Metal Slit Coil Packaging Line: How to Achieve Automatic Coil Packing

In today’s fast-paced industrial world, efficiency and productivity are key factors in determining the success of a company. One area where these factors play a significant role is in the packaging of metal slit coils. The process of coil packing requires precision, speed, and reliability to ensure that the final product reaches its destination in optimal condition. In this article, we will explore the innovative technology behind a steel coil packaging line and how it enables the automatic packing of metal slit coils.

The steel coil packaging line is a state-of-the-art solution that revolutionizes the traditional manual packing process. It boasts cutting-edge technology, providing a seamless and efficient packaging experience. This automated system eliminates the need for human intervention, reducing the risk of errors and increasing overall productivity.

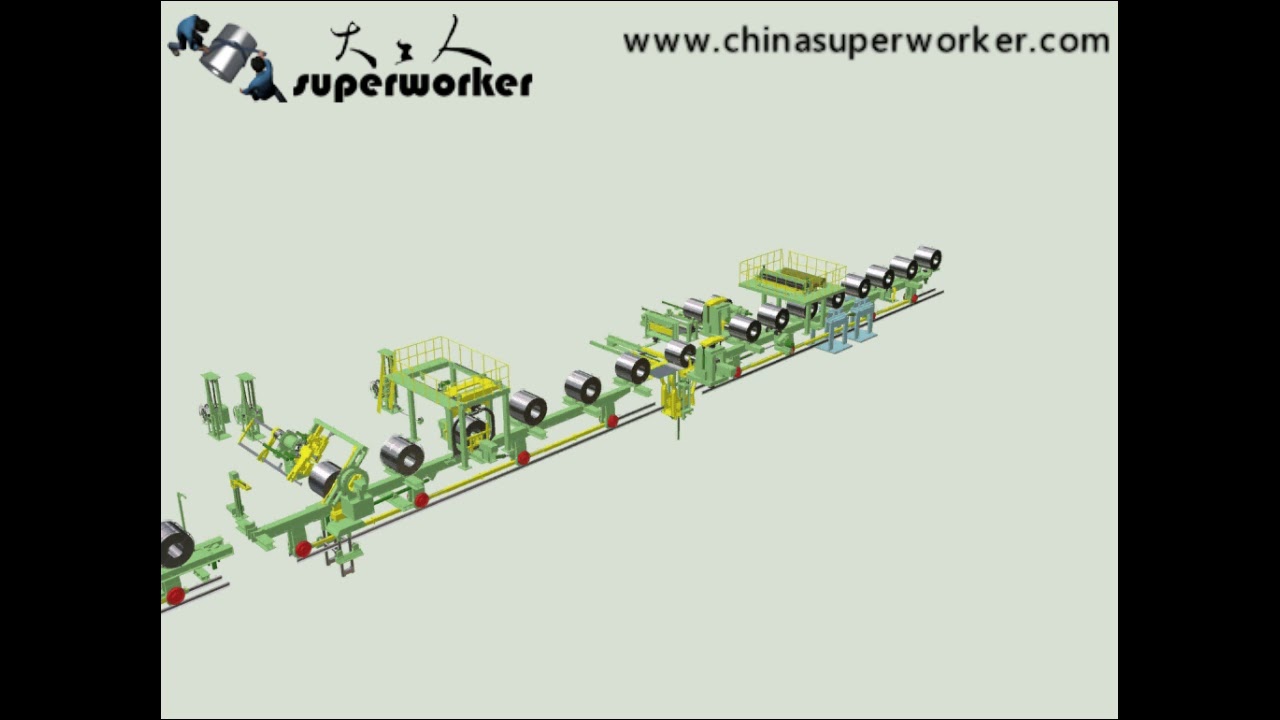

The coil packing line begins with an introduction and a brief overview of its features and capabilities. This initial step sets the stage for what is to come, piquing the interest of potential customers who are seeking a reliable and advanced solution for their coil packaging needs.

Utilizing advanced machinery and intelligent control systems, the coil packing line streamlines the entire packaging process. It starts by automatically feeding the metal slit coils onto a conveyor belt, ensuring a continuous and smooth flow. This eliminates the need for manual handling, reducing the risk of damage to the coils and increasing overall efficiency.

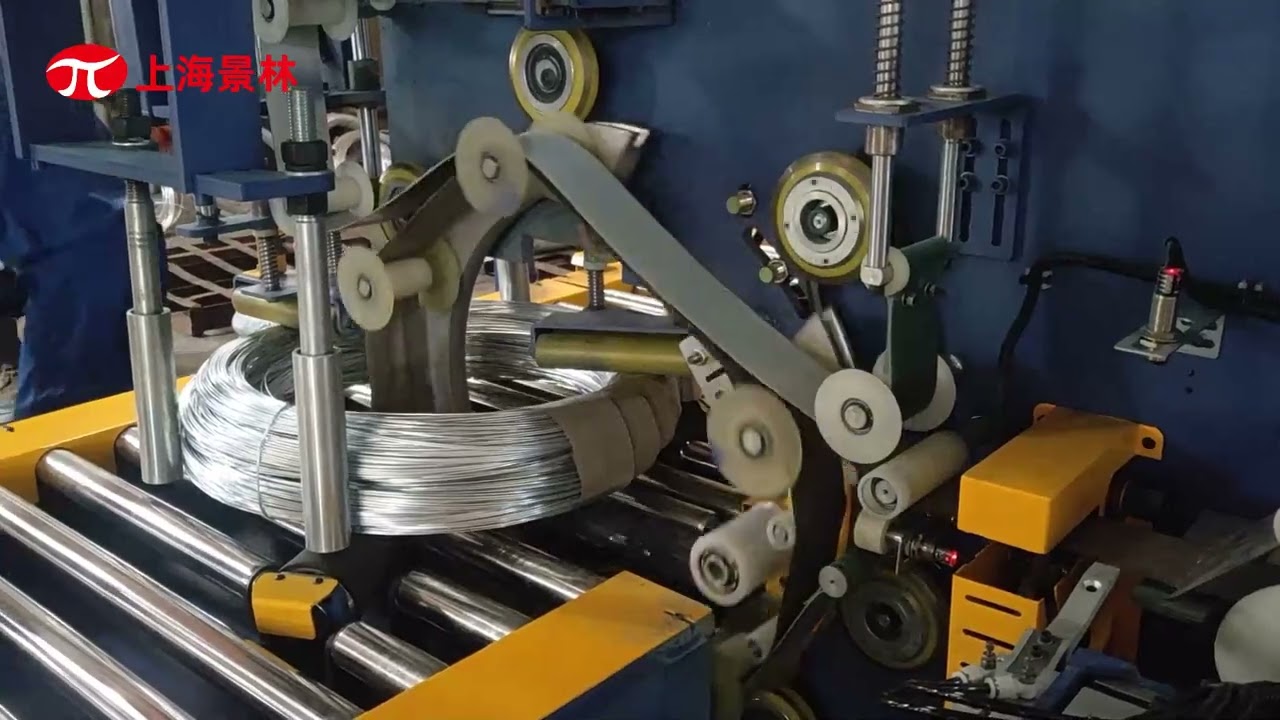

Once the coils are on the conveyor belt, they pass through a series of stages that prepare them for packaging. The line includes a coil wrapper, which tightly wraps the coils with a protective film. This film serves as a barrier against moisture, dust, and other external factors that could potentially affect the quality of the coils during transportation or storage.

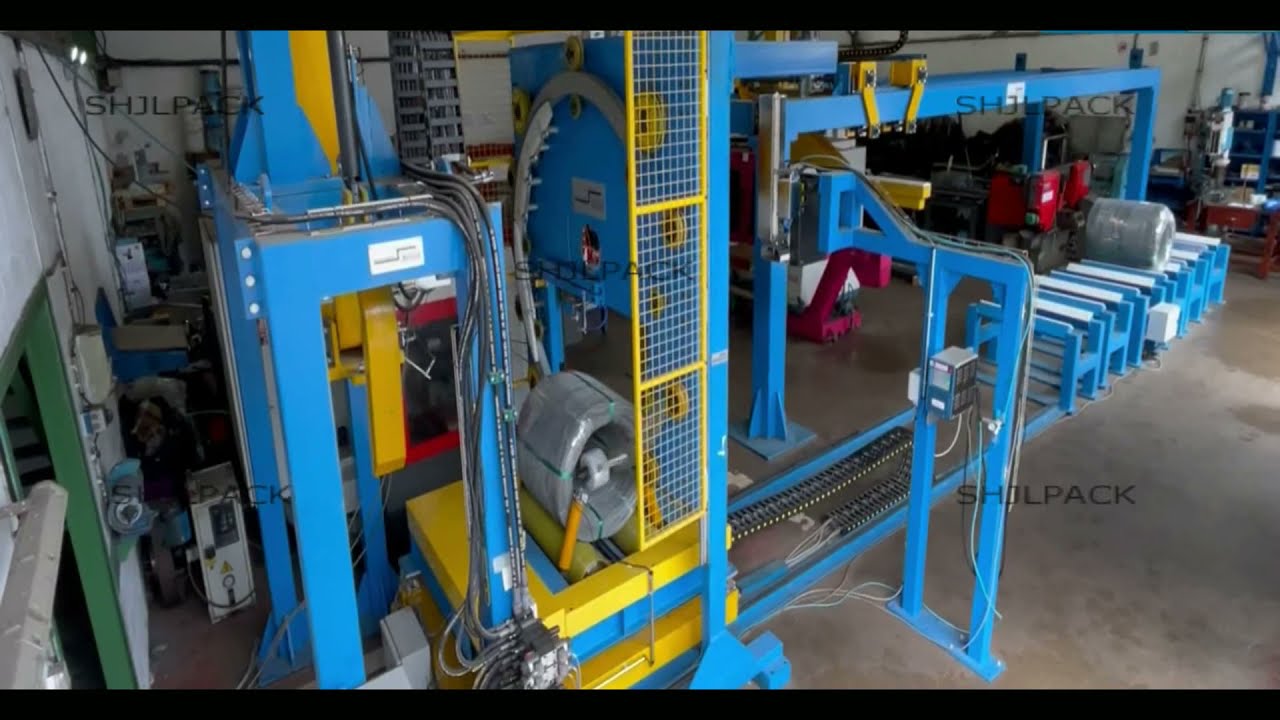

Additionally, the coil packing line incorporates an automatic strapping machine. This machine securely fastens the wrapped coils, ensuring that they remain intact and stable throughout the entire packaging process. By eliminating the need for manual strapping, this feature saves time and reduces the risk of human error.

One of the standout features of the coil packing line is its user-friendly interface. With a simple and intuitive control panel, operators can easily monitor and adjust the packaging process according to their specific requirements. This feature allows for efficient customization and ensures that the final product meets the highest quality standards.

Another noteworthy aspect of the coil packing line is its versatility. It is capable of handling different coil sizes and weights, making it suitable for a wide range of applications. Whether it’s stainless steel, aluminum, or any other metal material, this packaging line can adapt to the specific needs of the customer, further enhancing its value and flexibility.

Moreover, the coil packing line prioritizes safety. It is equipped with advanced sensors and safety devices that detect any abnormalities or potential hazards during the packaging process. This ensures the well-being of the operators and prevents any damage to the machinery or the coils themselves.

In conclusion, the steel coil packaging line is a game-changer in the industry, offering a revolutionary solution for automatic coil packing. Its advanced technology, user-friendly interface, and versatility make it an invaluable asset for companies seeking to streamline their packaging processes and increase overall productivity. By eliminating manual handling, reducing human error, and ensuring the highest quality standards, this innovative system paves the way for a more efficient and reliable coil packaging experience.

coil packing line

“Efficient and Automated Slitting Coil Packing: Streamlining Processes with a Cutting-edge Packaging Line”