The Importance of Mosquito Coil Packing Line in Mosquito Control

Mosquitoes are one of the most annoying and dangerous insects on the planet. Not only do they cause irritation with their incessant buzzing and itchy bites, but they also transmit deadly diseases such as malaria, dengue fever, and Zika virus. As a result, mosquito control is of utmost importance in order to protect public health.

In recent years, the use of mosquito coils has become a popular method for repelling mosquitoes. These coils, when lit, release a smoke that contains insecticides, effectively driving away mosquitoes and other flying insects. However, the production and packaging of mosquito coils can be a complex and time-consuming process. That’s where the Mosquito Coil Packing Line comes into play.

The Mosquito Coil Packing Line is a complete production line that includes various machines designed to streamline the production and packaging of mosquito coils. As a professional mosquito coil machine manufacturer in China, we are proud to offer a comprehensive range of machines that can take you from the initial mixing of ingredients to the final packaging of the coils.

Let’s take a closer look at the key machines that make up our Mosquito Coil Packing Line:

1. Mosquito Coil Mixing Machine: This machine is responsible for thoroughly mixing the ingredients that make up the mosquito coil, including the active insecticide, binders, and fillers. It ensures that the mixture is evenly distributed, resulting in high-quality coils.

2. Mosquito Coil Forming Machine: Once the mixture is ready, it needs to be shaped into coils. The Mosquito Coil Forming Machine takes care of this task by pressing the mixture into the desired coil shape. It ensures consistency in size and shape, which is crucial for the effectiveness of the coils.

3. Mosquito Coil Spraying Machine: After the coils are formed, they need to be sprayed with a special solution that enhances their insect-repellent properties. The Mosquito Coil Spraying Machine does this job efficiently, ensuring that every coil is adequately coated.

4. Mosquito Coil Drying Machine: The sprayed coils then need to be dried before they can be packaged. The Mosquito Coil Drying Machine uses a combination of heat and airflow to quickly and effectively dry the coils, allowing for faster production.

5. Mosquito Coil Folding Machine: Once the coils are dry, they need to be folded into a compact shape for easy packaging. The Mosquito Coil Folding Machine automates this process, folding the coils into the desired shape with precision and speed.

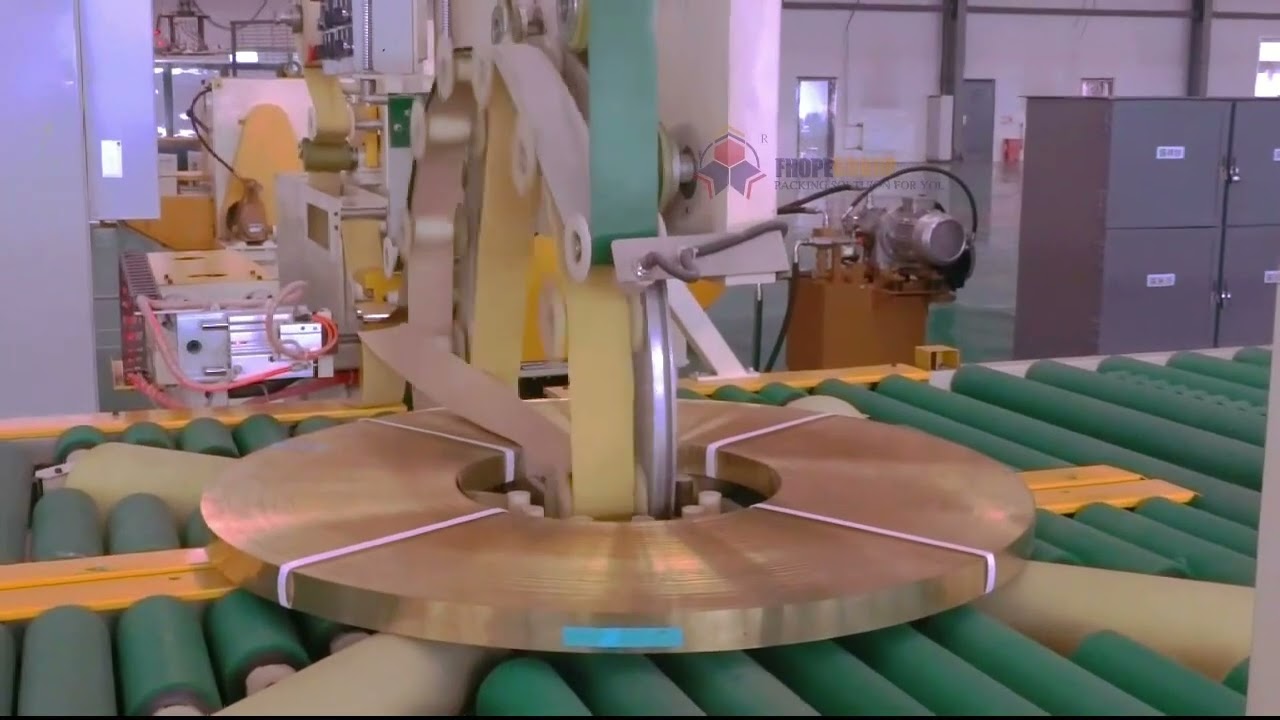

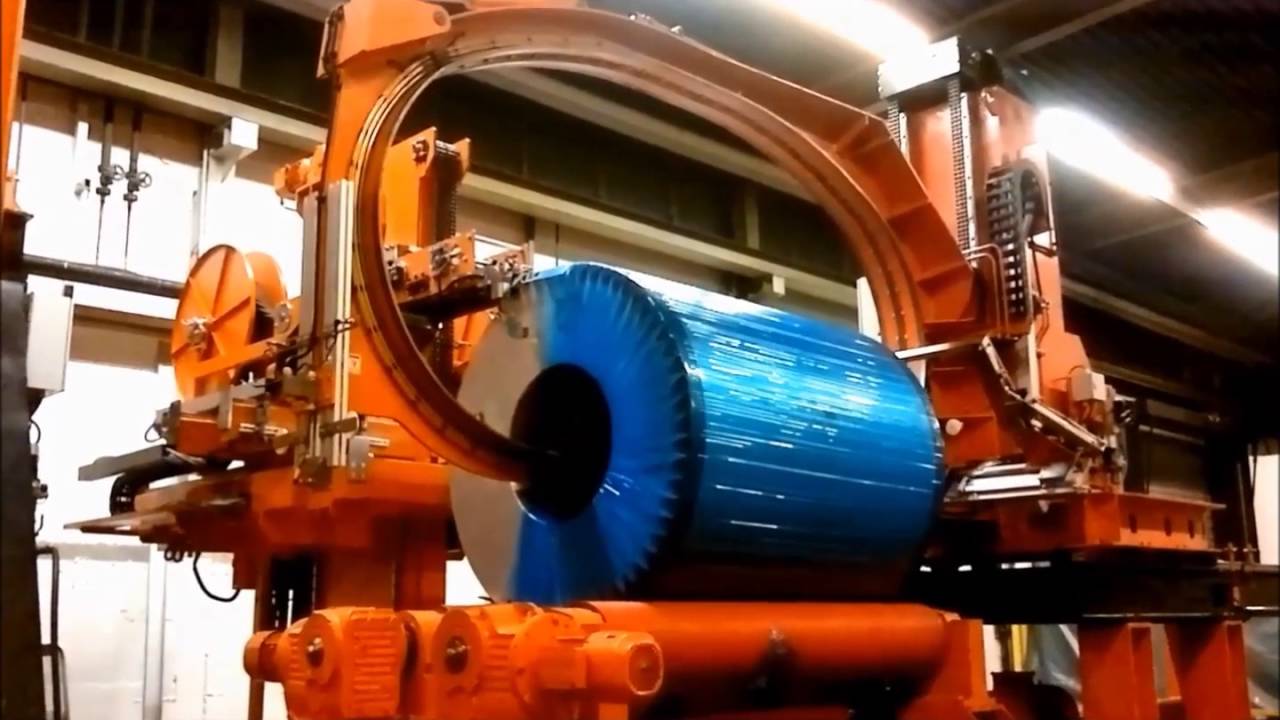

6. Mosquito Coil Packing Machine: Finally, the coils are ready to be packaged. The Mosquito Coil Packing Machine takes care of this task, wrapping the coils in protective packaging material and sealing them to ensure their freshness and effectiveness.

With our Mosquito Coil Packing Line, you can significantly increase your production efficiency and reduce labor costs. Furthermore, the automated nature of the machines ensures consistent quality control, resulting in high-quality mosquito coils that effectively repel mosquitoes and other flying insects.

In conclusion, the Mosquito Coil Packing Line plays a crucial role in the production and packaging of mosquito coils. By streamlining the process and automating key tasks, it allows for increased efficiency, reduced labor costs, and consistent quality control. If you are in the mosquito coil manufacturing business, investing in a Mosquito Coil Packing Line is a wise choice that will benefit both your business and public health.

So, why wait? Upgrade your mosquito coil production process with our state-of-the-art Mosquito Coil Packing Line and take a step towards a mosquito-free environment.

coil packing line

“Efficient and Automated Mosquito Coil Packaging, Folding, and Spraying Machines: Enhancing Mosquito Control with Advanced Technology”