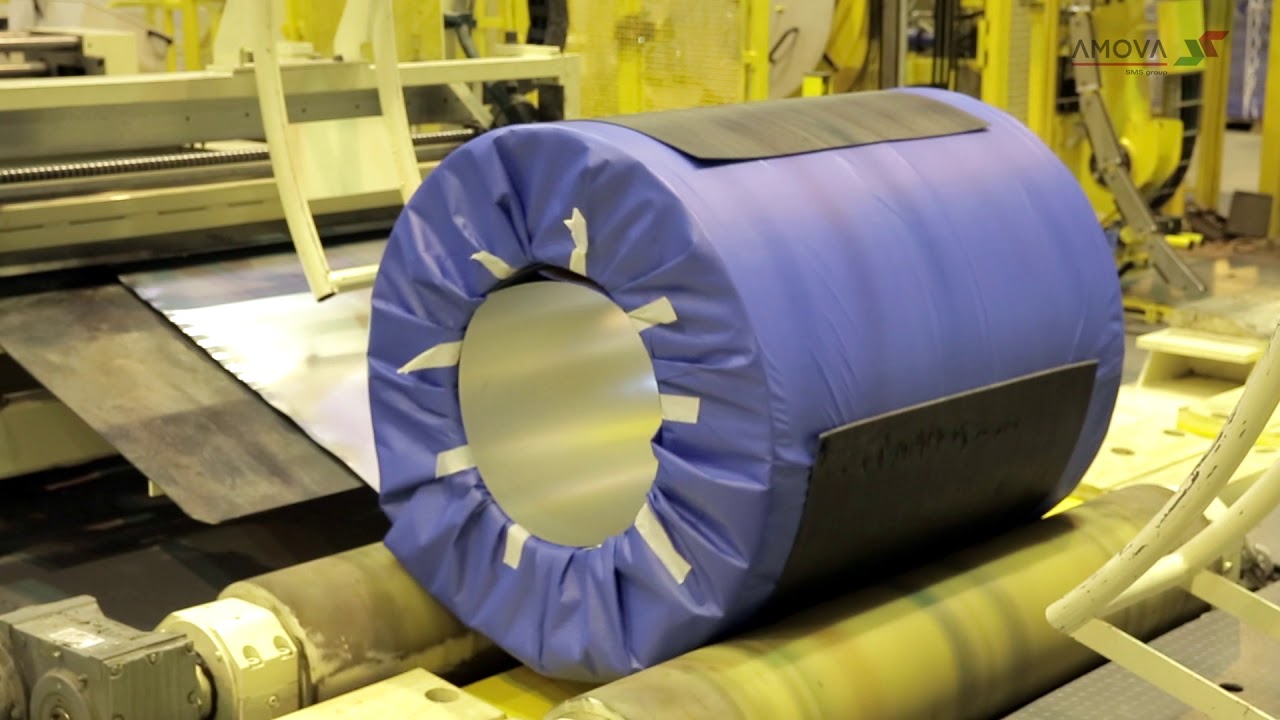

The MMK Magnitogorsk, Russia – coil packaging lines are a testament to the incredible progress made in this field. Equipped with state-of-the-art stretch-film machines and fully automatic paper and sheet wrapping capabilities, these packaging lines have set a new standard for efficiency and precision. The integration of these advanced features has transformed the way coils are packaged, ensuring their safety during transportation and storage.

One of the standout features of these packaging lines is the stretch-film machines. These machines have the ability to wrap the coils tightly, providing excellent protection against moisture, dust, and other external factors. The stretch-film not only acts as a shield but also enhances the stability of the coil, preventing any potential damage during transit. This innovative technology has significantly reduced the need for manual labor, thus increasing productivity and minimizing human error.

In addition to stretch-film machines, the fully automatic paper and sheet wrapping capabilities of these packaging lines have further enhanced their efficiency. The use of paper and sheet wrapping provides an extra layer of protection to the coils, ensuring their integrity throughout the entire packaging process. This automated system eliminates the need for manual intervention, saving valuable time and resources.

The coil packing line is a prime example of how technology has transformed the manufacturing industry. With its fully automated features, it has revolutionized the way coils are packaged, making the process faster, more efficient, and safer. The integration of stretch-film machines and automatic paper and sheet wrapping capabilities has eliminated the need for manual labor, reducing the risk of human error and increasing overall productivity.

The impact of these technological advancements goes beyond just the manufacturing process. The coil packing line has also had a positive effect on the environment. By minimizing the use of packaging materials and reducing waste, these machines contribute to sustainable manufacturing practices. They help companies reduce their carbon footprint while maintaining high levels of productivity and efficiency.

Furthermore, the coil packing line has not only benefited the manufacturers but also the customers. The enhanced packaging ensures that the coils arrive at their destination in pristine condition, minimizing the risk of damage during transportation. This, in turn, leads to increased customer satisfaction and loyalty.

Looking ahead, the future of coil packaging lines seems promising. As technology continues to advance, we can expect even more sophisticated features and capabilities to be integrated into these machines. From improved automation to enhanced safety measures, the possibilities are endless.

In conclusion, the coil packing line represents a technological revolution in the manufacturing industry. With its fully automatic features, it has transformed the way coils are packaged, ensuring maximum efficiency and safety. The integration of stretch-film machines and automatic paper and sheet wrapping capabilities has revolutionized the entire packaging process, reducing the need for manual labor and increasing overall productivity. As we embrace these advancements, we can look forward to a more sustainable and efficient manufacturing industry.

coil packing line

“Efficient Coil Packaging Solutions: Streamlining Production in Magnitogorsk, Russia’s Manufacturing Industry”