Coil Packing Line: The Ultimate Solution for Efficient Packaging

The coil packaging industry has witnessed significant advancements over the years, thanks to the introduction of innovative technologies and machinery. One such remarkable invention is the pomacon autobander, a state-of-the-art machine that revolutionizes the coil packing process. In this article, we delve into the intricacies of the pomacon autobander and its role in streamlining coil packaging operations.

The pomacon autobander, integrated into the coil packing line, is designed to automate and optimize the coil packaging process. This cutting-edge machine offers a range of features and functions that enhance efficiency, productivity, and reliability. It eliminates the need for manual labor, reducing the risk of human error and ensuring consistent and precise packaging results.

With the coil packaging industry witnessing rapid growth, the demand for a reliable and efficient packaging solution has never been greater. The pomacon autobander, with its advanced capabilities, meets this demand head-on. It is capable of handling a wide range of coil sizes, making it a versatile choice for various industries, including automotive, steel, and construction.

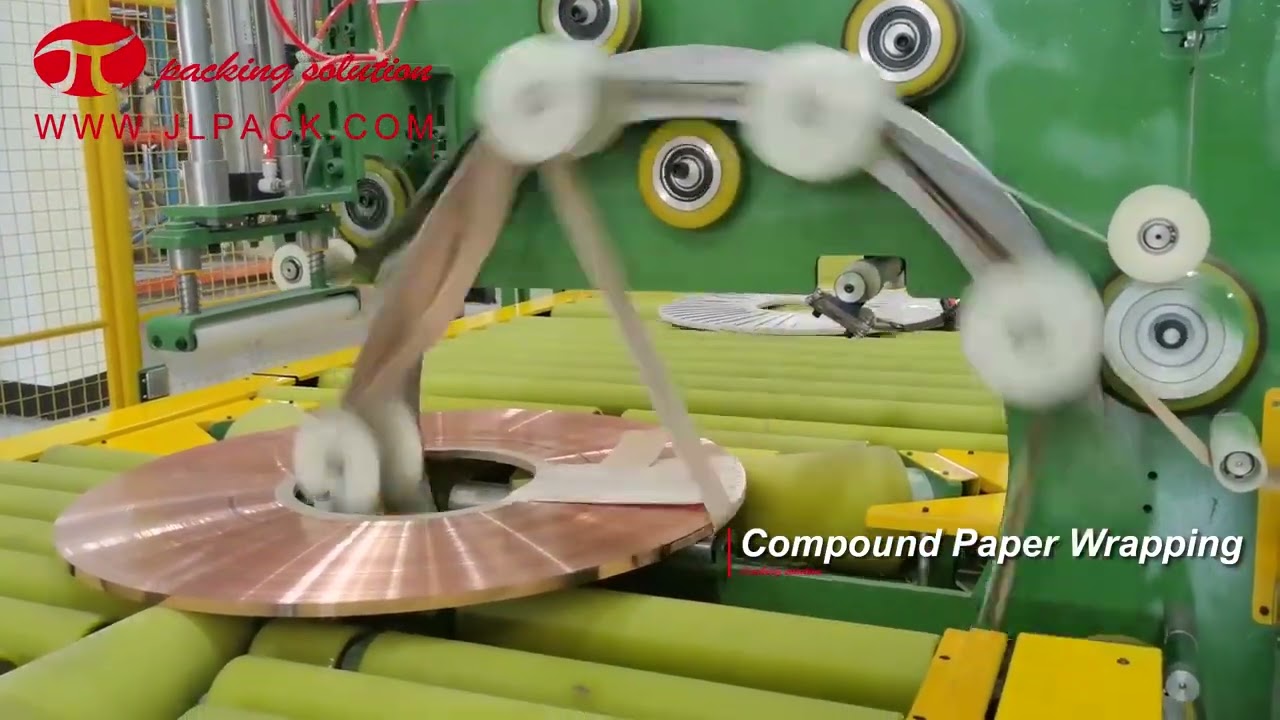

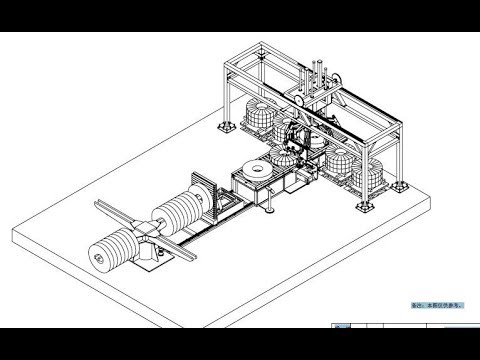

The coil packing line, equipped with the pomacon autobander, offers a seamless and integrated packaging process. It starts with the loading of coils onto the line, where they are carefully positioned for further processing. The coils then pass through various stages, including strapping, wrapping, and labeling, before reaching the final packaging stage.

The pomacon autobander utilizes cutting-edge technology to ensure precise and secure strapping of coils. It can automatically adjust the tension and positioning of the straps, guaranteeing optimal bundling and preventing any damage during transportation. This not only enhances the safety of the packaged coils but also minimizes the risk of product loss or damage.

Furthermore, the coil packing line is equipped with advanced sensors and control systems, ensuring that each coil is packaged according to the required specifications. The autobander can be easily programmed to accommodate different coil dimensions, ensuring a customized packaging solution for every requirement. This flexibility is a significant advantage, as it allows companies to adapt to changing market demands and efficiently package their products.

The pomacon autobander also addresses environmental concerns by minimizing material wastage. It optimizes the use of strapping materials, reducing unnecessary consumption and lowering packaging costs. Moreover, the autobander ensures that the straps are securely fastened, eliminating the risk of them becoming loose or detached during transit.

In addition to its exceptional performance, the pomacon autobander offers user-friendly controls and interfaces. Its intuitive design allows operators to easily monitor and adjust the packaging process, ensuring smooth operations and minimizing downtime. The machine's reliability and ease of use contribute to increased overall productivity and customer satisfaction.

Companies that have integrated the pomacon autobander into their coil packing lines have witnessed exponential improvements in their packaging operations. The machine's efficiency and accuracy have translated into shorter lead times, reduced labor costs, and higher output. This not only enhances the company's bottom line but also strengthens its competitiveness in the market.

As the coil packaging industry continues to evolve, the pomacon autobander stands at the forefront of innovation. Its advanced features, coupled with its ability to seamlessly integrate into existing coil packing lines, make it a game-changer in the industry. By embracing this cutting-edge technology, companies can optimize their packaging processes and stay ahead of the competition.

In conclusion, the pomacon autobander, integrated into the coil packing line, offers a comprehensive solution for efficient and reliable coil packaging. Its advanced capabilities, user-friendly interface, and versatility make it a valuable asset for companies across various industries. By investing in this state-of-the-art machine, businesses can streamline their packaging operations, enhance productivity, and deliver superior quality products to their customers. The pomacon autobander is indeed a game-changer in the coil packaging industry, paving the way for a new era of efficiency and innovation.

coil packing line

"Optimizing Efficiency: Enhancing Slit Coil Packaging with Advanced Technology"