Coil Packing Line: Enhancing Efficiency and Productivity

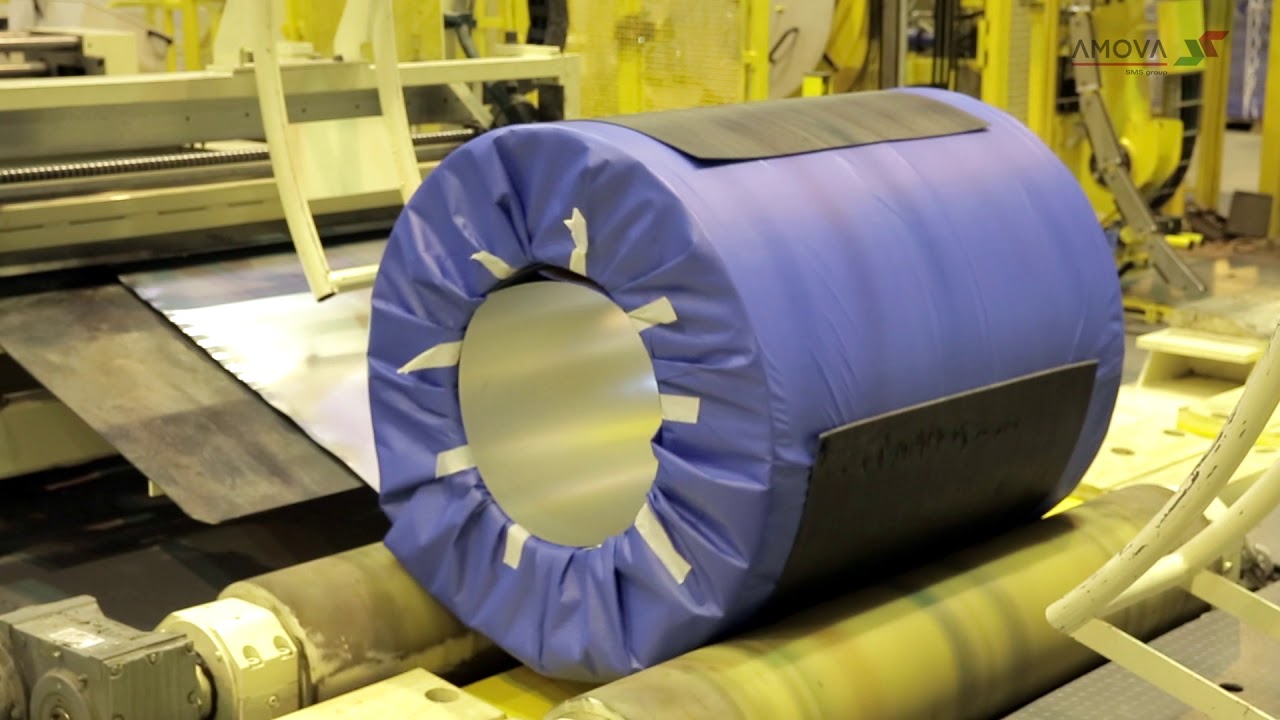

Coil packing is a critical process in various industries, including manufacturing and logistics. It involves securely packaging coils to ensure their safety during transportation and storage. As technology continues to advance, companies are constantly seeking innovative solutions to streamline their coil packing operations. One such solution that has gained significant attention is the Coil Packing Line with Tilter and Stacking Function.

This cutting-edge machine, developed by an industry-leading provider, revolutionizes the coil packing process. Its advanced features and functionalities not only enhance efficiency but also improve productivity, ultimately benefiting businesses across the globe.

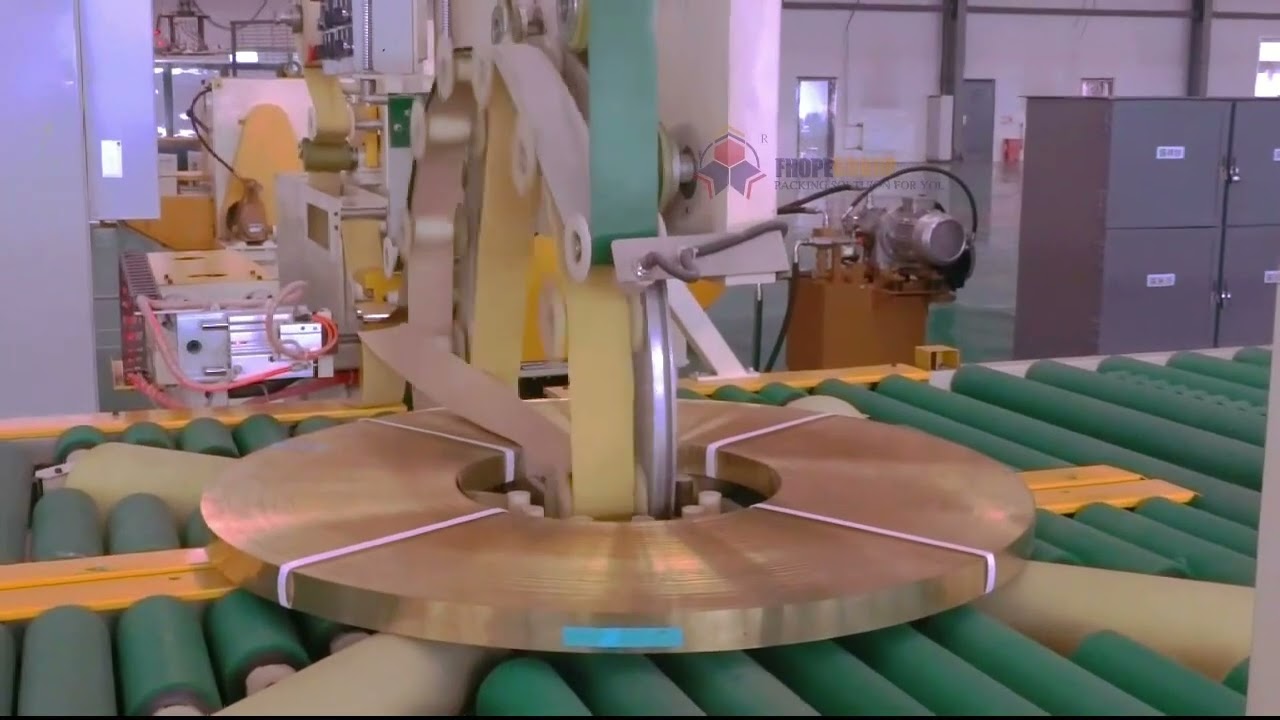

The coil packing line is designed to handle a wide range of coil sizes and weights, making it versatile and adaptable to different industry requirements. Its key feature, the tilter, allows for ergonomic loading and unloading of coils. This function significantly reduces the strain on operators, minimizing the risk of injuries and improving overall workplace safety.

Additionally, the stacking function of the coil packing line enables efficient coil storage. The machine can stack coils in a neat and organized manner, optimizing warehouse space utilization. This feature is particularly useful for companies with limited storage capacity, as it allows them to maximize their available space and reduce costs associated with additional storage facilities.

Furthermore, the coil packing line is equipped with state-of-the-art automation technology. This automation ensures precise and consistent wrapping of coils, eliminating human errors and enhancing the overall quality of the packaging. By automating the process, businesses can achieve higher production rates and reduce labor costs.

The integration of advanced control systems into the coil packing line further enhances its efficiency. These control systems allow for easy customization of packaging parameters, ensuring that each coil is packed according to the specific requirements of the industry or customer. This flexibility is crucial in meeting the diverse needs of different applications and maintaining customer satisfaction.

Moreover, the coil packing line is designed with sustainability in mind. It incorporates energy-saving features and materials that minimize environmental impact. By reducing energy consumption and waste generation, companies can contribute to a greener future while also benefiting from cost savings.

The benefits of the coil packing line with tilter and stacking function are evident across various industries. Manufacturers can significantly increase their production capacity while maintaining high-quality packaging standards. Logistics companies can optimize their storage space and improve inventory management. Ultimately, these improvements lead to enhanced customer satisfaction and increased competitiveness in the market.

As businesses continue to invest in advanced technologies like the coil packing line, it is crucial to ensure proper training and support for operators. While the machine simplifies the packing process, it still requires skilled personnel to operate and maintain it effectively. Companies should invest in comprehensive training programs to equip their employees with the necessary knowledge and skills.

In conclusion, the coil packing line with tilter and stacking function represents a significant advancement in coil packaging technology. Its innovative features, such as the tilter and stacking function, automation, and advanced control systems, enhance efficiency, productivity, and quality. Moreover, its sustainability features align with the growing focus on environmental responsibility. By investing in this state-of-the-art machine, businesses can streamline their coil packing operations, reduce costs, and achieve a competitive edge in the market.

coil packing line

"Efficient Coil Packing Line: Tilter and Stacking Functions Streamline Packaging Process"