The Unique Coil Packing System for Your Slitting Line

In the fast-paced world of industrial manufacturing, efficiency and productivity are key factors for success. Companies are constantly searching for innovative solutions to streamline their processes and maximize output. One such solution that has been gaining traction in recent years is the coil packing line. This state-of-the-art system offers a unique and efficient way to package steel coils, saving time, reducing labor costs, and ensuring the safety of the products.

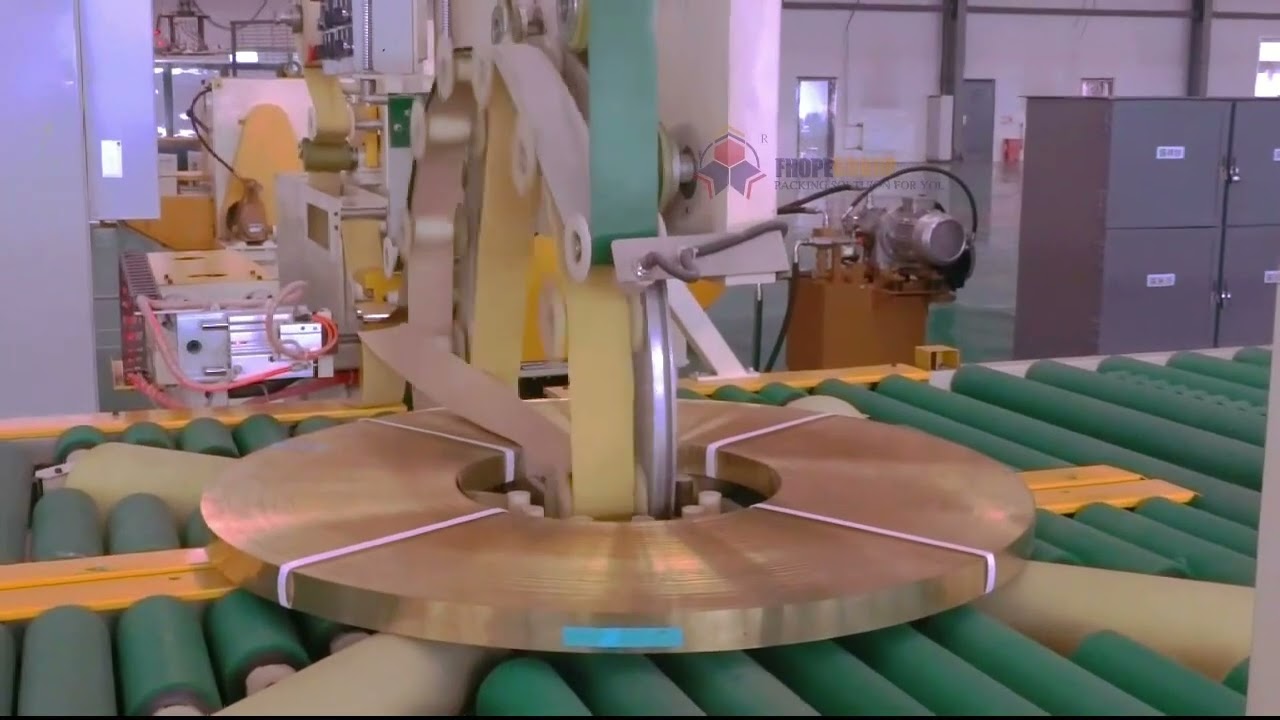

The coil packing line is an integral part of the slitting process. It involves the packaging of steel coils, which are then transported to their final destination. The process starts with the coil turnstile, a crucial component of the system. This turnstile acts as a bridge between the slitting line and the packing line, ensuring a smooth transition from one process to the other.

The coil turnstile is designed to handle large volumes of coils with ease. It can accommodate different sizes and weights, making it a versatile solution for various manufacturing requirements. With its robust construction and advanced control system, the turnstile ensures the safe and efficient handling of coils, minimizing the risk of damage or accidents.

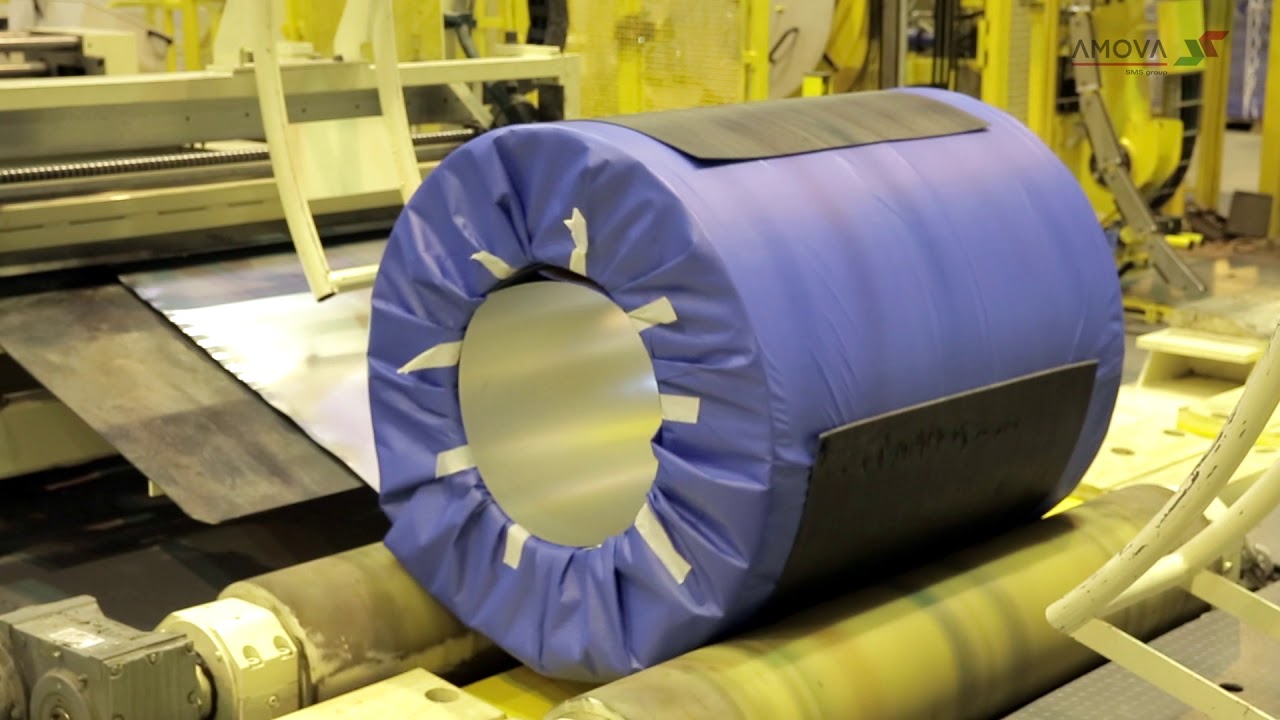

Once the coils are loaded onto the turnstile, they are transported to the packing area. This is where the magic happens. The automatic steel coil packaging line takes over, wrapping the coils in a protective layer and securing them for transportation. This packaging process is highly efficient and can be customized to meet specific requirements.

The coil packing line utilizes advanced technology to ensure the highest level of precision and accuracy. It is equipped with sensors and control systems that monitor the entire process, from loading to packaging. This ensures that each coil is packaged correctly and securely, eliminating the risk of damage during transportation.

One of the key advantages of the coil packing line is its ability to handle a wide range of coil sizes and weights. Whether you’re dealing with small coils or large ones, this system can handle them all. This versatility is a major advantage for manufacturers who deal with different types of steel coils on a regular basis.

Another advantage of the coil packing line is its speed. Traditional packaging methods can be time-consuming and labor-intensive. With the automatic steel coil packaging line, the entire process is automated, significantly reducing the time and effort required. This allows manufacturers to increase their productivity and meet tight deadlines without compromising on quality.

The coil packing line also offers significant cost savings. By automating the packaging process, manufacturers can reduce the need for manual labor, saving on labor costs. Additionally, the precise packaging provided by the system reduces the risk of damage during transportation, minimizing the need for costly repairs or replacements.

In conclusion, the coil packing line is a game-changer for the manufacturing industry. Its unique features and advanced technology make it an ideal solution for companies looking to streamline their operations and maximize productivity. With its versatility, efficiency, and cost-effectiveness, the coil packing line is a must-have for any manufacturer dealing with steel coils.

If you’re in the market for a coil packing system, be sure to explore the options available. Look for a provider that offers a comprehensive range of solutions and has a proven track record in the industry. With the right coil packing line, you can take your manufacturing processes to the next level and stay ahead of the competition.

Remember, efficiency and productivity are the keys to success in today’s fast-paced manufacturing world. Invest in the coil packing line and watch your operations soar to new heights.

coil packing line

“Efficient Steel Coil Packaging and Handling Solutions: Streamlining Production with Automated Systems”