Coil Packaging Line: Revolutionizing the Copper Pipe Industry

The copper pipe industry has witnessed a remarkable transformation in recent years, thanks to the introduction of advanced technologies such as the coil packing line. This cutting-edge solution has revolutionized the way copper pipes are packaged and transported, ensuring efficiency, safety, and cost-effectiveness throughout the entire process.

In the world of copper pipe manufacturing, the need for a reliable and efficient packaging solution has always been a priority. Traditionally, the process of packaging coils of copper pipes was labor-intensive and time-consuming. However, with the advent of the coil packing line, these challenges are now a thing of the past.

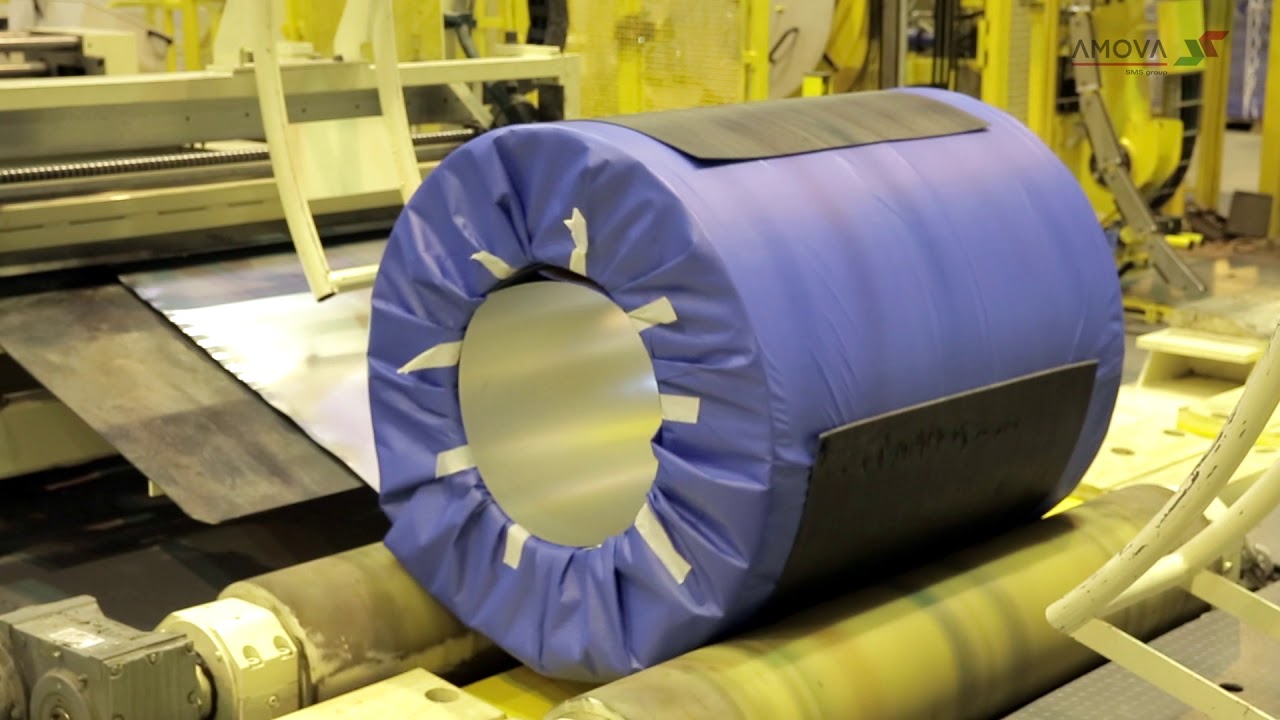

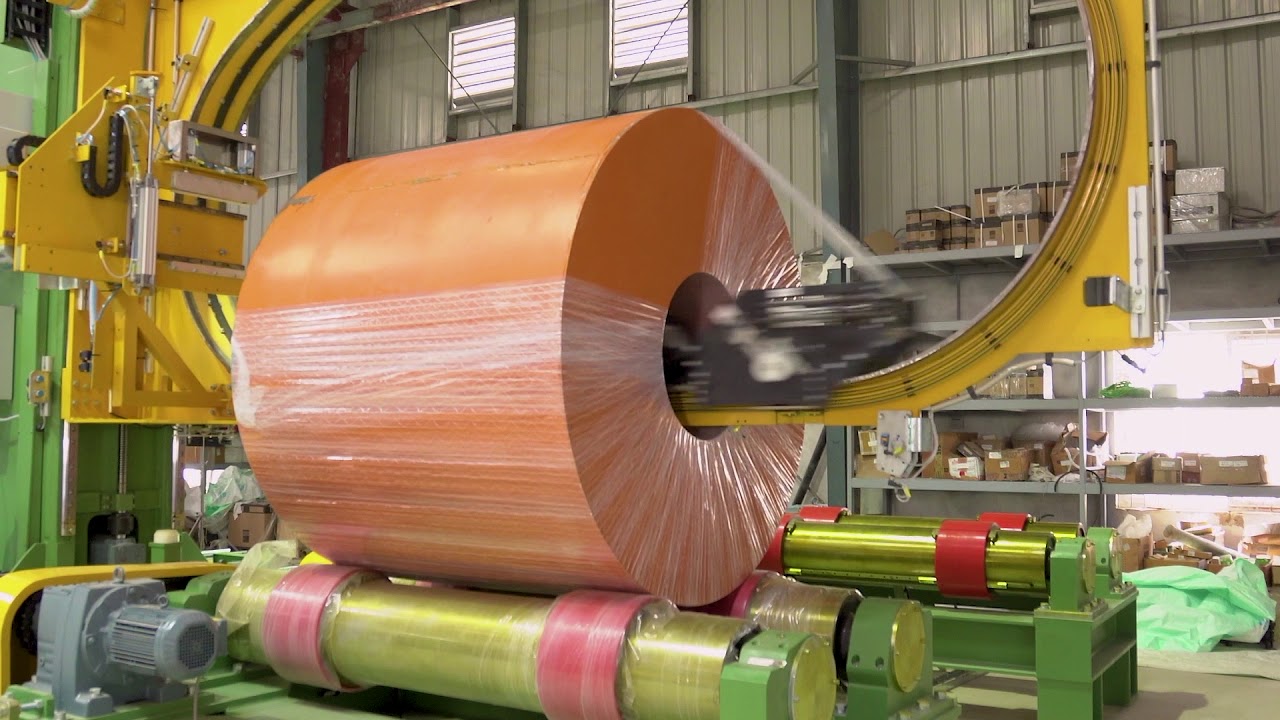

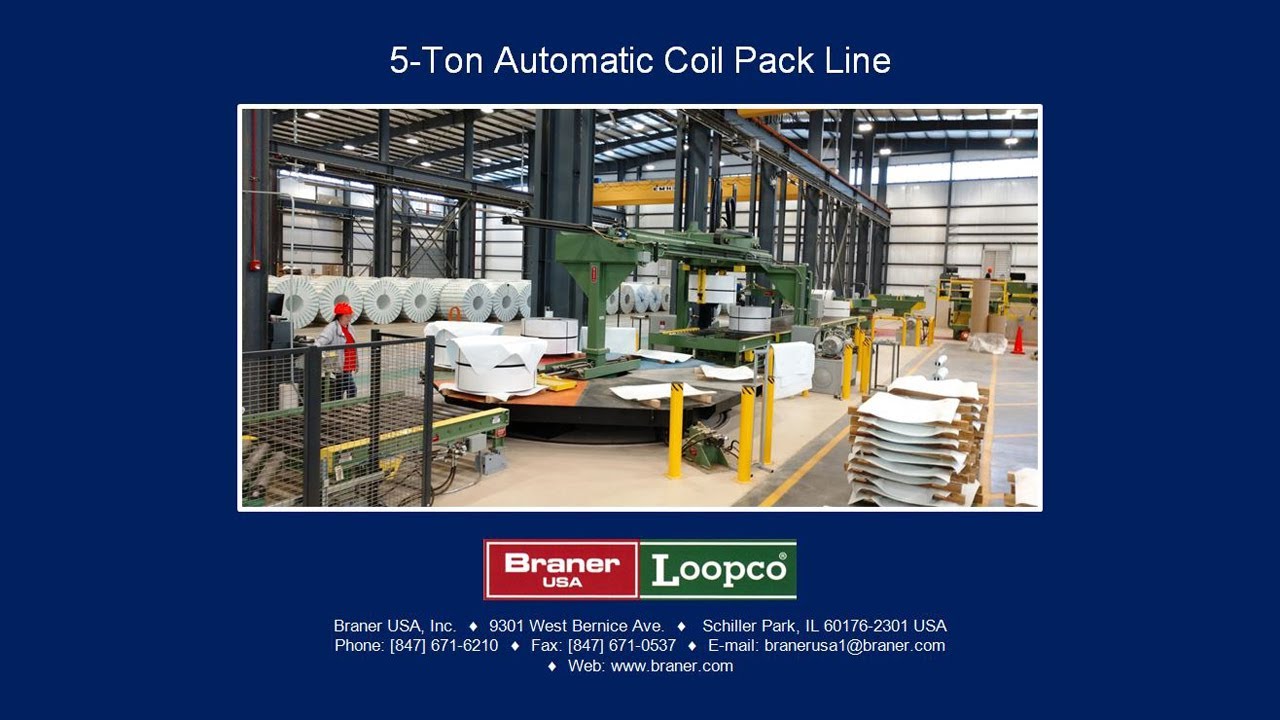

The coil packing line is a horizontal type copper pipe coil packing line that automates the packaging process from start to finish. Equipped with state-of-the-art technology, this innovative system has transformed the way copper pipes are handled, offering numerous benefits to manufacturers, distributors, and end-users alike.

One of the key advantages of the coil packing line is its ability to streamline the packaging process. With its high-speed operation and advanced control system, this cutting-edge solution can significantly increase productivity while reducing labor costs. Furthermore, the automated nature of the system ensures consistent and precise packaging, eliminating the risk of human error.

In addition to its efficiency, the coil packing line also prioritizes safety. The system is designed to handle the packaging of coils of copper pipes with utmost care, minimizing the risk of damage or accidents during transportation. Its robust construction and advanced safety features provide manufacturers with peace of mind, knowing that their products will reach their destinations in perfect condition.

Moreover, the coil packing line offers enhanced versatility, allowing manufacturers to customize their packaging according to specific requirements. The system can accommodate coils of different sizes and shapes, ensuring a seamless packaging process regardless of the variations in product specifications. This flexibility allows manufacturers to cater to a wide range of customer demands, further boosting their competitiveness in the market.

From a sustainability perspective, the coil packing line also offers significant advantages. By automating the packaging process, manufacturers can optimize the use of packaging materials, reducing waste and minimizing their environmental footprint. This not only benefits the planet but also enhances the reputation of companies as responsible and eco-conscious entities.

The impact of the coil packing line on the copper pipe industry has been nothing short of transformative. Manufacturers have experienced increased efficiency, reduced costs, improved safety measures, and enhanced flexibility in their operations. Distributors and end-users, on the other hand, have benefited from the consistent quality of packaged copper pipes and the timely delivery of products.

Looking ahead, the future of the coil packing line seems promising. As technology continues to advance, we can expect further innovations in this field, leading to even more efficient and sustainable packaging solutions. The industry is poised for growth and continuous improvement, driven by the commitment of manufacturers to embrace cutting-edge technologies and meet the evolving needs of their customers.

In conclusion, the coil packing line has revolutionized the copper pipe industry, offering an automated, efficient, and safe solution for packaging coils of copper pipes. With its advanced technology and versatility, this horizontal type copper pipe coil packing line has transformed the way manufacturers operate, ensuring consistent quality, reducing costs, and enhancing sustainability. As we move forward, it is exciting to anticipate the further advancements that will shape the future of this industry and continue to drive its success.

coil packing line

"Efficient Packaging Solutions for Horizontal Copper Pipe Coil Production"