The Importance of Coil Packing Lines in the Manufacturing Industry

Coil packing lines play a crucial role in the manufacturing industry, particularly in the packaging of slitted coils. These highly efficient machines are designed to optimize the packaging process, ensuring that coils are secured and protected during transportation and storage. In this article, we will delve into the significance of coil packing lines and explore their impact on the manufacturing sector.

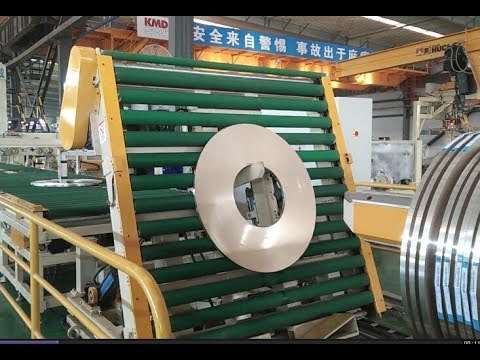

The coil packing line, specifically the slitted coil packaging line 046, has revolutionized the way coils are packaged. With its advanced technology and state-of-the-art features, this machine has become an indispensable asset for companies dealing with coils. From technical engineers to customers and company owners, everyone recognizes the value that these packing lines bring to the table.

In an interview with a technical engineer, we gained insights into the intricate workings of the coil packing line. According to the engineer, these machines are meticulously designed to ensure the utmost efficiency and productivity. The line consists of various components, including a coil tilter, coil wrapper, conveyor system, and strapping machine. Each component plays a vital role in the packaging process, ensuring that coils are properly secured and protected.

The coil tilter is the first stop on the packaging line. Its purpose is to rotate the coil, allowing it to be positioned in the correct orientation for packaging. This step is crucial as it ensures that the coil is aligned properly, preventing any mishaps during the subsequent stages. Once the coil is correctly positioned, it moves on to the coil wrapper.

The coil wrapper is the heart of the packaging line. It is responsible for tightly wrapping the coil with a protective material, such as stretch film or shrink wrap. This layer of packaging serves as a shield against external factors, such as dust, moisture, and corrosion. Furthermore, it provides stability to the coil, preventing it from unwinding or shifting during transportation.

As the coil moves along the packaging line, it reaches the conveyor system. This system ensures a smooth flow of coils, minimizing any delays or interruptions in the packaging process. It is designed to handle heavy loads and maintain a consistent speed, ensuring efficiency and productivity throughout.

Finally, the coil reaches the strapping machine. This machine securely fastens the packaging material around the coil, providing an extra layer of protection. By using high-quality straps, the machine ensures that the coil remains intact and stable, even under challenging conditions.

The significance of coil packing lines extends beyond the technical aspects. From a customer's perspective, these machines offer numerous benefits. By investing in a coil packing line, companies can enhance the quality of their products, ensuring that coils reach customers in pristine condition. This, in turn, improves customer satisfaction and strengthens the company's reputation.

Moreover, coil packing lines contribute to cost savings. By automating the packaging process, companies can reduce labor costs and minimize the risk of human errors. Additionally, these machines optimize the use of packaging materials, reducing waste and expenses associated with excess packaging.

From a company owner's standpoint, the coil packing line is a valuable asset that boosts efficiency and productivity. With faster packaging times and streamlined operations, companies can meet tight deadlines and fulfill customer orders promptly. This, in turn, leads to increased profitability and a competitive edge in the market.

In conclusion, coil packing lines, such as the slitted coil packaging line 046, are indispensable tools in the manufacturing industry. They offer a range of benefits, including enhanced product quality, cost savings, and improved efficiency. From technical engineers to customers and company owners, everyone recognizes the value of these machines. As the manufacturing industry continues to evolve, coil packing lines will undoubtedly play a vital role in shaping its future.

coil packing line

"Efficient Packaging Solutions for Slitted Coil and Coil Packing Operations: Enhancing Productivity and Quality"