Fan coil production, packaging, and installation services provided by YESNCER in various locations.

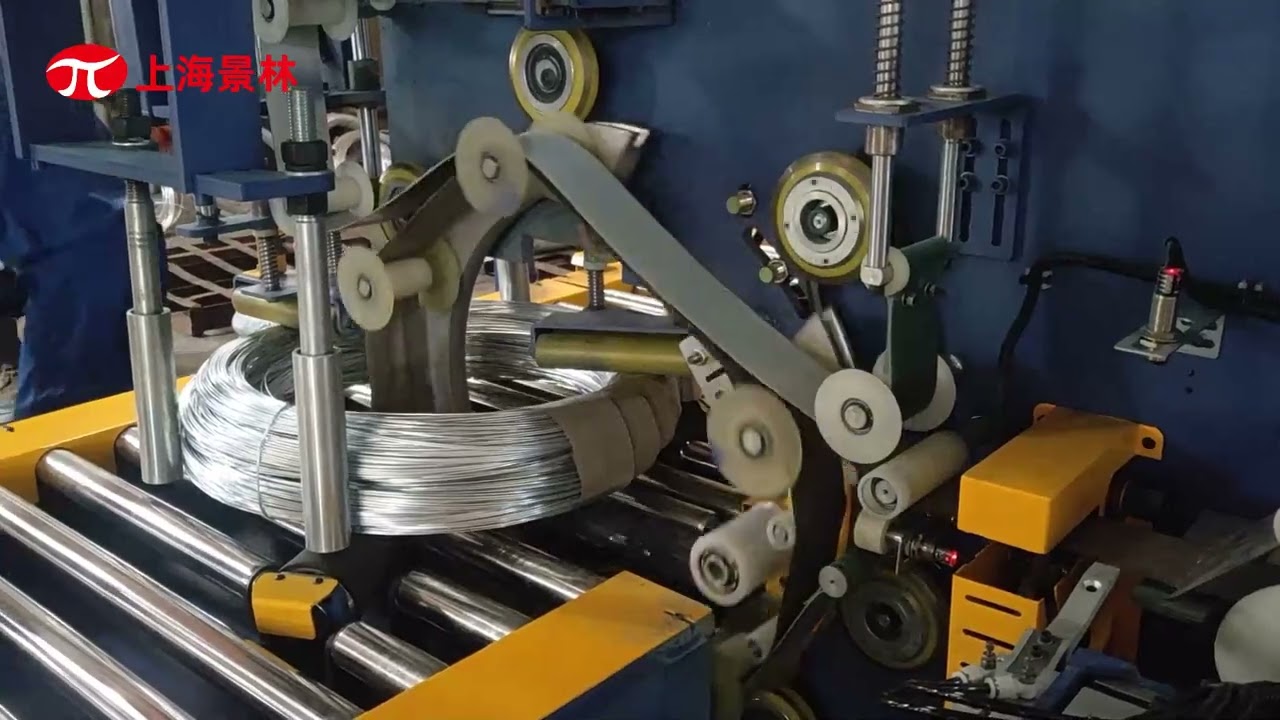

In today’s fast-paced world, the need for efficient and reliable refrigeration and heating systems has become paramount. Companies like Yuexin (Tianjin) Artificial Environment Engineering Technology Co., Ltd. have recognized this demand and are committed to providing top-notch solutions in this field. With their expertise and dedication, they have made a significant impact on the industry, […]