Automatic Copper Coil Packing Line: Revolutionizing Efficiency in the Packaging Industry

In today’s fast-paced world, efficiency is the name of the game. Companies across various industries are constantly searching for ways to streamline their processes and maximize productivity. The packaging industry is no exception. With the increasing demand for faster and more efficient packaging solutions, the introduction of the High Efficiency Copper Coil Automatic Packing Line is a game-changer.

The coil packing line has revolutionized the way copper coils are packaged, making the process faster, more reliable, and cost-effective. This cutting-edge technology has caught the attention of many industry experts, who are praising its ability to significantly improve productivity and reduce labor costs.

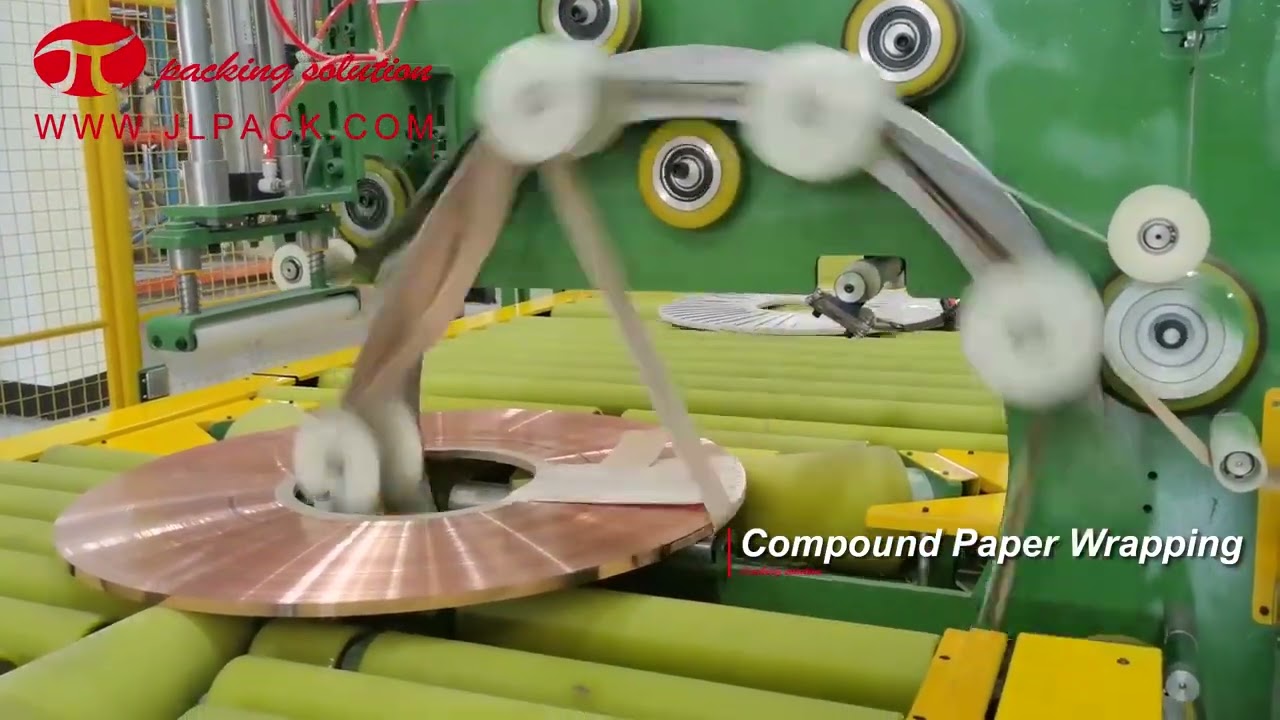

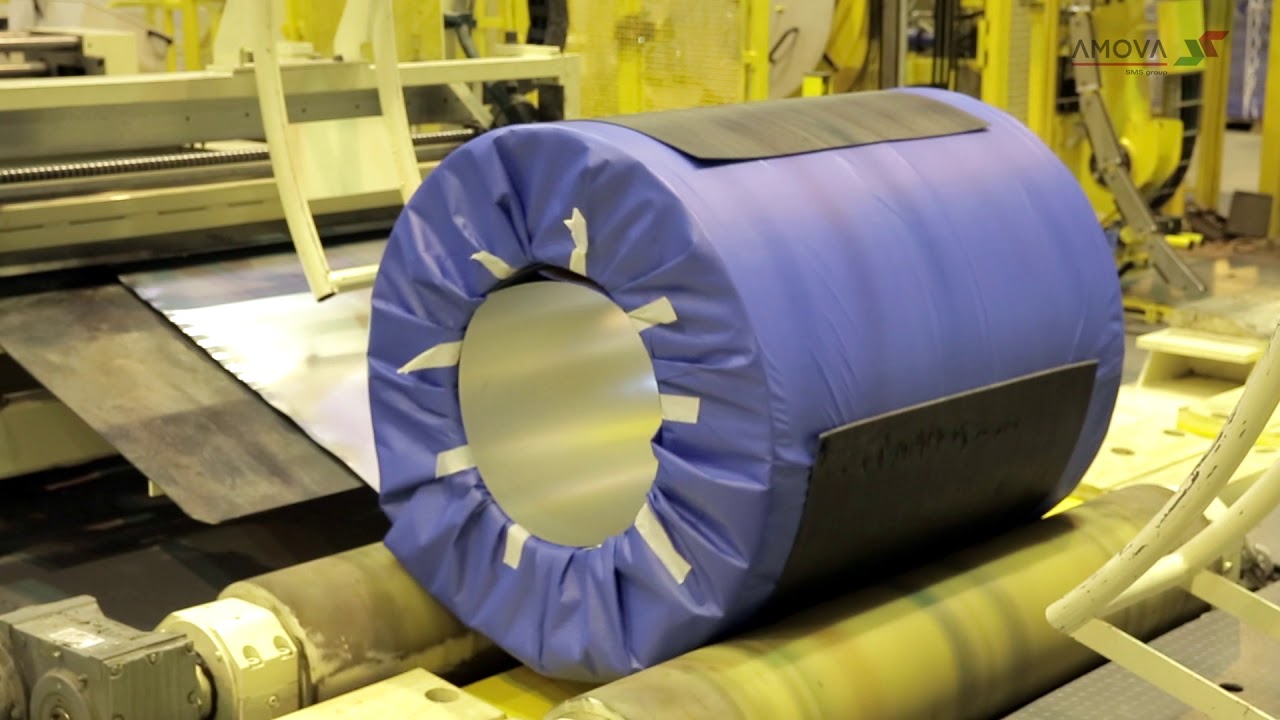

The High Efficiency Copper Coil Automatic Packing Line utilizes a compound paper packaging material, which provides excellent protection for the delicate copper coils. This compound paper is specifically designed to withstand the rigors of transportation and storage, ensuring that the coils reach their destination in pristine condition.

One of the key features of this automatic packing line is its ability to handle large volumes of copper coils with minimal human intervention. This not only saves time but also reduces the risk of human error, ensuring consistent and reliable packaging quality. The line is equipped with state-of-the-art sensors and control systems that monitor the packaging process in real-time, making adjustments as needed to ensure optimal performance.

Furthermore, this innovative packing line is designed to be highly versatile, capable of handling various coil sizes and shapes. Whether it’s small coils or large ones, the system can be easily adjusted to accommodate different specifications, making it an ideal solution for companies with diverse packaging needs.

The High Efficiency Copper Coil Automatic Packing Line has also garnered attention for its energy efficiency. With advanced power-saving features, the system reduces overall energy consumption, contributing to a greener and more sustainable packaging process. This is a significant advantage for companies looking to minimize their environmental footprint while maximizing their operational efficiency.

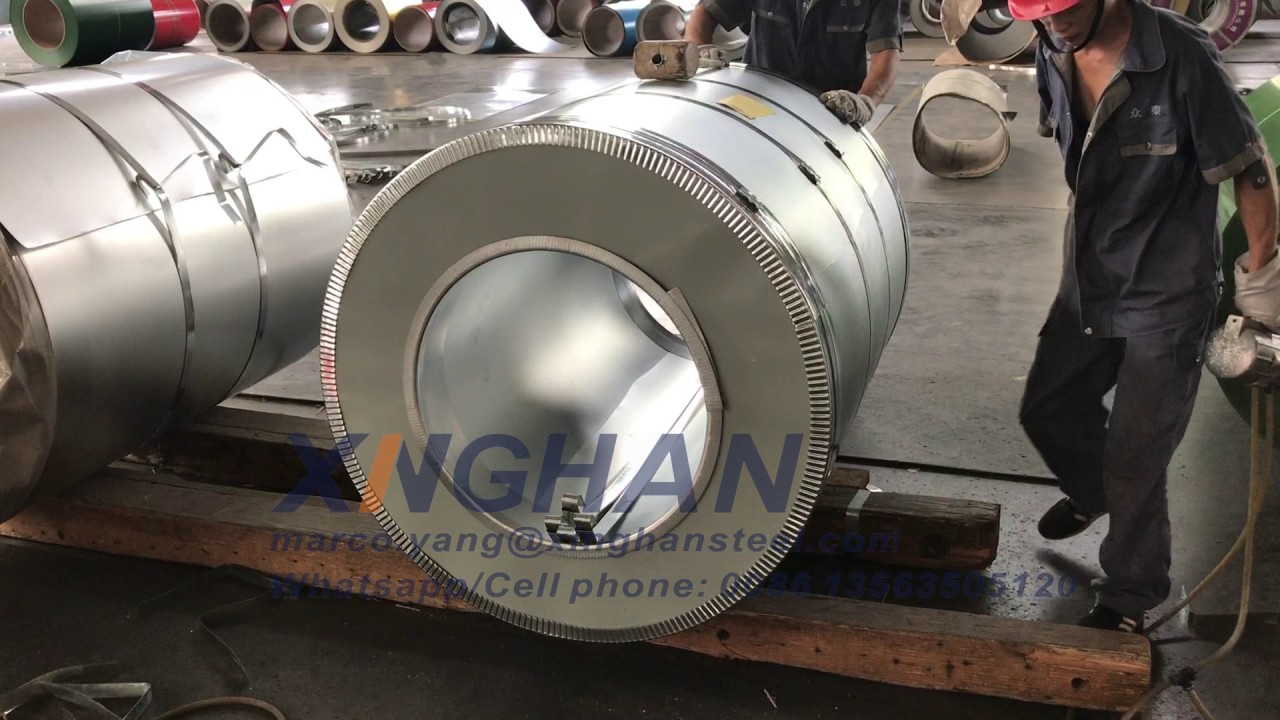

To understand the impact of this automatic packing line, let’s take a closer look at a case study. Company X, a leading manufacturer of copper coils, was facing challenges in meeting their increasing packaging demands. Their manual packaging process was not only time-consuming but also prone to errors, leading to delays and customer dissatisfaction.

Upon implementing the High Efficiency Copper Coil Automatic Packing Line, Company X witnessed a remarkable transformation. The line’s speed and precision significantly improved their packaging efficiency, allowing them to meet tight deadlines and exceed customer expectations. The reduction in labor costs also contributed to substantial savings for the company.

Industry experts are predicting that this technology will continue to evolve and revolutionize the packaging industry. Its potential applications extend beyond copper coils, with possibilities for packaging various other products that require a high level of protection and efficiency.

In conclusion, the High Efficiency Copper Coil Automatic Packing Line is a game-changer for the packaging industry. Its ability to streamline the packaging process, improve efficiency, and reduce costs has made it a highly sought-after solution for companies across the globe. With its versatility, energy efficiency, and ability to handle large volumes, this automatic packing line is paving the way for a more efficient and sustainable future in packaging.

coil packing line

“Streamlining Copper Coil Packaging with an Efficient Automatic Line”