Automatic Packing Solution for Wire Coil Packing: Enhancing Efficiency and Productivity

In today’s fast-paced world, where time is of the essence, every industry is constantly seeking ways to enhance efficiency and productivity. The wire coil packing industry is no exception. With the introduction of the coil packing line, businesses are experiencing a revolution in their packaging processes. This cutting-edge technology not only streamlines the packaging process but also ensures utmost precision and protection of wire coils during storage and transportation.

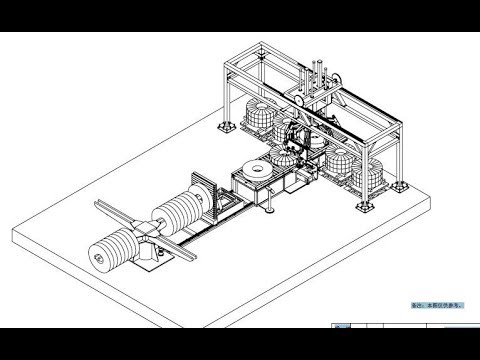

The coil packing line, a remarkable innovation in packaging technology, is transforming the wire coil packing process. This automated solution offers a seamless and efficient way of filling wire coils into bags, boxes, or pallets. The result is a secure and neatly packaged product ready for shipping or storage.

One of the key advantages of the coil packing line is its ability to optimize the packaging process. With its automated features, it eliminates the need for manual labor, thus reducing human error and increasing overall productivity. This technology is a game-changer for businesses that deal with large volumes of wire coils, as it can handle high-speed packaging with precision and consistency.

The coil packing line is designed to fulfill the specific needs of the wire coil industry. It offers customizable options for bagging, boxing, and palletizing, ensuring that each coil is packed securely according to the desired specifications. This level of customization allows businesses to meet the unique requirements of their customers, enhancing customer satisfaction and loyalty.

Moreover, the coil packing line is equipped with advanced technology that ensures the utmost protection of wire coils during the packaging process. The use of specialized materials and mechanisms prevents damage or deformation of the coils, reducing the risk of expensive losses. This level of protection is crucial, especially when dealing with delicate or high-value wire coils.

To better understand the impact of the coil packing line, let us delve into a case study. ABC Wire Coils, a leading player in the industry, recently adopted this automated solution to enhance their packaging processes. Prior to implementing the coil packing line, ABC Wire Coils relied on manual labor for packaging, which often resulted in inconsistencies and delays. However, after the installation of the coil packing line, the company witnessed a significant improvement in efficiency and productivity.

The coil packing line allowed ABC Wire Coils to package their products at a much faster pace, reducing the time required for packaging by 50%. This improvement not only saved valuable time but also optimized their resources, allowing them to allocate their workforce to other critical tasks. Additionally, the precision and consistency of the automated process ensured that each wire coil was packaged to perfection, eliminating the risk of damage during transportation.

The introduction of the coil packing line also had a positive impact on ABC Wire Coils’ bottom line. The reduction in manual labor costs, coupled with the increase in productivity, resulted in substantial cost savings for the company. Moreover, the enhanced packaging quality led to a decrease in customer complaints and returns, further boosting their reputation and customer satisfaction.

Looking ahead, the future of the wire coil packing industry seems promising with the continued advancements in technology. The coil packing line is just the beginning of a new era in packaging automation. As technology evolves, we can expect further innovations that will revolutionize the industry and take it to new heights.

In conclusion, the coil packing line has emerged as a game-changer in the wire coil packing industry. Its automated features, customizable options, and advanced technology have significantly enhanced efficiency, productivity, and product protection. Businesses that adopt this innovative solution can expect cost savings, improved customer satisfaction, and a competitive edge in the market. As the industry continues to evolve, embracing automation and technological advancements will be crucial for businesses to stay ahead of the curve.

coil packing line

“Efficient Wire Coil Packing Line: Streamlined Bagging, Boxing, Palletizing & Packing Process”