This is the machine for automatic feeding and paper/steel sheet for covering the cold roll steel coil on the surface. It is a remarkable piece of technology that has revolutionized the coil packing line industry. With its advanced features and efficient operation, this machine has become a game-changer in the packaging process.

The coil packing line is an essential part of the manufacturing industry, particularly in the steel sector. It involves the packaging of steel coils to protect them from damage during transportation and storage. Traditionally, this process was done manually, which was time-consuming and prone to human errors. However, with the introduction of the automatic steel coil sheet covering machine, the packaging process has become faster, more accurate, and highly efficient.

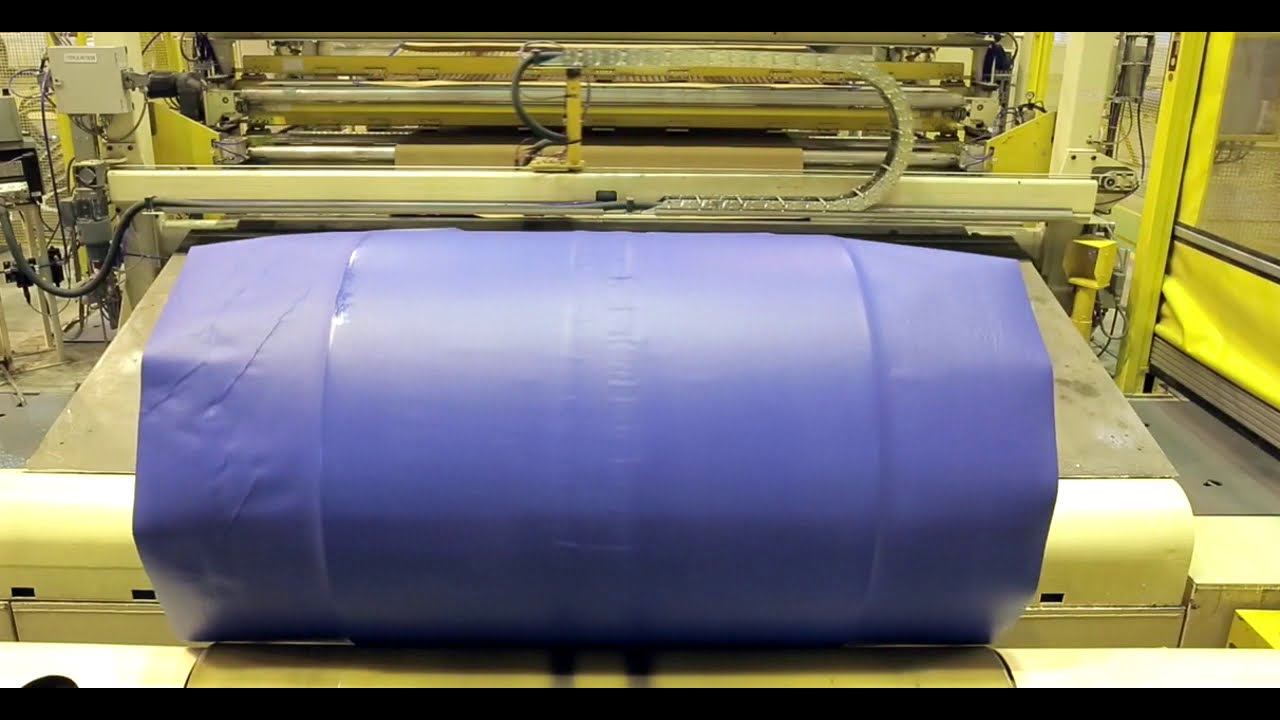

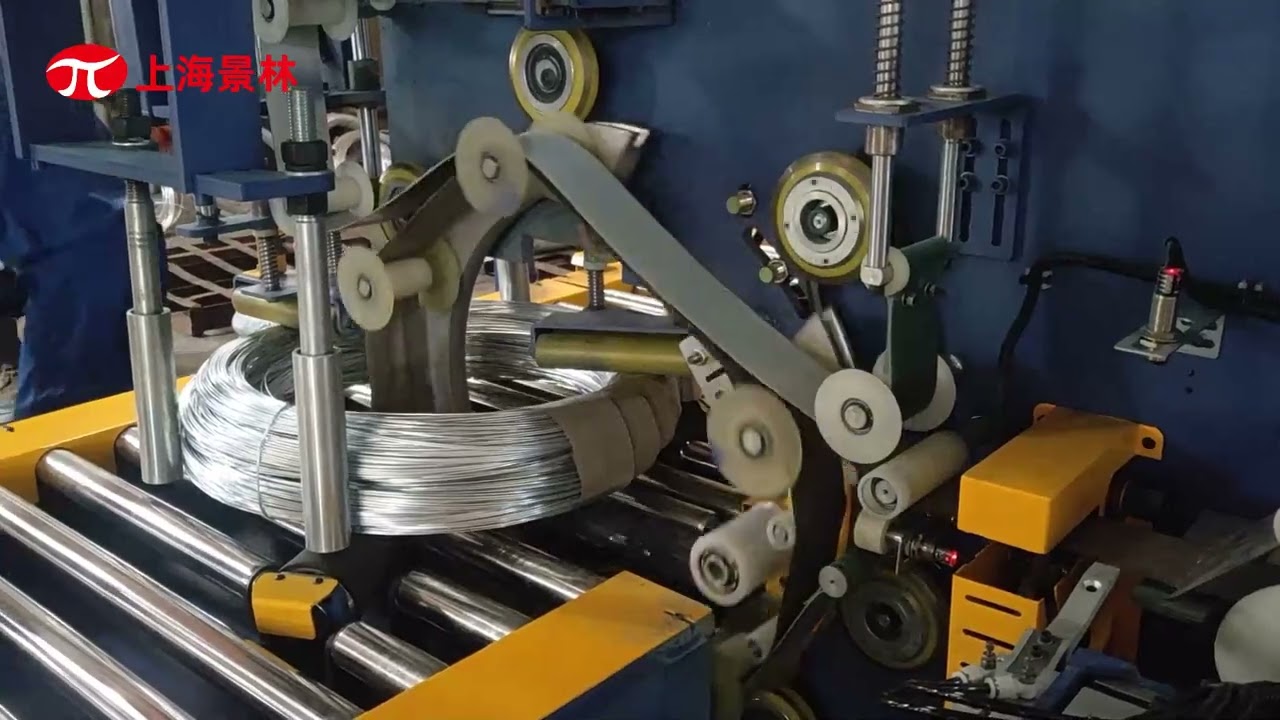

The automatic feeding and sheet covering machine is designed to handle the entire packaging process seamlessly. It starts with the automatic feeding of the cold roll steel coils onto the conveyor belt. This eliminates the need for manual labor and ensures a continuous and uninterrupted flow of coils. The machine then automatically applies a layer of paper or steel sheet to cover the coil's surface. This protective layer shields the coil from potential damage caused by moisture, dust, or any external factors.

One of the most impressive features of this machine is its precision and accuracy. The automatic feeding mechanism ensures that each coil is placed in the correct position on the conveyor belt, eliminating any misalignment issues. The sheet covering process is also highly accurate, with the machine applying the paper or steel sheet evenly and tightly onto the coil's surface. This ensures that the coil is fully protected and ready for transportation or storage.

Moreover, the automatic steel coil sheet covering machine is equipped with advanced sensors and control systems. These sensors detect any irregularities or abnormalities in the packaging process, such as coil misalignment or sheet tearing. Once detected, the machine automatically adjusts its operation to rectify the issue, ensuring that every coil is packaged flawlessly. This not only enhances the overall quality of the packaging but also reduces the chances of product damage during transportation.

In addition to its efficiency and accuracy, this machine offers several other advantages. Firstly, it greatly reduces labor costs as it eliminates the need for manual handling and packaging. This allows companies to allocate their resources more effectively and focus on other aspects of their operations. Secondly, it increases productivity by significantly reducing the time required for the packaging process. With faster and more efficient packaging, companies can meet their production targets more easily.

Furthermore, the automatic steel coil sheet covering machine improves the overall quality of the packaging. The precision and accuracy of the machine ensure that each coil is protected with a consistent and tight covering. This not only enhances the visual appeal of the packaged coils but also provides reliable protection against external elements. As a result, companies can deliver high-quality products to their customers, reinforcing their reputation in the market.

In conclusion, the automatic steel coil sheet covering machine has revolutionized the coil packing line industry. With its advanced features, precision, and efficiency, it has become an indispensable tool for companies in the steel sector. This machine not only improves the overall quality of the packaging but also reduces labor costs and increases productivity. As the manufacturing industry continues to evolve, technologies like this will play a crucial role in streamlining operations and enhancing efficiency.

coil packing line

"Efficient Steel Coil Packing Solutions: Automate Your Packing Line with the Advanced Coil Sheet Covering Machine"