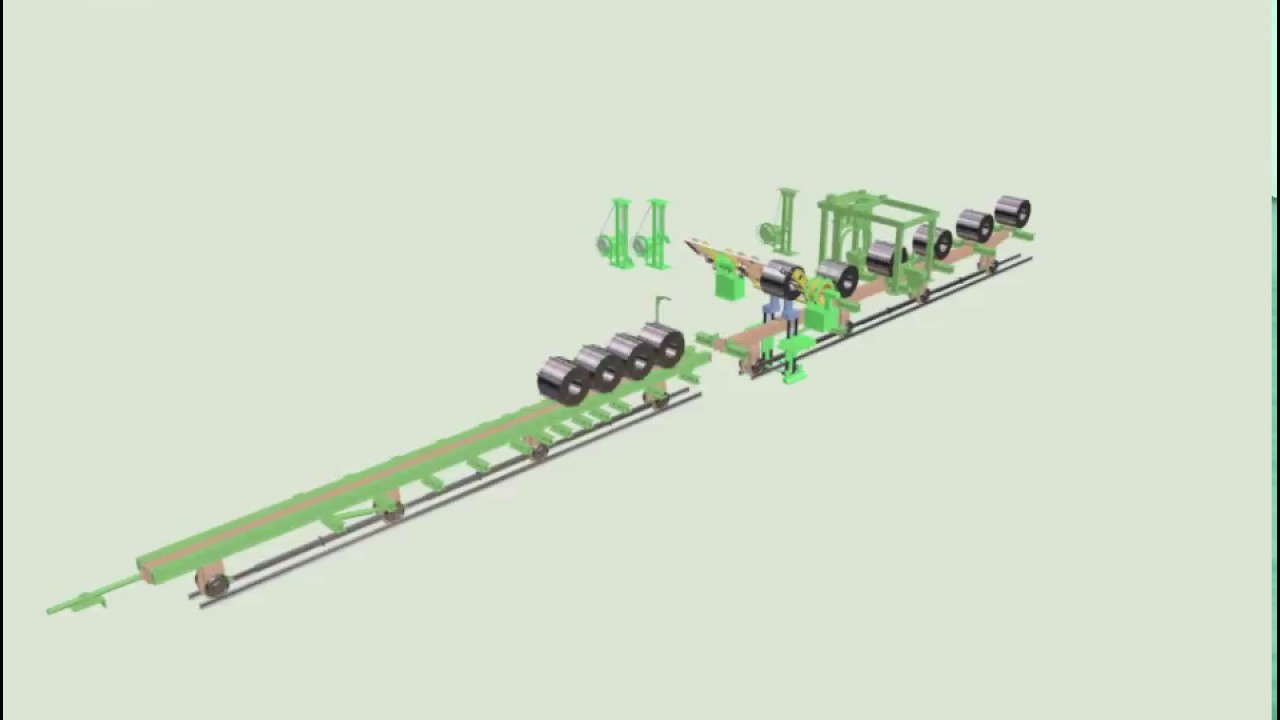

Automatic Steel Coil Packing Line for Circumferential or Radial Binding

Steel coil packing plays a crucial role in ensuring the safe and secure transportation of steel coils. Efficient packing not only prevents damage to the coils but also saves time and resources during handling and storage. In this article, we will explore the benefits and features of an automatic steel coil packing line designed for circumferential or radial binding.

The automatic steel coil packing line is a revolutionary solution in the industry, offering a comprehensive and efficient way to pack steel coils. With advanced technology and intelligent features, this equipment streamlines the entire packing process, ensuring optimal results with minimal effort.

One of the key advantages of this packing line is its ability to handle both circumferential and radial binding. This means that it can adapt to different coil shapes and sizes, providing versatility for various packaging requirements. Whether you need to pack round coils, square coils, or irregularly shaped coils, this equipment can handle it all.

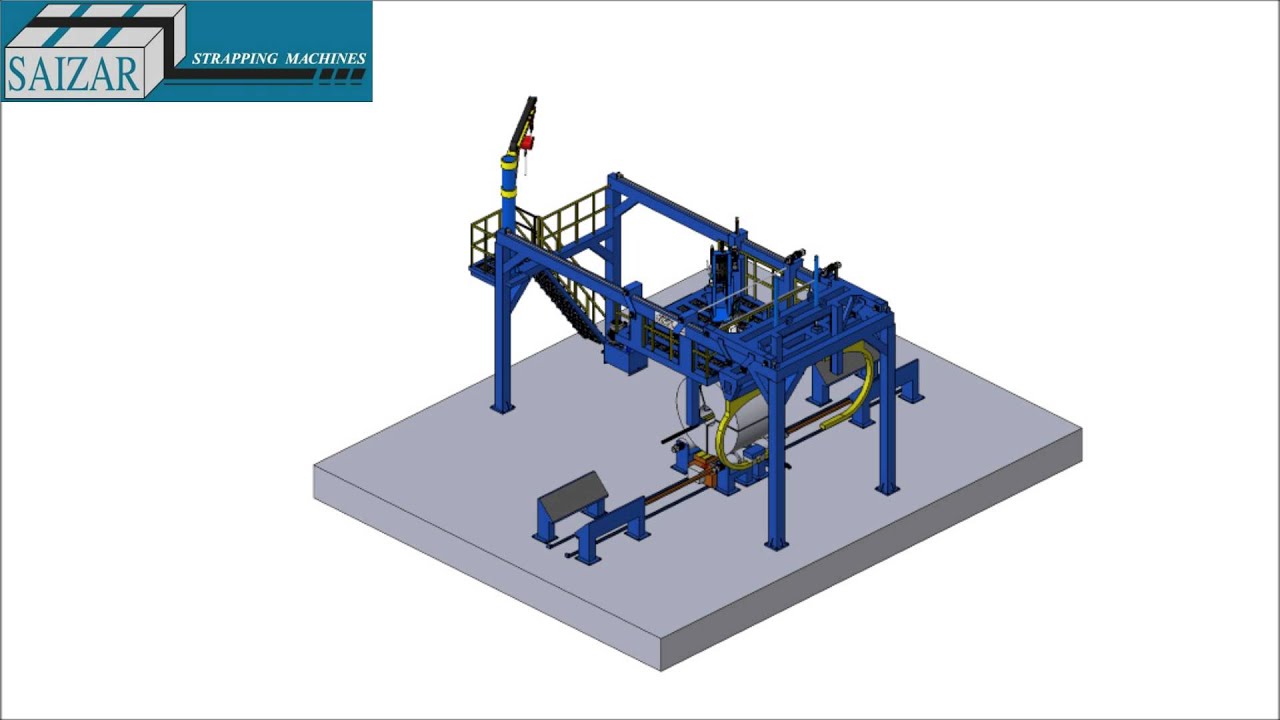

The packing line utilizes cutting-edge automation technology, reducing the need for manual intervention. This not only increases productivity but also minimizes the risk of human errors. The system can be easily programmed to adjust parameters such as wrapping speed, tension control, and film overlap, ensuring consistent and secure packaging every time.

To further enhance efficiency, the automatic steel coil packing line incorporates state-of-the-art sensors and control systems. These enable real-time monitoring of the packing process, allowing for immediate adjustments if any issues arise. The system can detect abnormalities such as film breakage, insufficient tension, or misalignment, ensuring that the coils are packed correctly and securely.

Another noteworthy feature of this packing line is its high-speed operation. With rapid wrapping and binding capabilities, it significantly reduces packing time and boosts overall productivity. This is particularly advantageous for industries that deal with large volumes of steel coils, as it enables faster turnaround times and increased output.

Furthermore, the automatic steel coil packing line offers excellent film utilization, minimizing waste and reducing packaging costs. The system optimizes the film stretch ratio, ensuring that the right amount of film is used for each coil. This not only saves resources but also promotes environmental sustainability.

In terms of safety, this packing line is designed with utmost consideration. It includes various safety features such as emergency stop buttons, protective barriers, and interlocking systems. These measures protect operators from potential hazards and ensure a secure working environment.

Additionally, the automatic steel coil packing line is user-friendly and easy to operate. It features a user-friendly interface with intuitive controls, allowing operators to quickly understand and navigate the system. Training requirements are minimal, enabling smooth integration into existing production lines.

In conclusion, the automatic steel coil packing line for circumferential or radial binding offers a comprehensive and efficient solution for the packaging of steel coils. With its advanced technology, intelligent features, and high-speed operation, it maximizes productivity while ensuring the safety and security of the coils. Moreover, its versatility, film utilization optimization, and user-friendly interface make it a valuable asset for industries dealing with steel coil packing. Invest in this innovative equipment to streamline your packing process and elevate your operations to new heights.

For more information and to explore the wide range of automatic steel coil packing line equipment available, please visit [website].

coil packing line

“Efficient Steel Coil Packing Line: Optimal Binding for Circumferential or Radial Packaging”