Automatic Coil Packing Line: Revolutionizing the Packaging Industry

In today’s fast-paced world, efficiency and productivity are key factors in the success of any industry. One such industry that heavily relies on these factors is the packaging industry. With the increasing demand for packaged goods, manufacturers are constantly seeking innovative solutions to streamline their packaging processes and meet market demands. One such solution that has gained significant attention is the automatic coil packing line.

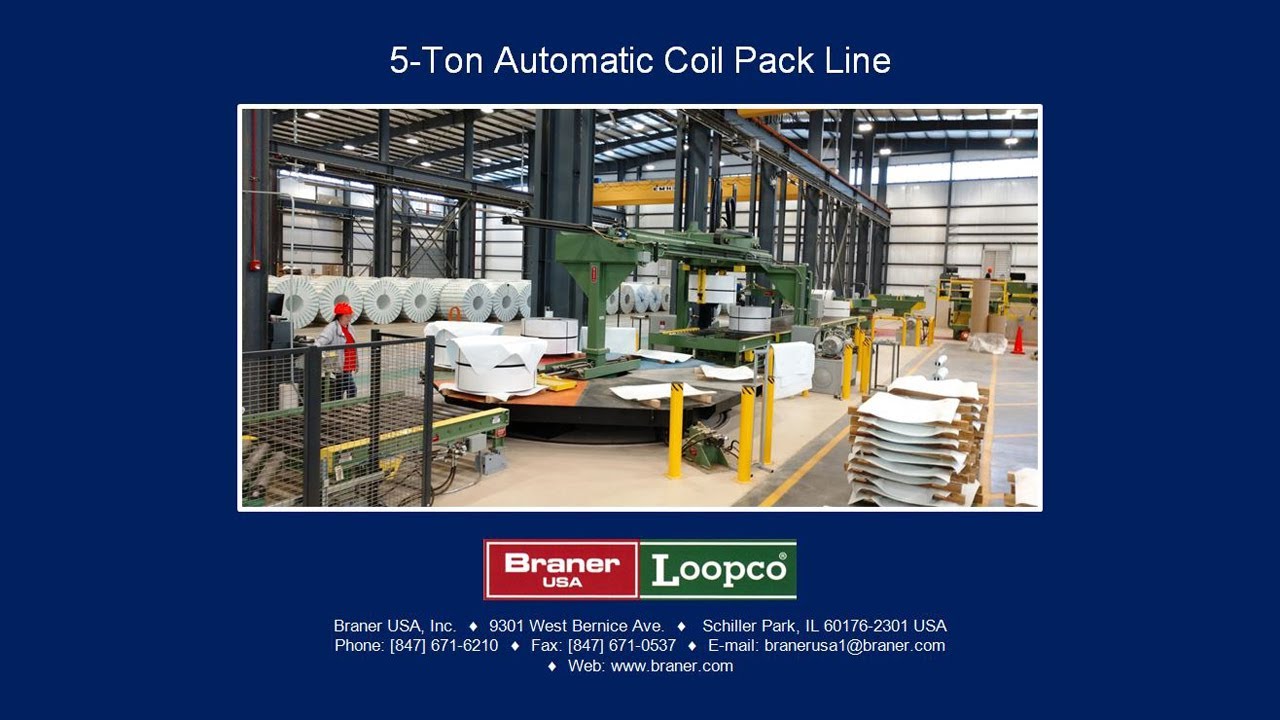

The automatic coil packing line is a game-changer in the packaging industry. It combines the power of automation with advanced technology to provide a seamless and efficient packaging solution for coils. This revolutionary system not only saves time but also reduces labor costs and ensures optimum packaging quality.

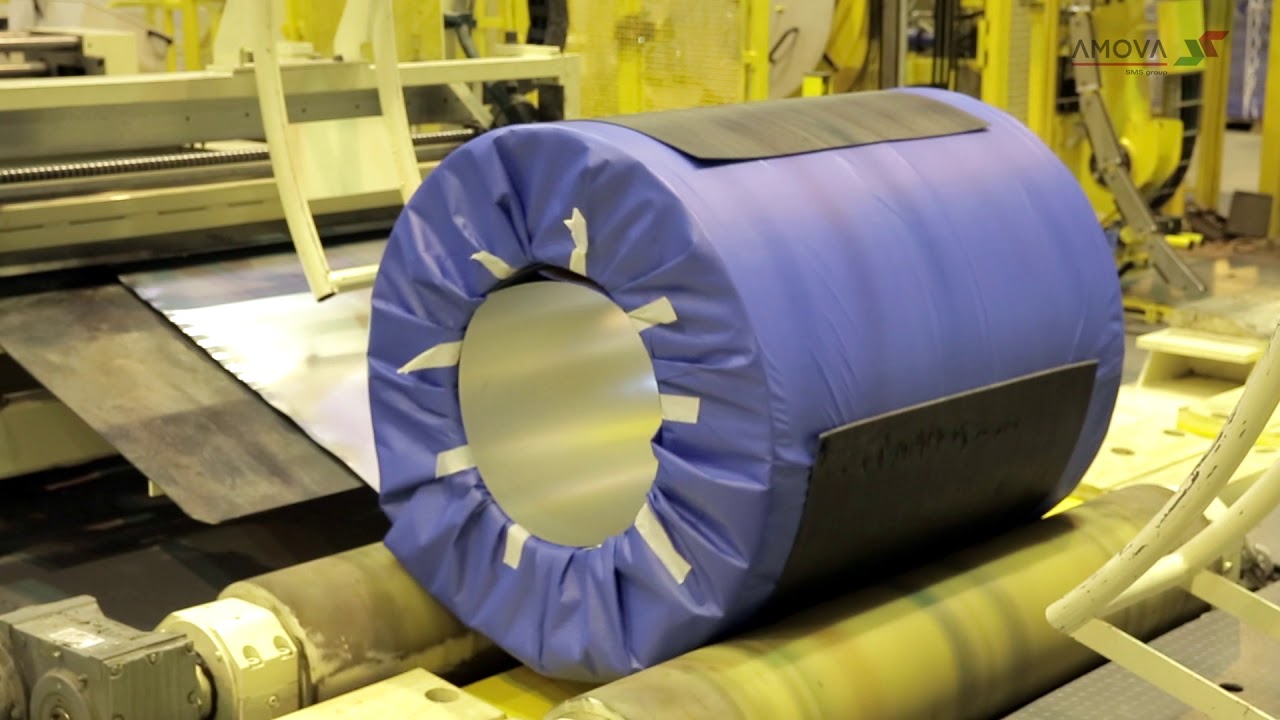

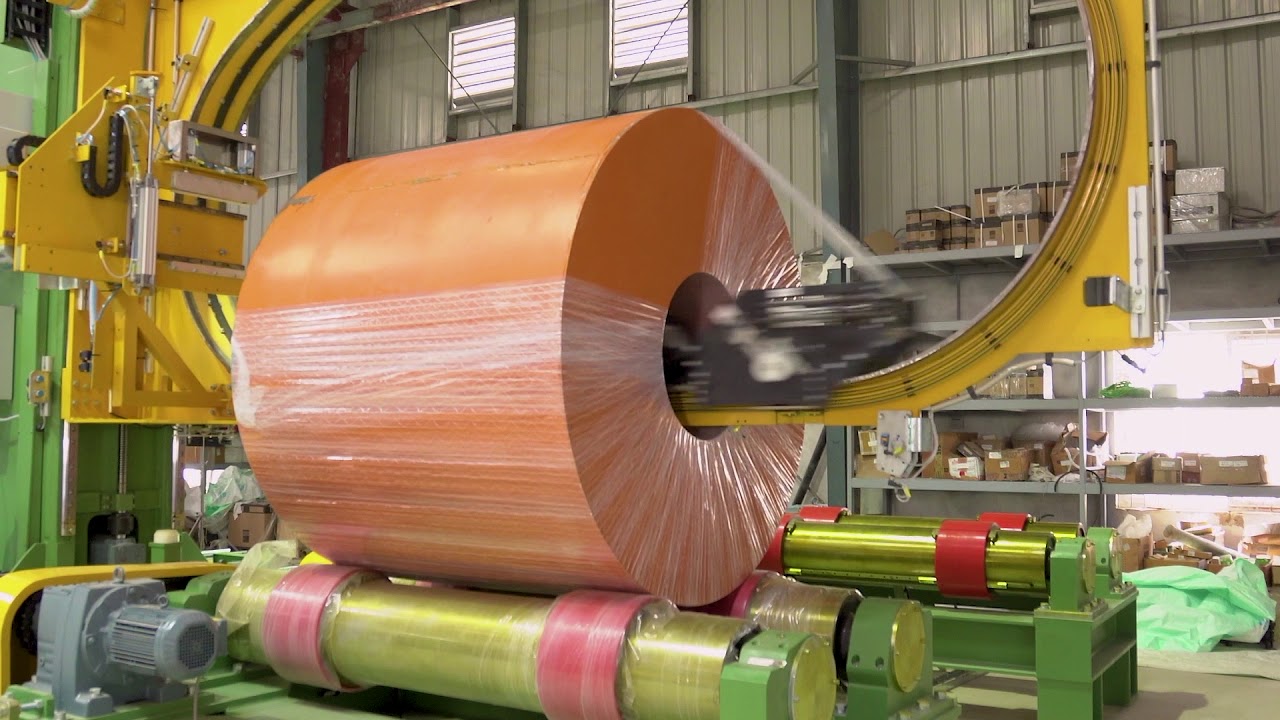

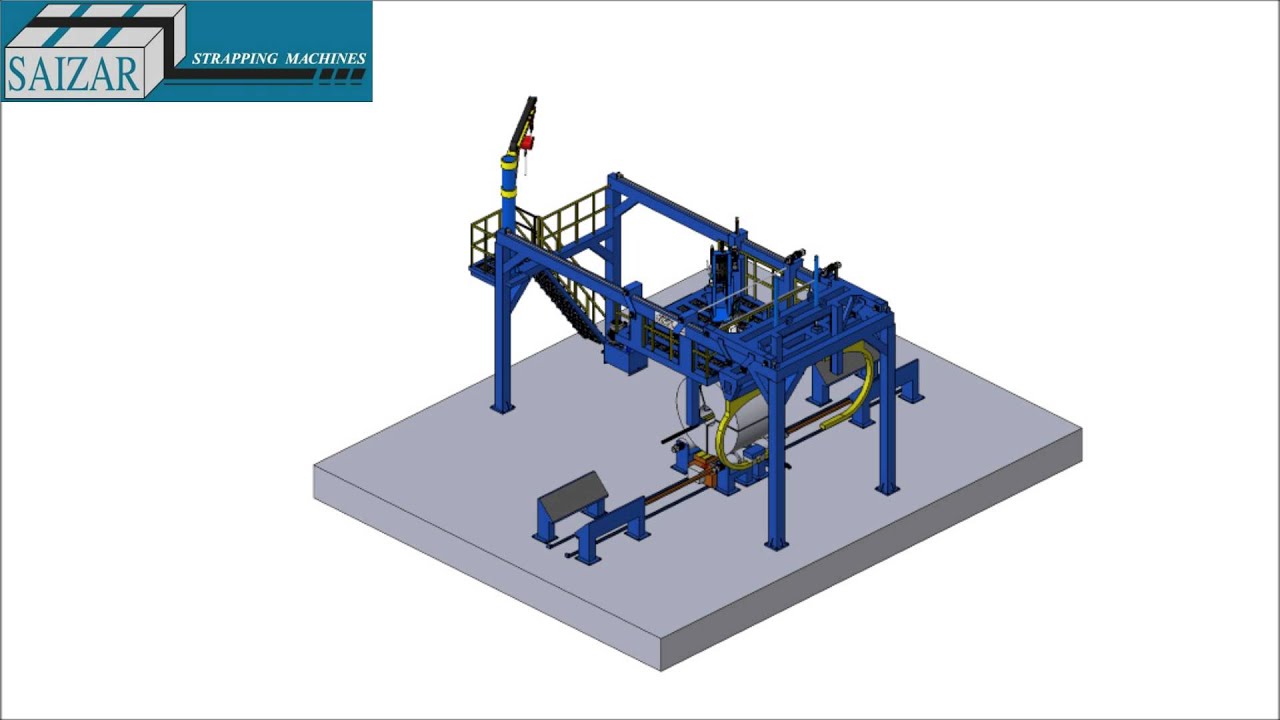

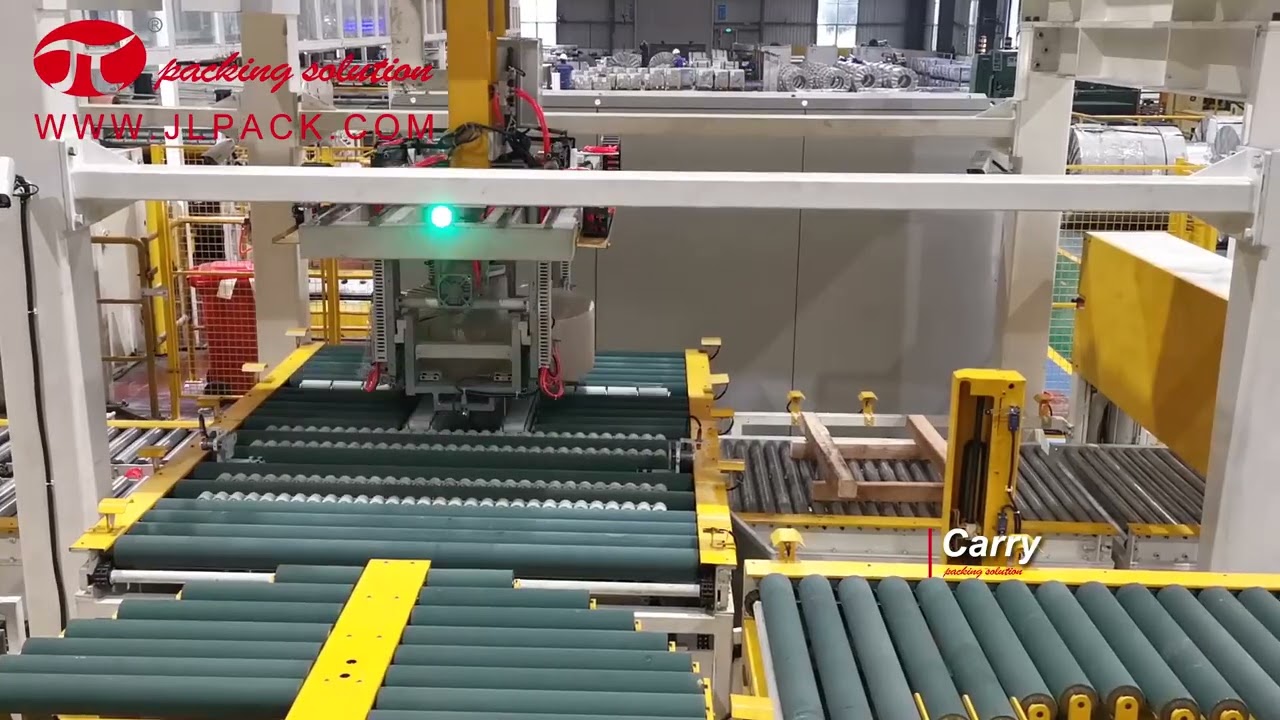

At the heart of the automatic coil packing line is the coil strapping and palletizing system. This system effectively secures coils with straps, preventing any damage during transportation and storage. The strapping process is fully automated, eliminating the need for manual labor and reducing the risk of human error. Additionally, the system is equipped with sensors and advanced algorithms that ensure the straps are applied with the perfect tension, further enhancing the packaging quality.

The timber used in the palletizing system plays a crucial role in maintaining the integrity of the packaged coils. With its robust and durable nature, timber provides a strong and stable base for the coils, ensuring they remain intact during handling and transportation. The automated palletizing system precisely stacks the coils on the timber pallets, maximizing space utilization and minimizing the risk of damage.

The benefits of the automatic coil packing line are not limited to efficiency and productivity improvements. This cutting-edge technology also offers enhanced safety features to protect both the workers and the packaged coils. With the automated strapping and palletizing system, the risk of injuries associated with manual handling is significantly reduced. Moreover, the secure packaging provided by the system prevents any damage to the coils, ensuring they reach their destination in perfect condition.

The coil packing line has garnered attention from various industry players, ranging from manufacturers to distributors. Its ability to handle a wide range of coil sizes and types makes it a versatile solution for different industries, including steel, aluminum, and automotive. Moreover, the system can be easily integrated into existing production lines, minimizing downtime and maximizing efficiency.

As a third party witnessing the impact of the automatic coil packing line, it is evident that this technology is revolutionizing the packaging industry. The combination of automation, advanced technology, and robust packaging materials has paved the way for a new era in coil packaging. Manufacturers can now meet market demands with ease, while ensuring the safety and integrity of their products.

The coil packing line has also caught the attention of industry magazines, with many praising its efficiency and transformative capabilities. Magazine editors have highlighted the positive impact this technology has had on the packaging industry, predicting a bright future for automated packaging systems.

In conclusion, the automatic coil packing line with coil strapping and palletizing system is a game-changer in the packaging industry. Its ability to automate the packaging process, ensure packaging quality, and enhance worker safety has made it a preferred choice for manufacturers across various industries. With its versatility and efficiency, this technology is set to redefine the packaging industry and meet the ever-growing demands of the market.

coil packing line

“Efficient Coil Packing Line: Streamlined Slitting, Strapping, and Palletizing System”