Mosquito Coil Packaging Line: The Ultimate Solution for Efficient Production

In today’s fast-paced world, industries are constantly seeking innovative ways to improve their production processes. One such industry is the mosquito coil manufacturing industry, where the demand for effective and efficient packaging solutions is on the rise. In this article, we will explore the benefits of a coil packing line and how it revolutionizes the packaging process for mosquito coils.

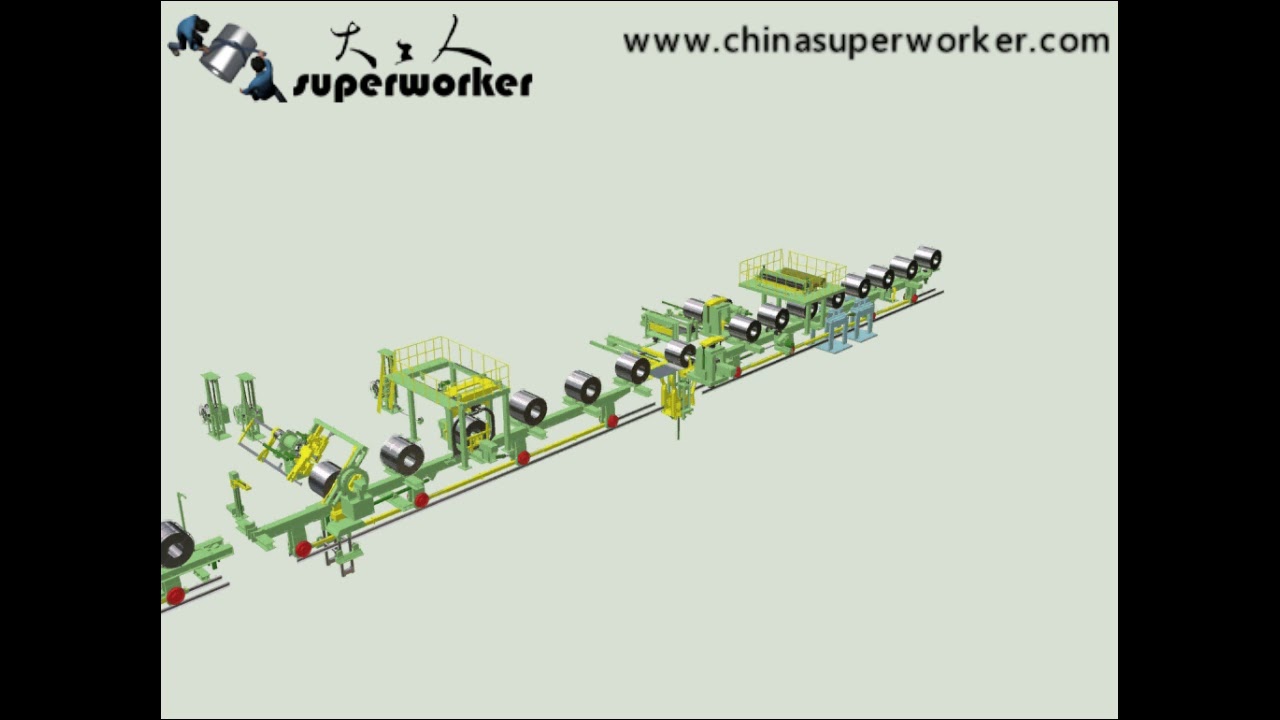

The Mosquito Coil Packaging Line is a state-of-the-art system that combines the Pillow Bag Packing Machine with the Cartoning Machine, creating a seamless and automated packaging process. This integration not only ensures the efficient packaging of mosquito coils but also enhances productivity and reduces manual labor.

The Pillow Bag Packing Machine is the first component of the coil packing line. This machine is designed to pack the mosquito coils into pillow-shaped bags, which not only provide protection but also serve as an attractive packaging option. With its advanced technology, this machine can accurately measure and fill the coils into the bags, ensuring consistent and precise packaging.

The second component of the coil packing line is the Cartoning Machine. This machine takes the pillow-shaped bags filled with mosquito coils and automatically places them into cartons. The cartons are then sealed and ready for distribution. This automated process eliminates the need for manual labor, saving time and reducing the risk of human error.

One of the key advantages of the coil packing line is its high-speed operation. With its advanced technology and efficient design, this production line can handle a large volume of mosquito coils in a short period. This not only increases productivity but also meets the growing demands of the market.

Moreover, the coil packing line ensures consistent and uniform packaging. The automated process guarantees that each pillow bag is filled with the same amount of mosquito coils, maintaining product quality and customer satisfaction. Additionally, the cartoning machine ensures that each carton is properly sealed, preventing any damage or contamination during transportation.

Another significant benefit of the coil packing line is its versatility. It can accommodate different sizes and types of mosquito coils, allowing manufacturers to cater to various customer preferences. This flexibility ensures that the packaging process is adaptable and can meet the changing needs of the market.

Furthermore, the coil packing line promotes cost-efficiency. By automating the packaging process, manufacturers can significantly reduce labor costs. The machines operate with minimal human intervention, reducing the need for a large workforce. Additionally, the high-speed operation of the coil packing line increases production output, maximizing the return on investment for manufacturers.

In conclusion, the Mosquito Coil Packaging Line is a game-changer for the mosquito coil manufacturing industry. Its integration of the Pillow Bag Packing Machine and the Cartoning Machine revolutionizes the packaging process, ensuring efficiency, productivity, and cost-effectiveness. With its high-speed operation, consistent packaging, versatility, and cost-efficiency, the coil packing line is the ultimate solution for manufacturers seeking to streamline their production processes. Embracing this innovative technology will undoubtedly propel the mosquito coil industry into a new era of success and growth.

coil packing line

“Efficient Mosquito Coil Packaging Line: Advanced Pillow Bag & Cartoning Machine for Seamless Coil Packing”