The Revolution of Coil Packing Line: Automating the Wire Coil Handling Process

In today’s fast-paced industrial world, efficiency is paramount. Companies are constantly seeking ways to streamline their operations and reduce manual labor. One such innovation that has taken the manufacturing industry by storm is the automatic wire coil packing line. This cutting-edge technology has revolutionized the way wire coils are handled, lifted, and packed, eliminating the need for manual intervention and significantly improving productivity. Let us delve into this remarkable development and explore the benefits it brings to the table.

The coil packing line is a game-changer, particularly for industries that deal with wire coils on a regular basis. In the past, workers had to manually handle, lift, and pack these coils, which was not only time-consuming but also labor-intensive. The introduction of the automatic wire coil packing line has transformed this process, making it faster, more efficient, and less physically demanding.

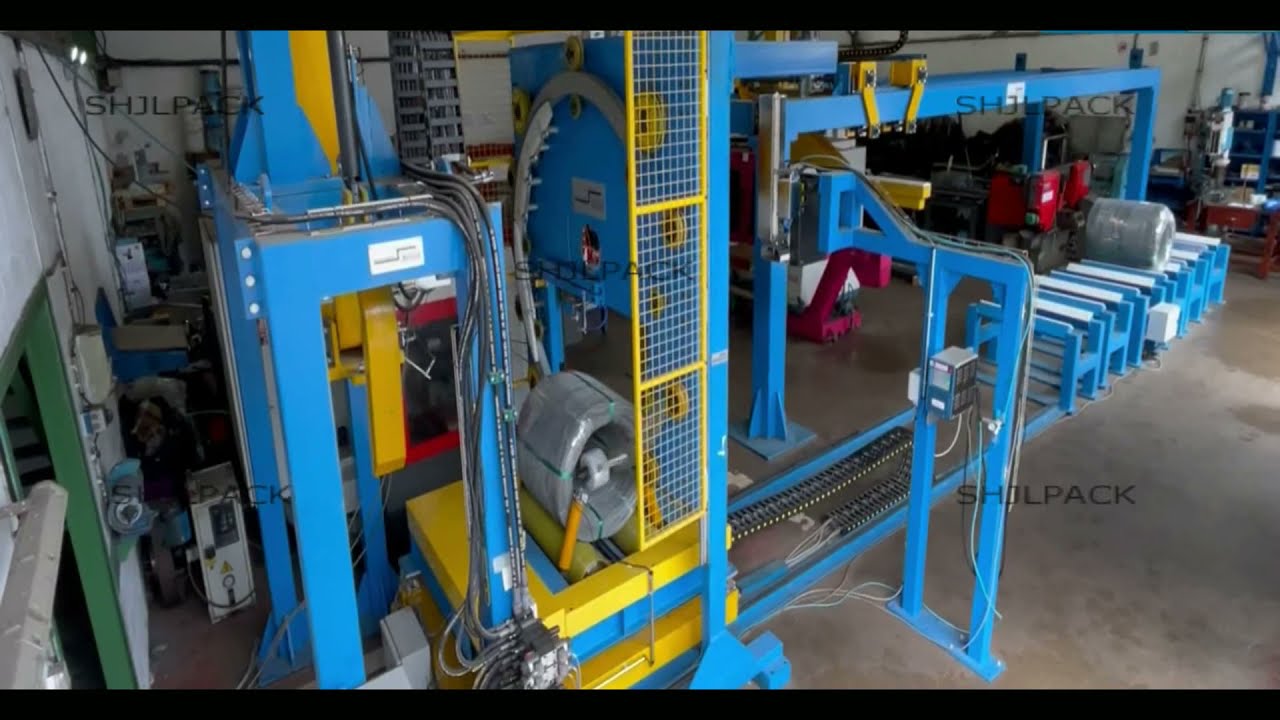

By incorporating a storage station into the packing line, the need for manual packing is completely eliminated. This means that workers no longer have to spend hours wrapping, strapping, and securing the coils. Instead, the automated system takes care of the entire process, from handling the coils to packaging them securely. This not only reduces the risk of injury to workers but also frees up valuable time that can be utilized for other tasks, ultimately boosting overall productivity.

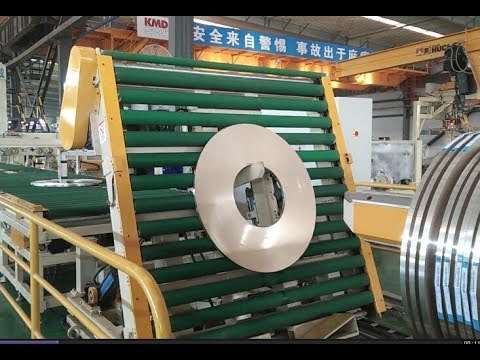

The coil packing line operates seamlessly, ensuring that the coils are handled with utmost care. The system uses state-of-the-art technology to lift the coils, minimizing the risk of damage or deformation. This is crucial, as wire coils are often used in industries where precision and quality are of utmost importance, such as automotive, construction, and manufacturing. The automatic handling and lifting mechanism ensures that the coils are positioned correctly and that their integrity remains intact throughout the packing process.

Furthermore, the coil packing line is designed to accommodate various coil sizes, making it highly versatile. Whether dealing with small or large coils, the system can easily adjust to meet the specific requirements. This flexibility is invaluable, as it allows companies to pack a wide range of wire coils without the need for additional equipment or modifications. The ability to handle different coil sizes efficiently is a testament to the ingenuity of this technology.

In addition to its efficiency and versatility, the automatic wire coil packing line also offers significant cost savings. By eliminating the need for manual labor, companies can reduce their workforce and allocate resources to other areas of their operations. The system is designed to operate with minimal supervision, further reducing labor costs. Additionally, the automated process ensures consistent and uniform packing, minimizing material waste and unnecessary expenses.

The benefits of the coil packing line extend beyond the immediate advantages for companies. With the automation of this process, workers are freed from repetitive and physically demanding tasks, allowing them to focus on more skilled and fulfilling responsibilities. This not only improves job satisfaction but also promotes a safer working environment, reducing the risk of work-related injuries.

As technology continues to advance, it is no surprise that industries are embracing automation to enhance efficiency and productivity. The coil packing line represents a significant leap forward in the wire coil handling process, offering a range of benefits that were unimaginable just a few years ago. With its ability to handle, lift, and pack wire coils automatically, this cutting-edge technology has transformed the manufacturing landscape, making it faster, safer, and more cost-effective.

In conclusion, the introduction of the automatic wire coil packing line has revolutionized the way wire coils are handled, lifted, and packed. This innovative technology has eliminated the need for manual packing, significantly improving efficiency and productivity. With its state-of-the-art handling and lifting mechanisms, the system ensures the coils are handled with precision and care, minimizing the risk of damage. Moreover, the versatility of the system allows for the handling of various coil sizes, making it adaptable to different industry needs. The cost savings and improved working conditions further highlight the advantages of this remarkable technology. As the manufacturing industry continues to evolve, the coil packing line stands at the forefront of automation, setting new standards for efficiency and productivity.

coil packing line

“Efficient and Automated Wire Coil Packing Line: Streamlining Packaging Processes for Enhanced Productivity”