Steel Wire Coil Packing Equipment: Streamlining the Packaging Process

Coil packing lines play a crucial role in ensuring efficient and effective packaging of steel wire coils. These lines are equipped with advanced technologies and innovative features that streamline the packaging process, offering numerous benefits to both manufacturers and end-users. In this article, we will delve into the world of coil packing lines and explore how they revolutionize the steel wire coil packaging industry.

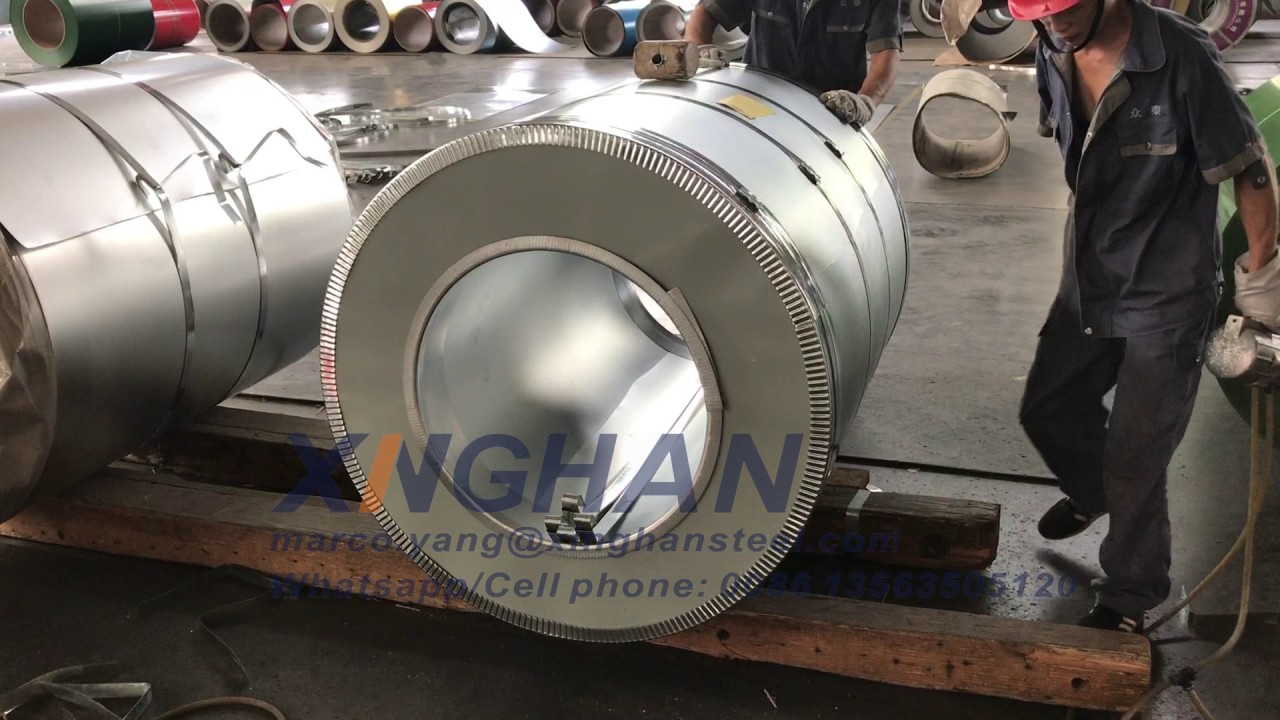

Steel wire coils are widely used in various industries, including construction, automotive, and manufacturing. To protect these coils during storage and transportation, it is essential to package them securely. This is where coil packing lines come into play, providing a comprehensive solution to efficiently pack and protect steel wire coils.

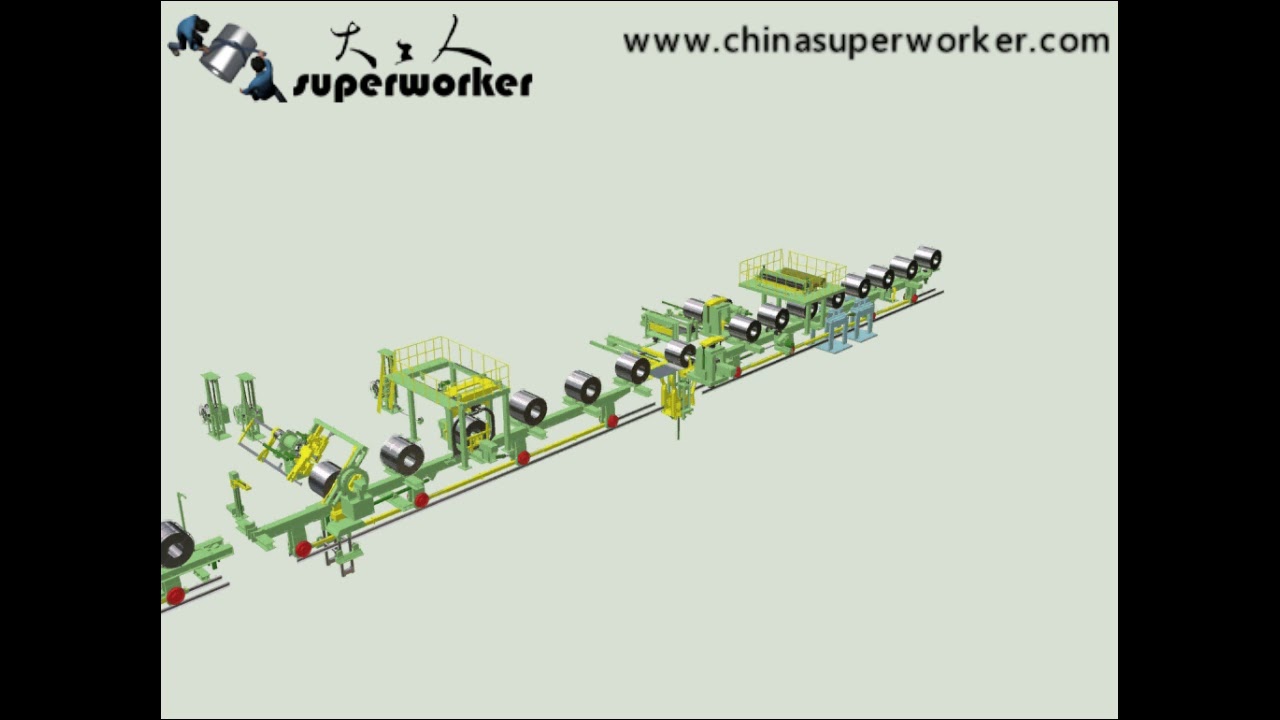

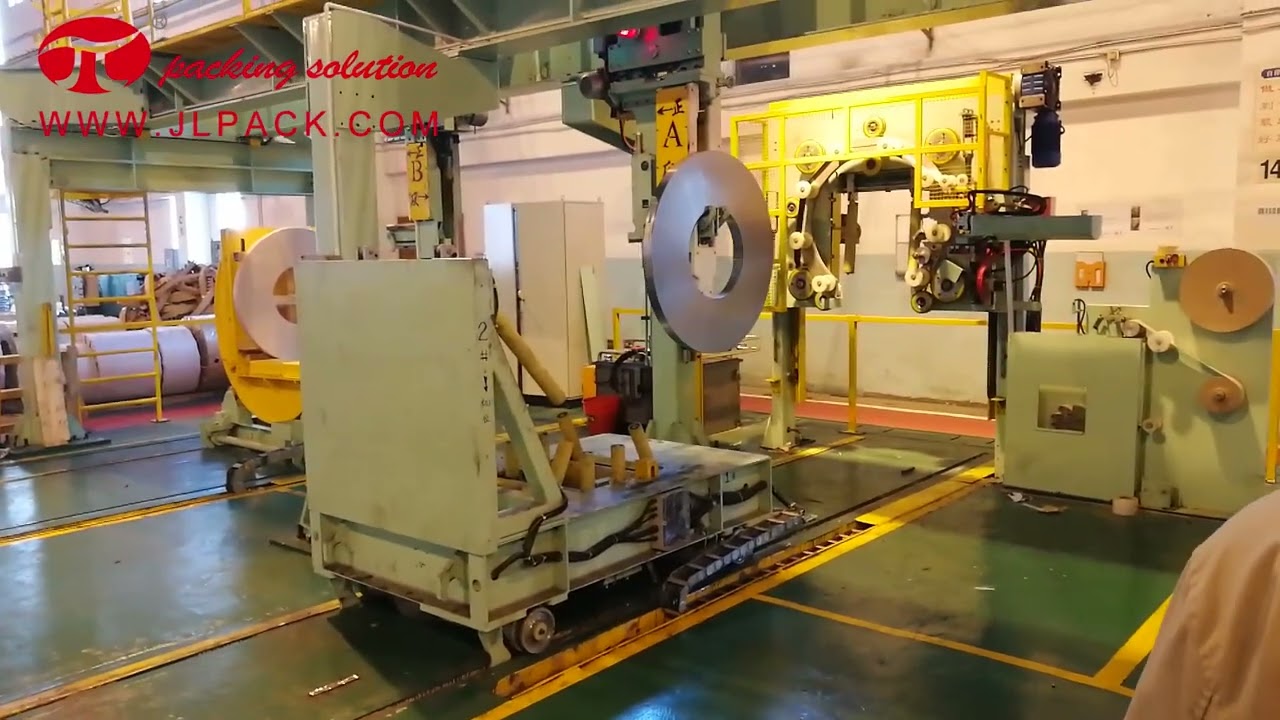

The coil packing line is a sophisticated piece of equipment that encompasses several stages of the packaging process. From feeding the coils onto the line to their final packaging, these lines ensure a seamless and automated operation. The equipment used in these lines is designed specifically for coil packaging and is capable of handling different coil sizes and weights.

One notable company offering high-quality Steel Wire Coil Packing Equipment from Basket to Coils is Emanpack. Their state-of-the-art packaging lines are known for their reliability, durability, and efficiency. With a focus on customer satisfaction, Emanpack has revolutionized the coil packaging industry, providing innovative solutions for manufacturers worldwide.

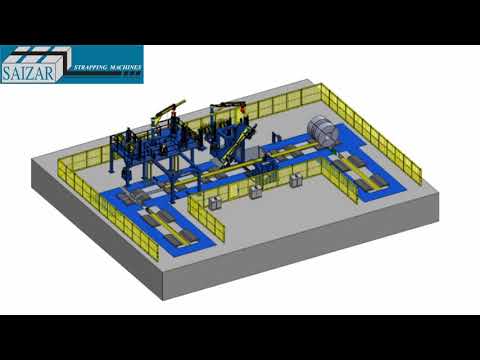

The coil packing line consists of several components, each with a specific role in the packaging process. The first step is the feeding of the coils onto the line. This can be done manually or through an automated system, depending on the requirements of the manufacturer. Once the coils are on the line, they pass through various stages, including strapping, wrapping, and labeling.

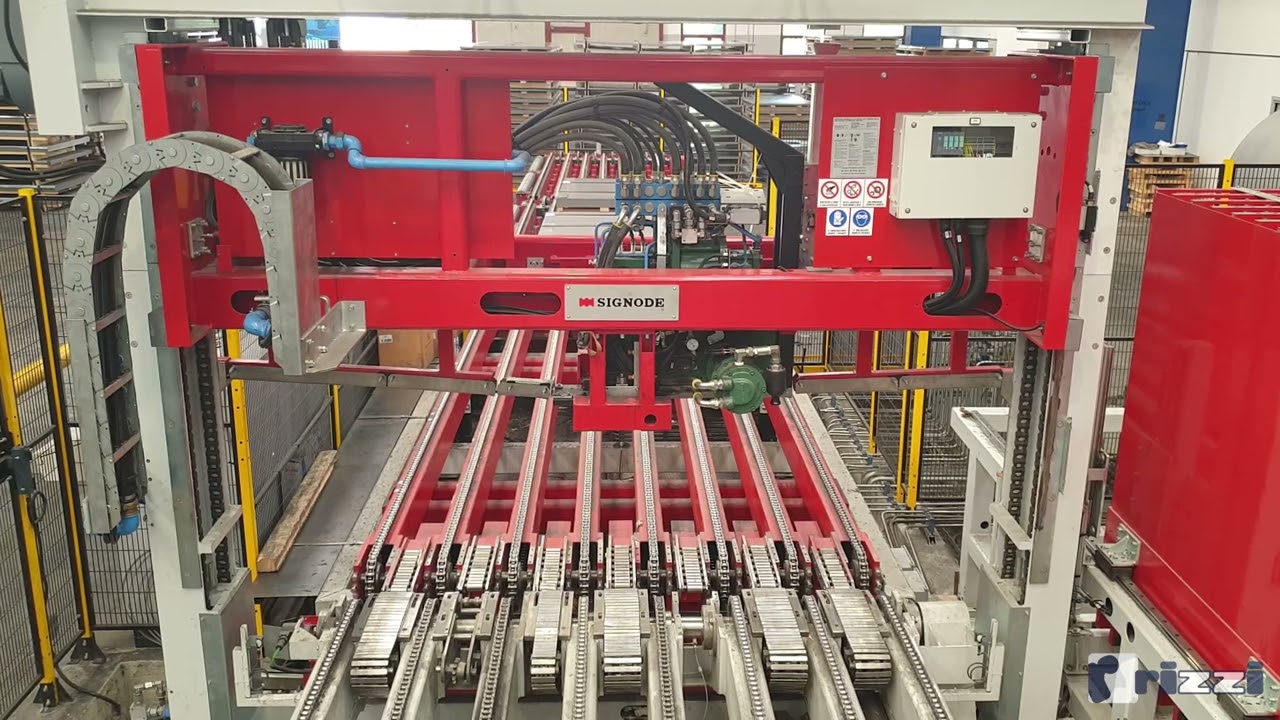

Strapping is a crucial step in ensuring the stability and security of the coils. The coil packing line is equipped with strapping machines that securely fasten the coils using high-quality straps. These straps are adjustable, allowing manufacturers to customize the tension according to their specific needs. The strapping process is automated, eliminating the need for manual labor and reducing the risk of errors.

After the strapping process, the coils move on to the wrapping stage. The coil packing line features advanced wrapping machines that tightly wrap the coils with stretch film. This film provides an additional layer of protection, safeguarding the coils against dust, moisture, and other external factors. The wrapping process is carefully controlled, ensuring optimal tension and coverage, resulting in a secure and uniform packaging.

Labeling is another crucial step in the packaging process, allowing for easy identification and tracking of the coils. The coil packing line is equipped with labeling machines that print and apply labels to each coil. These labels can include important information such as product details, batch numbers, and barcodes. By automating the labeling process, manufacturers can ensure accurate and consistent labeling, enhancing traceability and inventory management.

In addition to the core packaging stages, coil packing lines often include additional features and capabilities. For example, some lines offer automatic weighing systems that accurately measure the weight of each coil. This information is invaluable for inventory management and quality control purposes. Moreover, some lines incorporate conveyor systems that facilitate the movement of coils between different stages, further enhancing the efficiency of the packaging process.

The advent of coil packing lines has significantly transformed the steel wire coil packaging industry. Manufacturers can now benefit from increased productivity, reduced labor costs, and improved packaging quality. The automation of the packaging process eliminates human errors and ensures consistent results. Moreover, the advanced features of coil packing lines enhance the overall efficiency and effectiveness of the packaging process.

As the demand for steel wire coils continues to rise, it is crucial for manufacturers to invest in reliable and efficient packaging solutions. Coil packing lines, such as the Steel Wire Coil Packing Equipment from Basket to Coils offered by Emanpack, provide a comprehensive solution that meets the needs of modern-day manufacturing. With their innovative features and advanced technologies, these lines streamline the packaging process, allowing manufacturers to meet market demands effectively.

In conclusion, coil packing lines have revolutionized the steel wire coil packaging industry. With their advanced technologies and innovative features, these lines streamline the packaging process and offer numerous benefits to manufacturers. The Steel Wire Coil Packing Equipment from Basket to Coils, offered by companies like Emanpack, ensures efficient and effective packaging, providing increased productivity and improved packaging quality. By investing in these cutting-edge solutions, manufacturers can stay ahead in the competitive market and meet the growing demands of their customers.

coil packing line

"Efficient Steel Wire Coil Packing Equipment: Streamlining the Process from Basket to Coils with a State-of-the-Art Coil Packing Line"