Coil Packing Line: Enhancing Efficiency and Safety in Copper Coil Handling

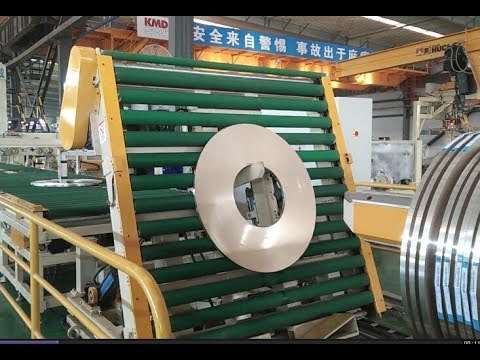

The coil packing system has revolutionized the way copper coils are handled and packed, offering a seamless and efficient solution for various industries. This article delves into the world of coil packing, exploring the benefits and features of the automatic slitted copper coil and copper belt packing line.

In today's fast-paced and demanding industrial landscape, maximizing efficiency and ensuring safety are paramount. This is where the coil packing line comes into play. Designed specifically for handling and packing copper coils, this innovative system streamlines the entire process, enhancing productivity and reducing the risk of damage to the coils.

The automatic slitted copper coil and copper belt packing line from Fhopepack is a game-changer in the industry. Its advanced features and cutting-edge technology make it a must-have for businesses dealing with copper coils. With a focus on safety, efficiency, and convenience, this packing line ensures that coils are handled and packed with utmost care.

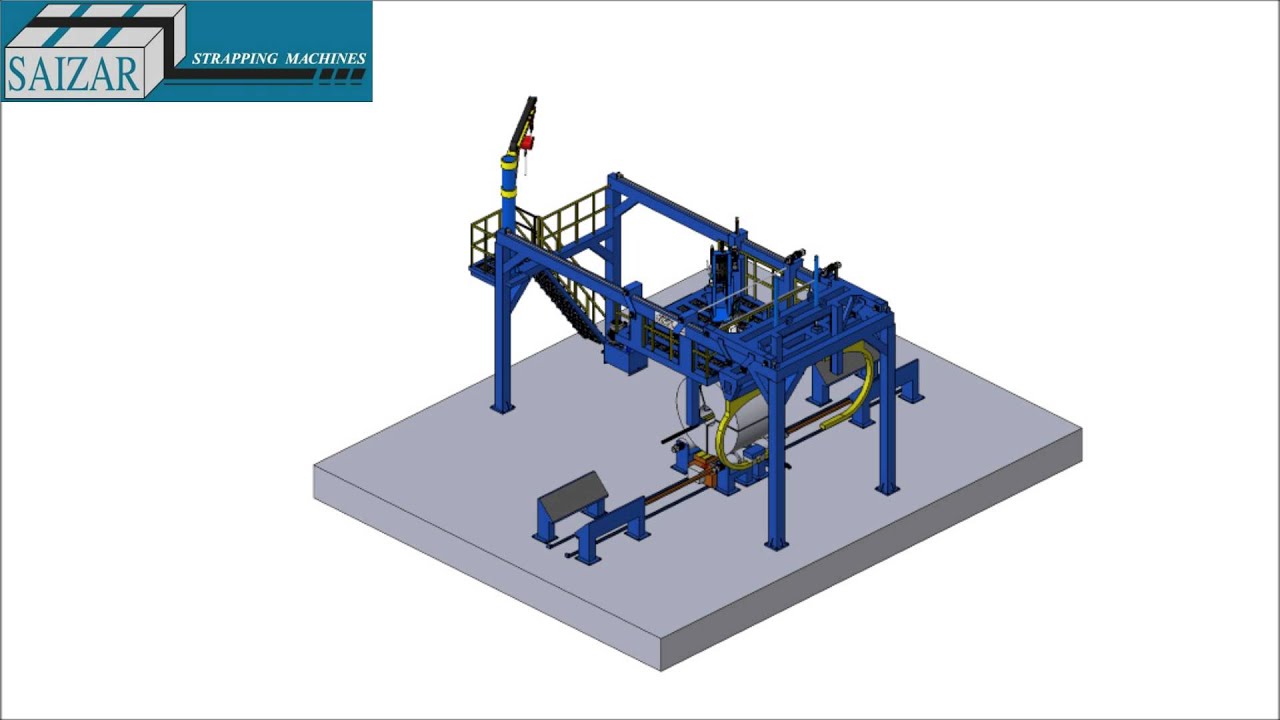

One of the standout features of this coil packing line is its automation capabilities. By eliminating manual labor and human error, the system significantly reduces the risk of accidents and damage to the coils. The automation also allows for faster and more precise packing, thereby increasing overall productivity.

In addition to automation, the coil packing line also offers customization options. This means that businesses can tailor the system to their specific needs and requirements. Whether it's adjusting the packing speed or incorporating additional safety features, Fhopepack ensures that every client gets a coil packing line that perfectly suits their operations.

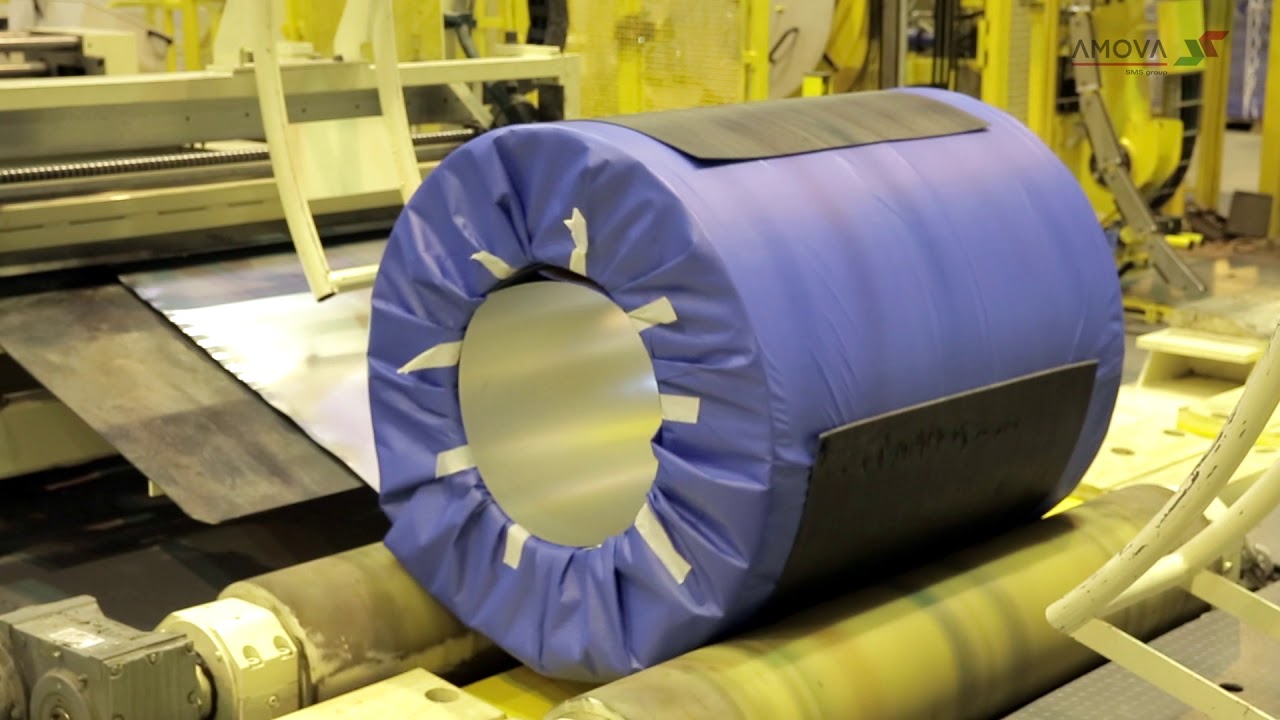

Safety is a top priority when it comes to handling copper coils. The automatic slitted copper coil and copper belt packing line addresses this concern by incorporating various safety features. From sensors that detect abnormalities in the packing process to protective barriers that prevent accidents, this system goes above and beyond to ensure the well-being of both workers and the coils themselves.

Efficiency is another crucial aspect of the coil packing line. By automating the packing process, businesses can save time and resources. The system's fast packing speed and precise coil positioning contribute to increased efficiency, allowing companies to meet tight deadlines and maximize their output.

Moreover, the coil packing line is designed to accommodate different coil sizes and shapes. This versatility makes it suitable for a wide range of industries, from electrical and automotive to HVAC and construction. Whether it's large copper coils or smaller slitted coils, this packing line can handle them all with ease.

The benefits of the coil packing line extend beyond efficiency and safety. By reducing the risk of damage to the coils, businesses can save on costly repairs or replacements. Additionally, the system's compact design ensures optimal use of space, making it ideal for companies with limited floor area.

In conclusion, the coil packing line has revolutionized the way copper coils are handled and packed. With its advanced automation features, customization options, and focus on safety and efficiency, this system is a game-changer for industries that heavily rely on copper coils. By investing in the automatic slitted copper coil and copper belt packing line from Fhopepack, businesses can streamline their operations, increase productivity, and ensure the well-being of their workers.

coil packing line

"Efficient Packaging Solutions for Copper Coils and Belts: Streamlining Production with Automated Packing Lines"