Automating the Packaging Process with an Automatic Metal Coil Packing Line

Packaging plays a crucial role in ensuring the safe transportation and storage of various products. In industries such as manufacturing and logistics, the packaging process needs to be efficient, reliable, and cost-effective. Shanghai Jinglin Packaging Machinery Co., Ltd. understands these requirements and has developed an innovative solution – the Automatic Metal Coil Packing Line. This state-of-the-art machinery revolutionizes the way metal coils are packaged, making the process quicker, more consistent, and ultimately more profitable.

The Automatic Metal Coil Packing Line offered by Shanghai Jinglin Packaging Machinery Co., Ltd. is a game-changer for companies dealing with metal coils. This automated system effectively eliminates the need for manual labor, reducing the risk of human error and increasing overall productivity. With this advanced technology in place, companies can experience significant improvements in their packaging operations.

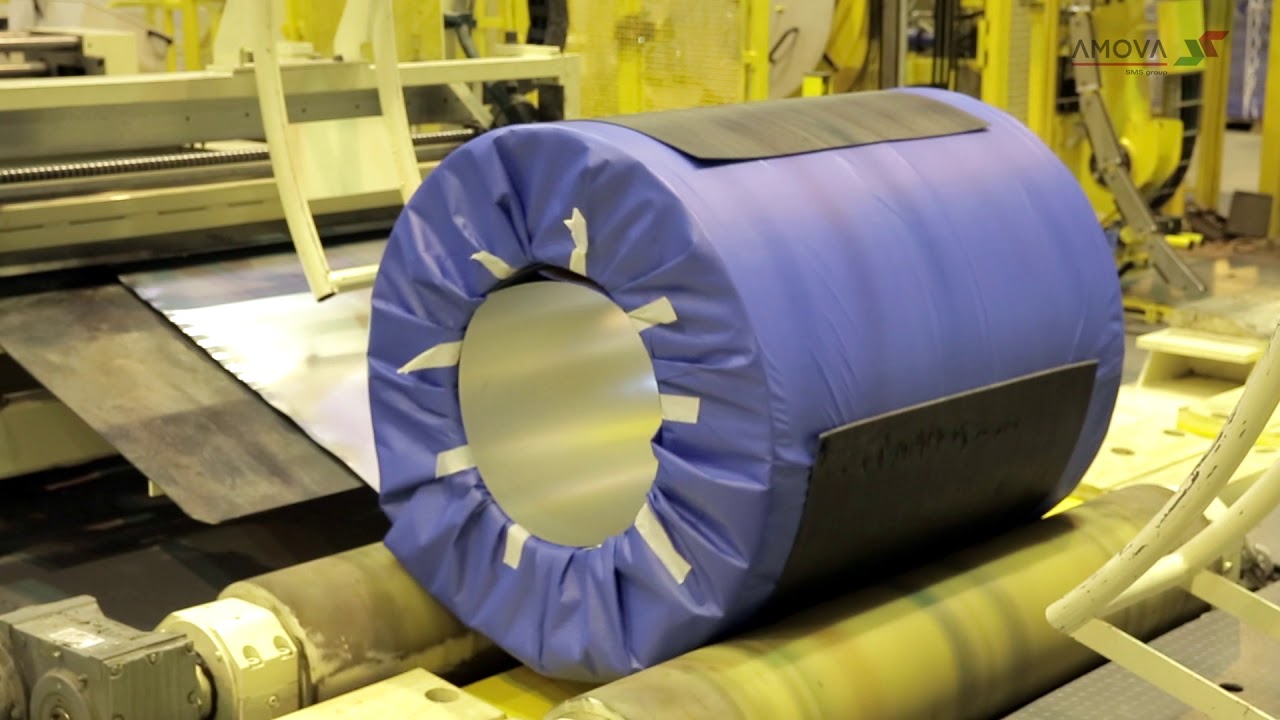

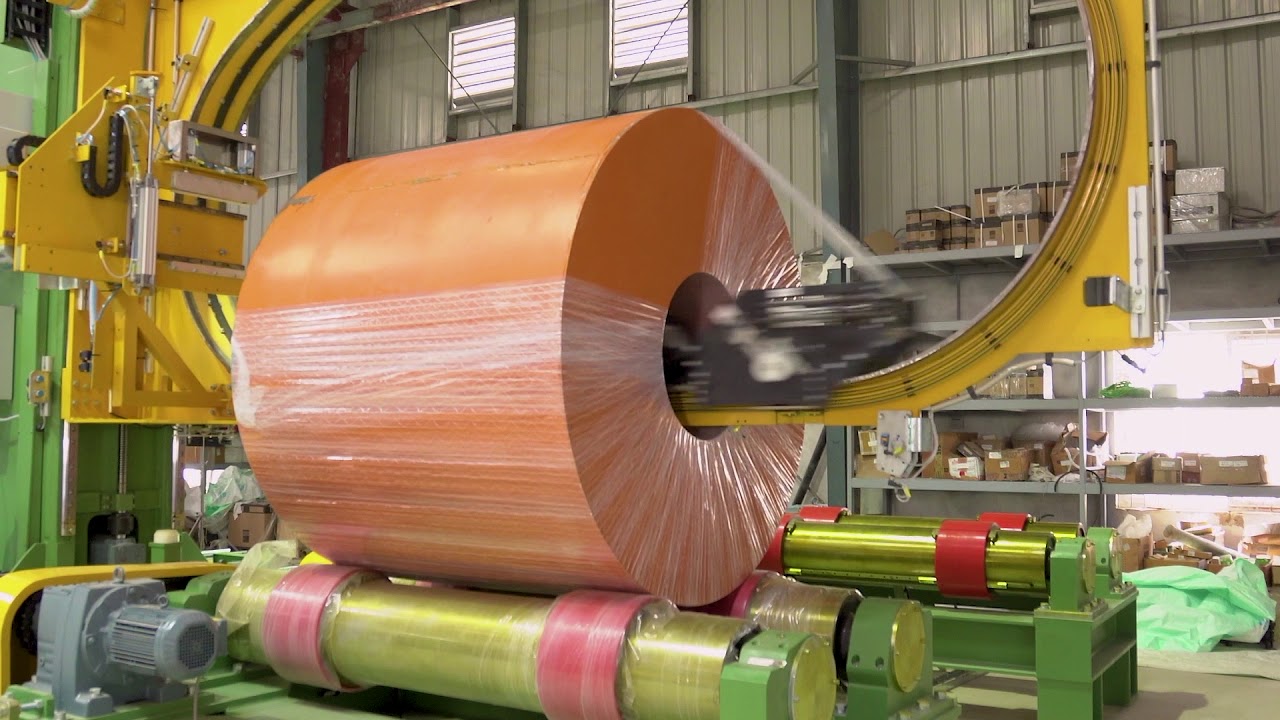

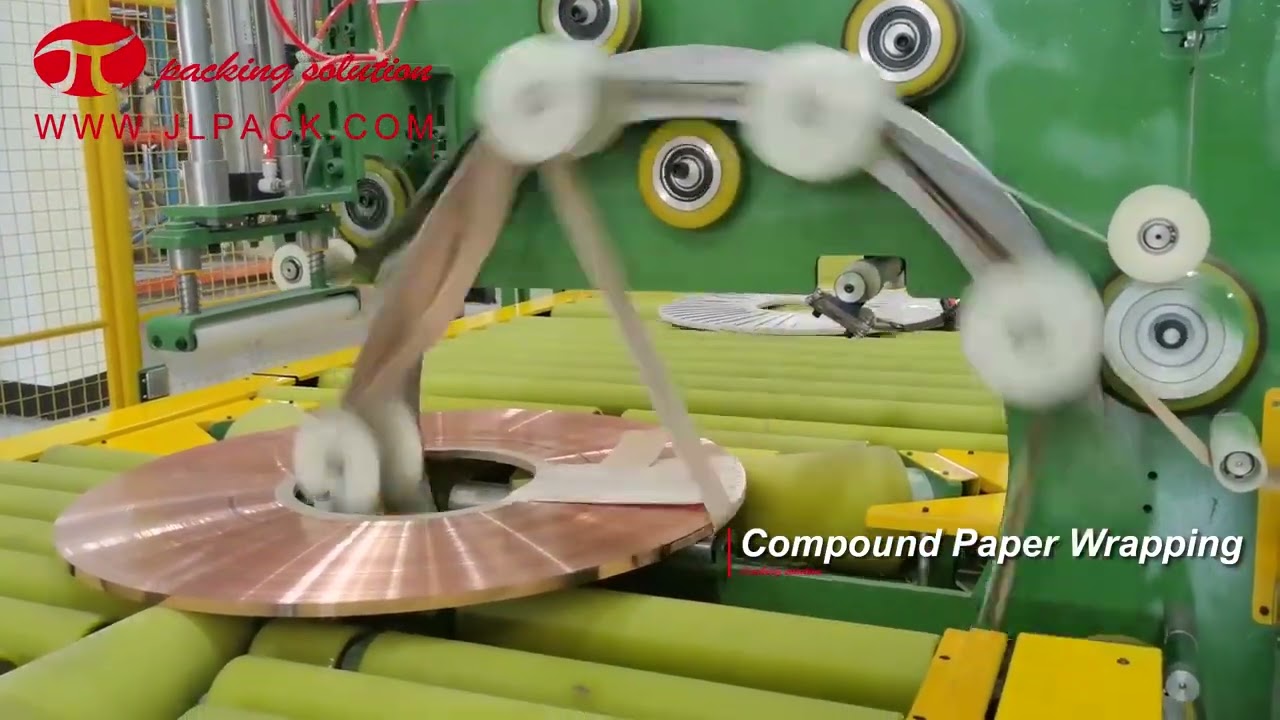

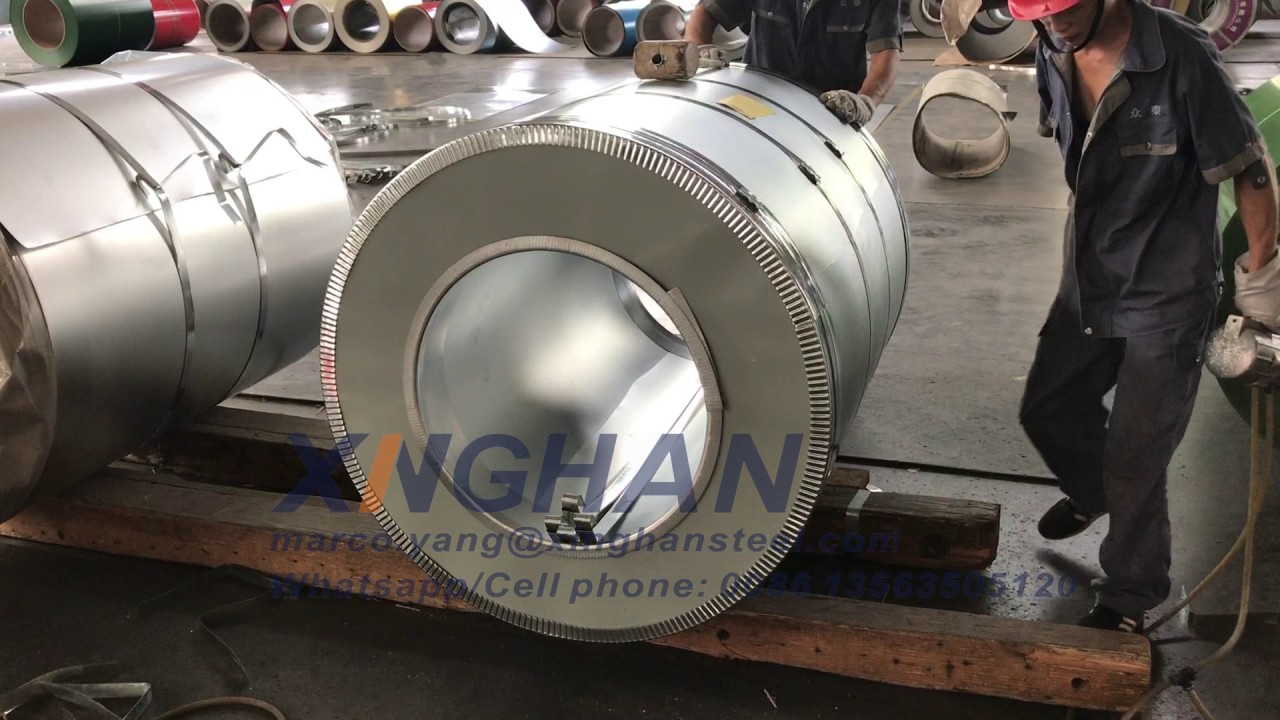

One of the key benefits of the Automatic Metal Coil Packing Line is its ability to ensure consistent and secure packaging. The system is designed to wrap metal coils with precision, using high-quality materials that provide adequate protection during transportation and storage. This eliminates the possibility of damage or scratches, ensuring that the coils reach their destination in pristine condition.

The Automatic Metal Coil Packing Line also offers flexibility in terms of customization. Companies can adjust the packaging parameters according to their specific requirements, such as coil size, weight, and shape. This adaptability allows for a seamless integration of the machinery into existing production lines, making it a cost-effective solution for businesses of all sizes.

Furthermore, the Automatic Metal Coil Packing Line enhances safety in the packaging process. By eliminating the need for manual handling, the risk of accidents and injuries is significantly minimized. This not only protects employees but also reduces the expenses associated with workplace accidents, including medical costs and potential legal liabilities.

In addition to its practical benefits, the Automatic Metal Coil Packing Line also contributes to environmental sustainability. The system is designed to optimize material usage, minimizing waste and reducing the carbon footprint. This aligns with the growing global focus on eco-friendly practices, allowing companies to improve their sustainability credentials while maintaining operational efficiency.

The success of the Automatic Metal Coil Packing Line can be attributed to Shanghai Jinglin Packaging Machinery Co., Ltd.'s commitment to quality and innovation. With years of experience in the packaging industry, the company has developed a reputation for delivering reliable and cutting-edge solutions. Their dedication to customer satisfaction is evident in the design and functionality of the Automatic Metal Coil Packing Line.

As a result, the Automatic Metal Coil Packing Line has received positive feedback from customers who have integrated it into their operations. Companies praise its efficiency, reliability, and ease of use, emphasizing the significant improvements in productivity and cost savings they have experienced. By automating the packaging process, businesses can allocate their resources more efficiently, focusing on core activities and driving overall growth.

In conclusion, Shanghai Jinglin Packaging Machinery Co., Ltd.'s Automatic Metal Coil Packing Line is a game-changer for companies in need of efficient and reliable packaging solutions. By automating the process, this innovative machinery enhances productivity, consistency, and safety while reducing costs and environmental impact. With its customizable features and commitment to quality, Shanghai Jinglin Packaging Machinery Co., Ltd. has once again proven itself as a leader in the packaging industry.

coil packing line

"Efficient Metal Coil Packing Line: Streamlining Packaging Process for Enhanced Productivity"