Coil Packing Line: Revolutionizing the Steel Industry

The manufacturing industry has always been at the forefront of innovation, constantly seeking ways to improve efficiency and productivity. One such breakthrough in the steel industry is the introduction of the Automatic Steel Slit Coil Packaging Line. This cutting-edge technology has revolutionized the way steel coils are packed, ensuring a seamless process from start to finish. In this article, we will delve into the various aspects of the coil packing line, highlighting its key features and benefits.

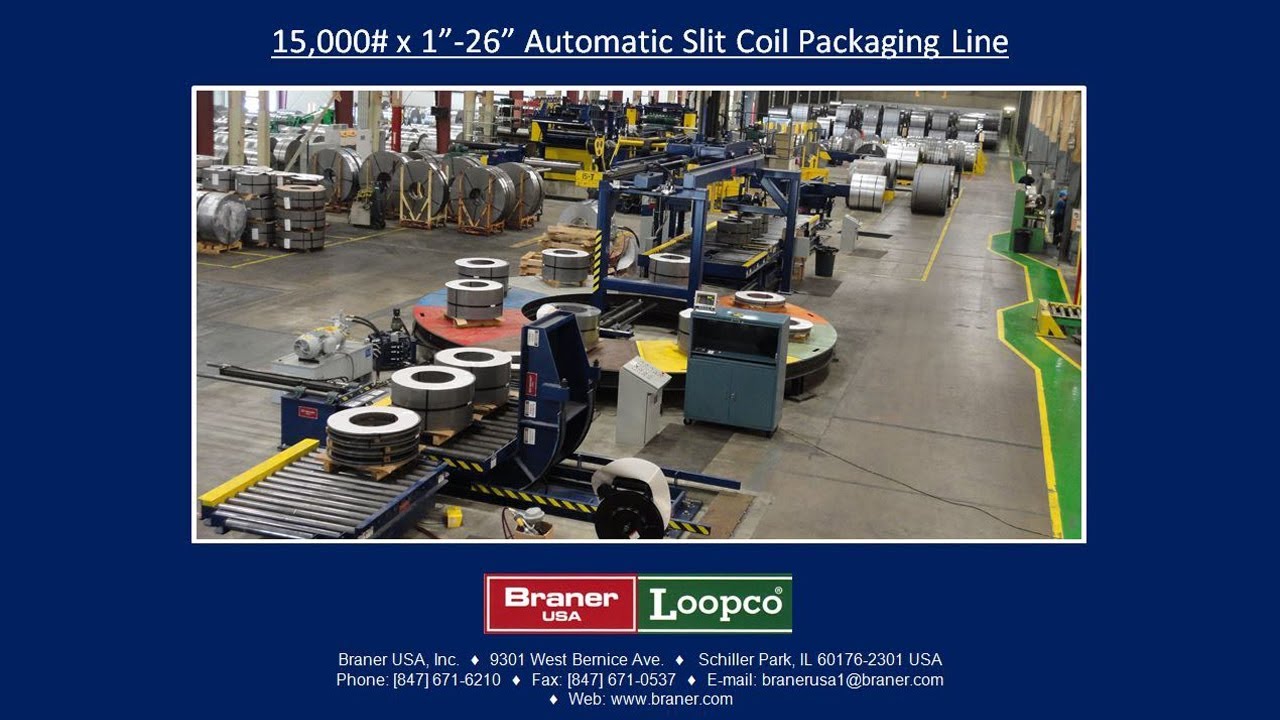

The coil packing line is a marvel of engineering, designed to handle every step of the packaging process with precision and speed. From coil picking and tilting to wrapping, pallet carrying, labeling, and centering, this state-of-the-art system streamlines operations, saving both time and labor costs. Let’s take a closer look at each of these work modules.

Coil picking and tilting is the first step in the packaging process. The automatic system carefully selects the steel coils, ensuring that they are securely held in place during transportation. By minimizing human intervention, the risk of accidents and injuries is significantly reduced.

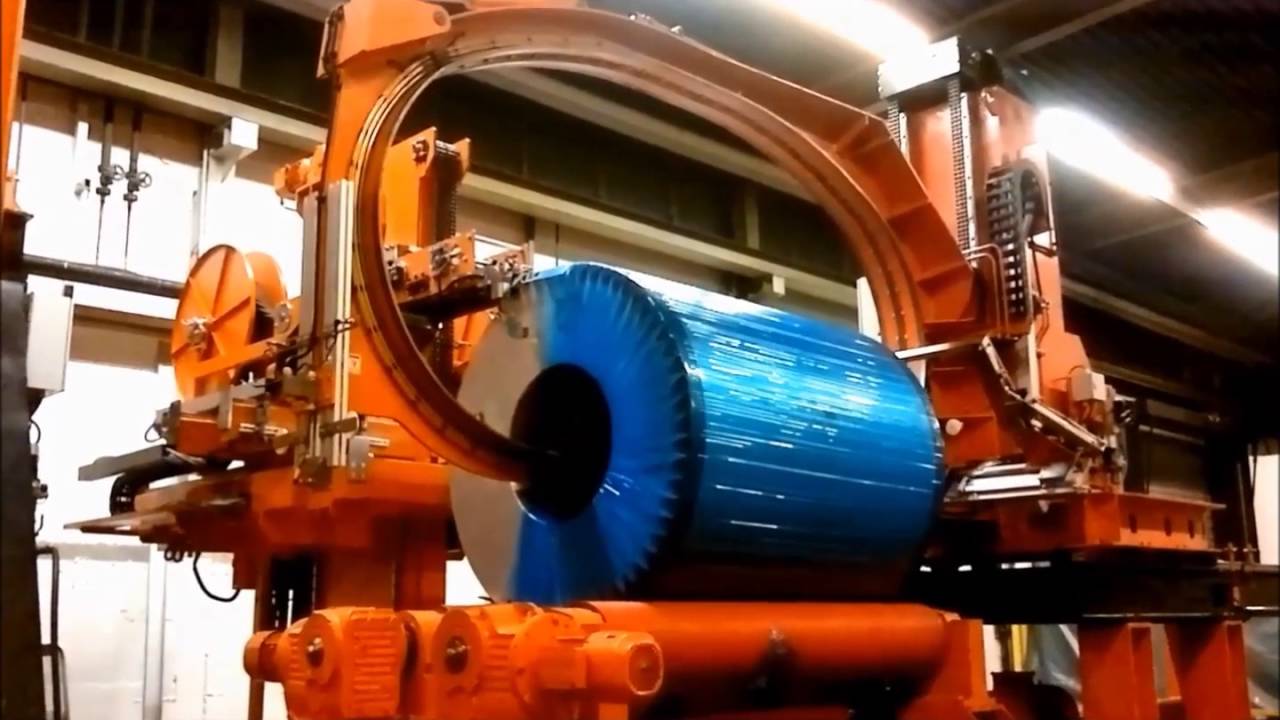

Once the coils are picked, the wrapping module comes into play. This is where the steel coils are tightly wrapped in protective material, ensuring that they are shielded from any external damage. The wrapping process is automated, guaranteeing uniform wrapping and eliminating the possibility of errors or inconsistencies.

After wrapping, the pallet carrying module takes over. The packaged steel coils are carefully placed on pallets, ready for transportation. The system optimizes the placement of the coils on the pallet, maximizing space utilization and minimizing the risk of damage during transit.

Labeling is another crucial aspect of the coil packing line. Each packaged coil is assigned a unique label, containing important information such as product details, batch number, and destination. The automatic labeling system ensures accurate labeling, reducing the chances of mix-ups or confusion.

Finally, the centering module ensures that the packaged coils are perfectly aligned on the pallet. This not only enhances the visual appeal of the final product but also facilitates easy loading and unloading, further streamlining the logistics process.

The benefits of the coil packing line are manifold. Firstly, it significantly reduces labor costs by automating repetitive tasks, allowing workers to focus on more complex and value-added activities. This not only improves productivity but also enhances overall worker satisfaction.

Secondly, the coil packing line improves the efficiency of the packaging process. By eliminating manual errors and inconsistencies, it ensures that every packaged coil meets the highest quality standards. This, in turn, enhances customer satisfaction and reduces the chances of product returns or complaints.

Furthermore, the coil packing line improves workplace safety. With minimal human intervention required, the risk of accidents and injuries is greatly reduced. This creates a safer working environment and instills confidence in the workforce.

In conclusion, the coil packing line is a game-changer in the steel industry. Its ability to seamlessly handle every step of the packaging process, from coil picking and tilting to wrapping, pallet carrying, labeling, and centering, has revolutionized the way steel coils are packed. With its numerous benefits, including improved efficiency, reduced labor costs, enhanced product quality, and increased workplace safety, the coil packing line is a must-have for any steel manufacturing facility. Embracing this cutting-edge technology will undoubtedly propel the industry forward, cementing its position as a leader in innovation and progress.

coil packing line

“Efficient and Reliable Packaging Solutions for Steel Slit Coils: Enhance Productivity with Automated Coil Packing System”