Copper coil packing line: Revolutionizing the Packaging Industry

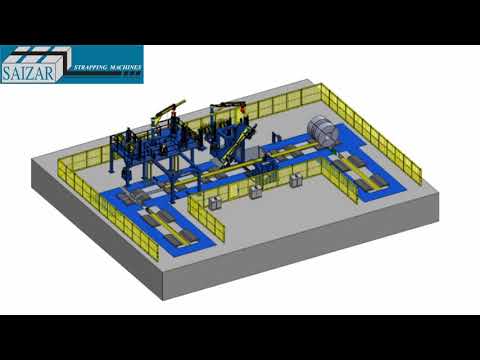

The coil packing line has become an indispensable part of the manufacturing sector, particularly in the field of copper coil packaging. This sophisticated machinery has the ability to streamline the packaging process, ensuring efficiency, accuracy, and cost-effectiveness. In this article, we will delve into the features and benefits of the coil packing line, specifically focusing on the automatic bagged packing line for copper coil.

The automatic bagged packing line for copper coil is a game-changer in the packaging industry. With its advanced technology and precision, it has transformed the way copper coils are packaged, making it a preferred choice for manufacturers worldwide. This innovative equipment offers numerous advantages, such as increased productivity, improved safety measures, and enhanced product protection.

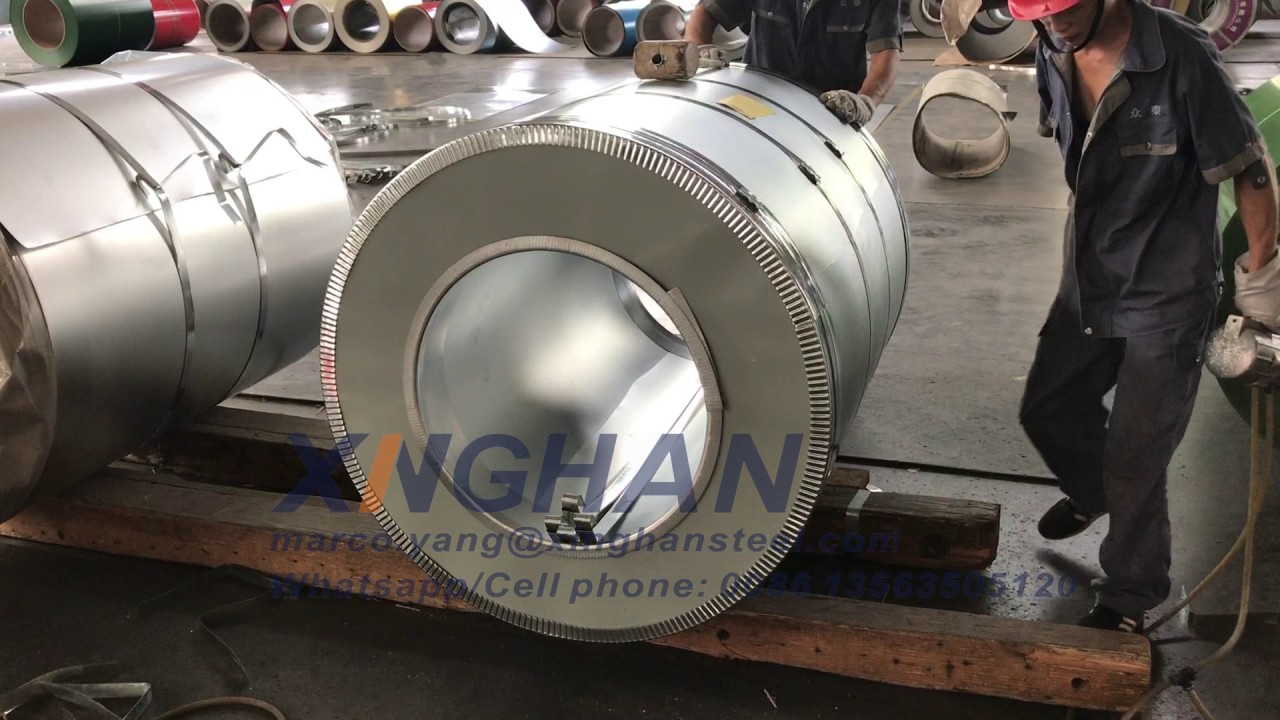

One of the key features of the coil packing line is its ability to handle a wide range of coil sizes and weights. This versatility ensures that manufacturers can package their copper coils efficiently, regardless of their dimensions. The machine is equipped with state-of-the-art sensors and controls, allowing it to adapt to different coil sizes seamlessly. This eliminates the need for manual adjustments, saving valuable time and effort.

Moreover, the automatic bagged packing line is designed to optimize the use of packaging materials. By precisely measuring and cutting the required amount of packaging material, it minimizes wastage and reduces costs. This eco-friendly approach not only benefits the environment but also contributes to the overall sustainability of the manufacturing process.

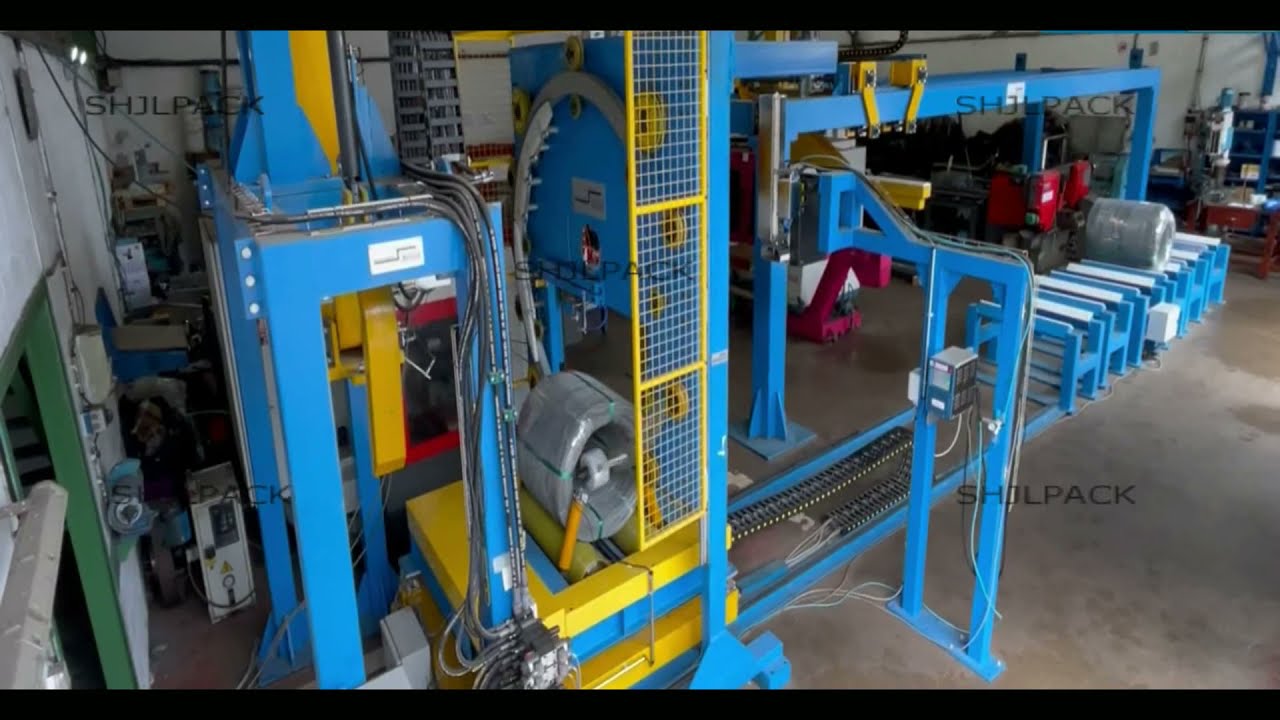

Safety is of utmost importance in any industrial setting, and the coil packing line prioritizes this aspect. The machine incorporates various safety features, such as emergency stop buttons, safety barriers, and sensors to detect any potential hazards. This ensures the well-being of the operators and prevents accidents, ultimately leading to a safer working environment.

In addition to safety, the coil packing line significantly reduces the risk of product damage during packaging. The precise and controlled handling of the copper coils minimizes the chances of scratches, dents, or other forms of damage. This is particularly crucial for delicate products like copper coils, as any impairment can affect their performance and functionality.

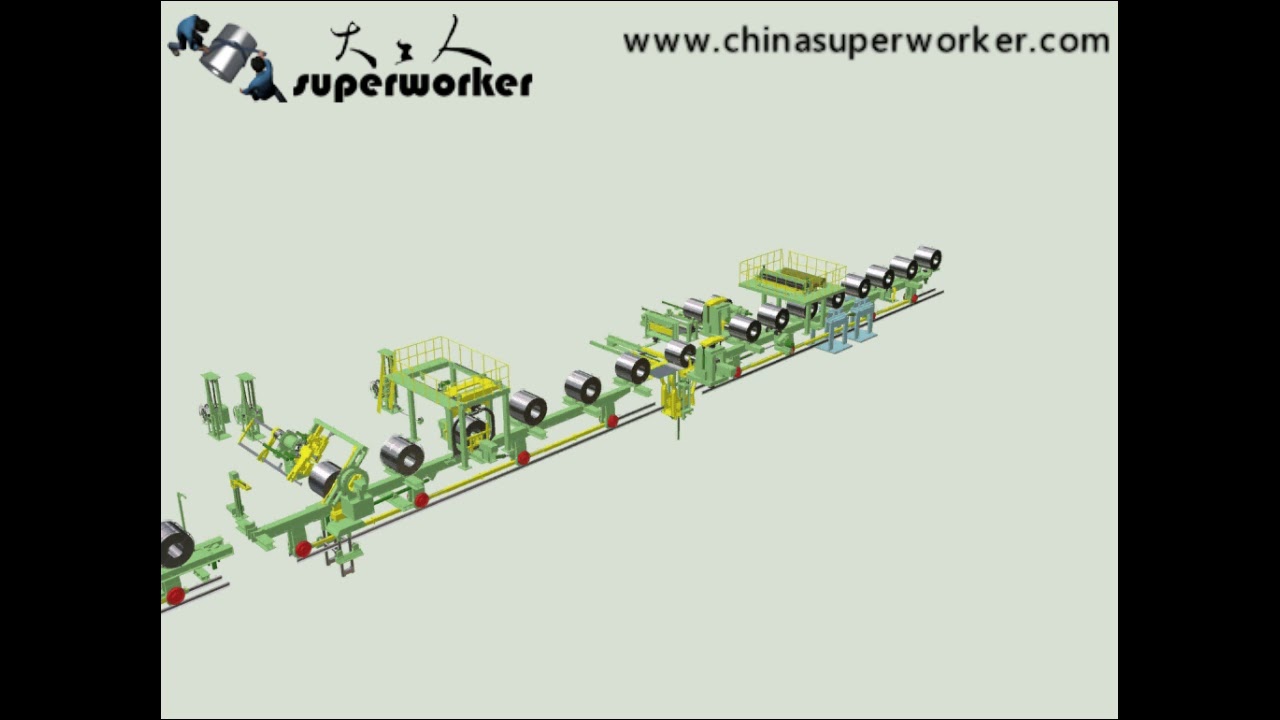

The coil packing line also offers a high level of automation, further enhancing efficiency and productivity. By automating the packaging process, manufacturers can save time and resources that were previously spent on manual labor. The machine can operate continuously, with minimal human intervention, resulting in a faster and more streamlined production line.

With the increasing demand for copper coils in various industries, the coil packing line has become a vital asset for manufacturers. Its ability to package the coils efficiently and securely ensures that they reach their destination in perfect condition. This not only enhances customer satisfaction but also strengthens the reputation of the manufacturer in the market.

Furthermore, the coil packing line enables manufacturers to meet stringent quality standards and comply with industry regulations. The machine ensures that each coil is packaged according to the required specifications, leaving no room for errors or inconsistencies. This level of precision and adherence to standards is crucial, especially in industries where quality control is paramount.

The coil packing line has undoubtedly revolutionized the packaging industry, particularly in the context of copper coil packaging. Its advanced features, automated processes, and emphasis on safety and product protection have made it an indispensable tool for manufacturers. As the demand for copper coils continues to rise, the coil packing line will play a pivotal role in meeting the ever-growing requirements of the market.

In conclusion, the coil packing line has transformed the way copper coils are packaged, offering numerous benefits to manufacturers. The automatic bagged packing line, with its versatility, efficiency, and emphasis on safety, has become a preferred choice for packaging copper coils. Its ability to handle various coil sizes, optimize packaging materials, and automate the process has revolutionized the industry. As the demand for copper coils continues to soar, the coil packing line will undoubtedly remain at the forefront of innovation in the packaging sector.

coil packing line

"Efficient Bagged Packing Solutions for Copper Coil and Coil Packing Line: Streamlining the Packaging Process"