AUTOMATIC NARROW SLIT COIL PACKAGING LINE: A REVOLUTIONARY SOLUTION

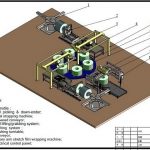

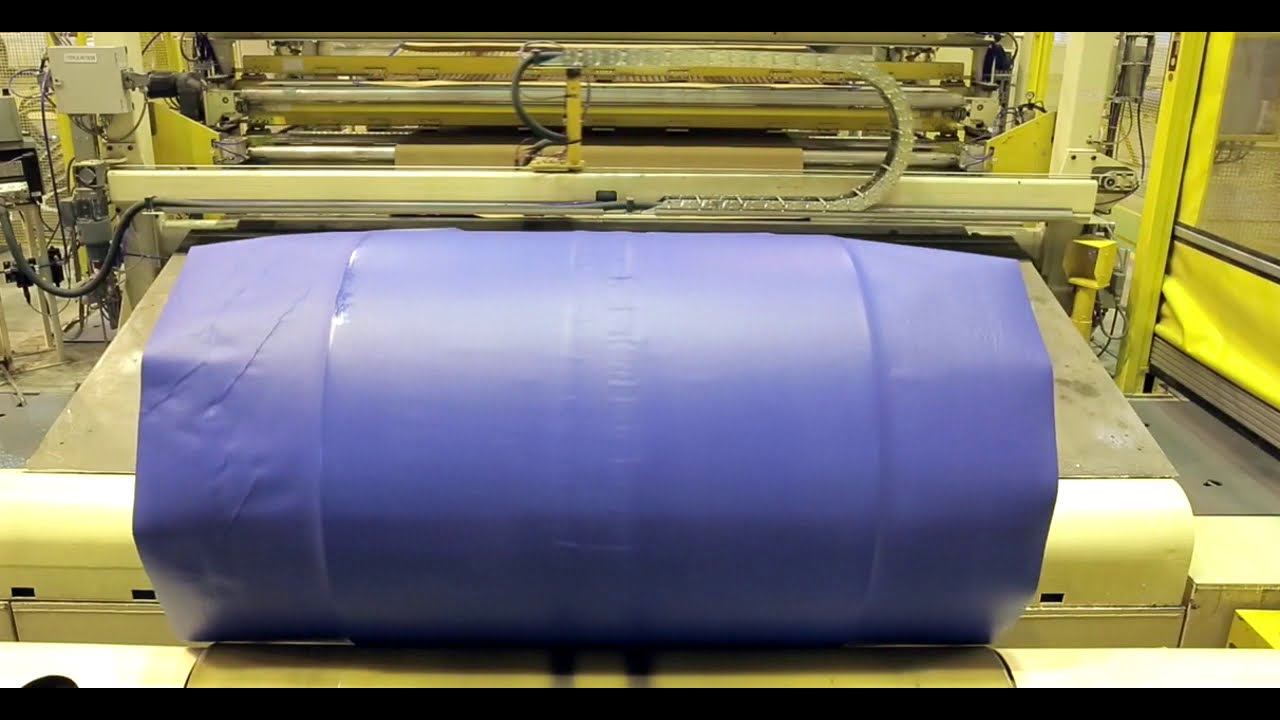

In today's fast-paced world, where efficiency and productivity are paramount, businesses across industries are constantly seeking innovative solutions to streamline their operations. One such breakthrough that has caught the attention of various sectors is the Automatic Narrow Slit Coil Packaging Line. This cutting-edge technology, developed by MVS ACMEI TECHNOLOGIES, has revolutionized the packaging process, offering wide expertise in consulting, detailing, designing, and supplying automatic packaging lines for coil products.

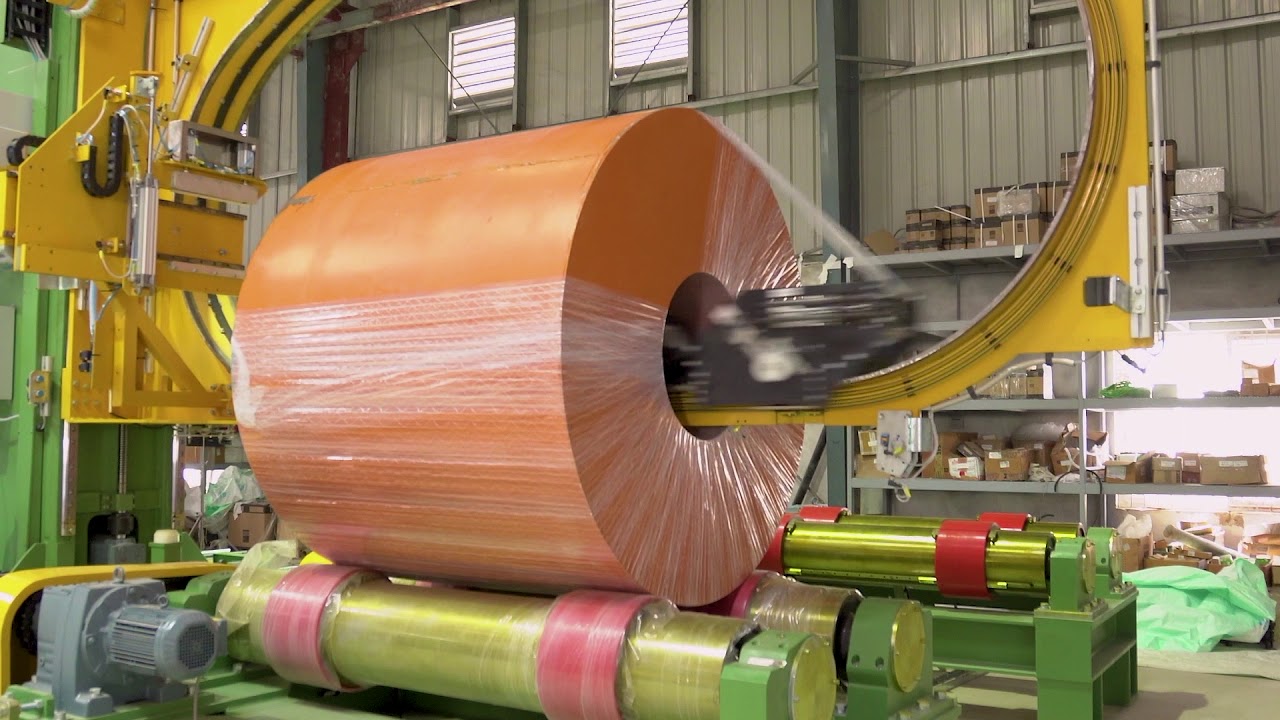

The coil packing line has become an integral component in industries that deal with narrow slit coils, as it provides a seamless packaging solution. This remarkable innovation has garnered significant attention from manufacturers, as it not only enhances productivity but also ensures the safety and protection of the coils during transportation and storage.

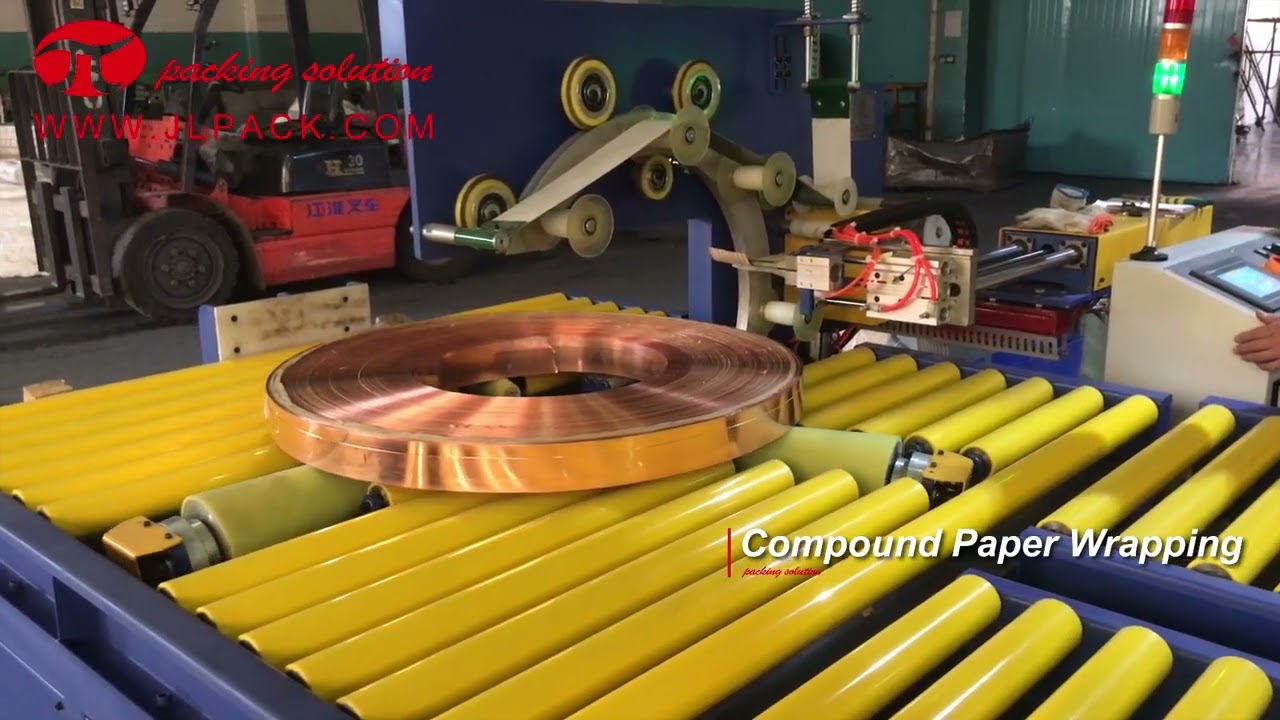

The Automatic Narrow Slit Coil Packaging Line offers a range of unparalleled features that set it apart from traditional packaging methods. With its state-of-the-art automation capabilities, this packaging line eliminates manual labor, reducing the risk of human error and increasing overall efficiency. The advanced technology incorporated in the system ensures precise and consistent packaging, guaranteeing the utmost quality for each coil.

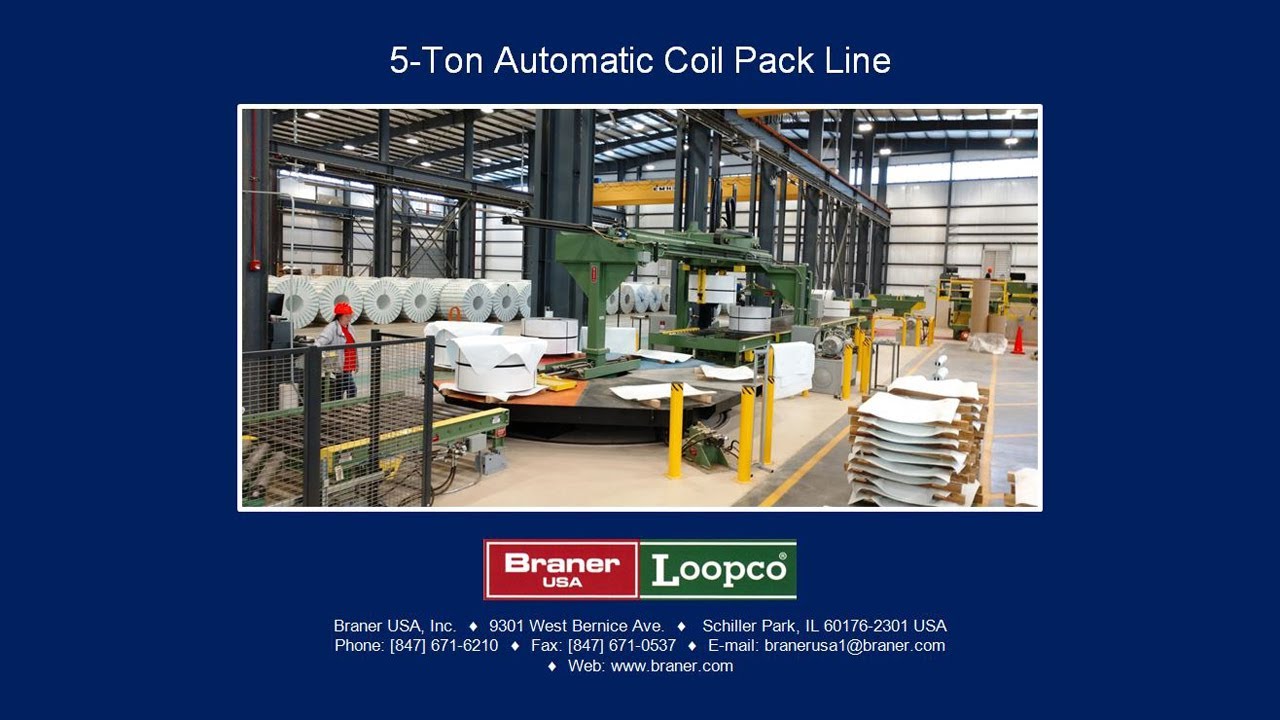

One of the key advantages of the Automatic Narrow Slit Coil Packaging Line is its versatility. It can accommodate various coil sizes and materials, making it suitable for a wide range of industries, including automotive, construction, and manufacturing. This flexibility allows businesses to adapt to changing market demands effortlessly.

To gain a deeper understanding of the impact of this technology, we spoke with industry experts who have implemented the Automatic Narrow Slit Coil Packaging Line in their operations. One such customer, a leading automotive manufacturer, shared their experience, stating, "Since integrating the coil packaging line into our production process, we have witnessed a significant increase in efficiency. The automated system has not only improved productivity but has also minimized wastage and reduced operational costs."

This sentiment was echoed by a technical engineer from another manufacturing company who stated, "The coil packaging line has transformed our operations. The precision and speed at which it operates have allowed us to meet tight deadlines without compromising on quality. Additionally, the system's user-friendly interface has made it easy for our staff to operate and maintain."

Furthermore, the Automatic Narrow Slit Coil Packaging Line has garnered praise for its focus on safety. The system incorporates various safety features, including sensors and alarms, to ensure the well-being of workers and prevent accidents. This commitment to safety aligns with industry standards and regulations, providing peace of mind to both manufacturers and employees.

Looking ahead, it is evident that the Automatic Narrow Slit Coil Packaging Line will continue to shape the future of packaging. With ongoing advancements in technology, this solution is expected to become even more efficient, further enhancing productivity and reducing environmental impact. As industries strive to meet ever-evolving market demands, the implementation of such innovative technologies will be crucial for their success.

In conclusion, the Automatic Narrow Slit Coil Packaging Line developed by MVS ACMEI TECHNOLOGIES has revolutionized the way industries package their narrow slit coils. With its advanced automation capabilities, versatility, and commitment to safety, this technology has proven to be a game-changer for businesses across various sectors. As we move forward, it is clear that this cutting-edge solution will continue to drive efficiency, productivity, and overall success in the ever-evolving world of packaging.

coil packing line

"Efficient and Streamlined Packaging Solutions for Automatic Narrow Slit Coil Packing Line: Enhancing Productivity and Quality"