Title: Revolutionizing Coil Packaging: A New Era of Efficiency

In the fast-paced world of manufacturing, staying ahead of the game requires constant innovation and optimization. For companies that deal with the production and packaging of coils, the use of a coil packing line has become a necessity. Its ability to streamline processes and enhance productivity has made it an indispensable tool in the industry. Today, we delve into the advantages of the coil packing line and explore how Braner Loopco's Coil Pack Line is revolutionizing the way coils are packaged.

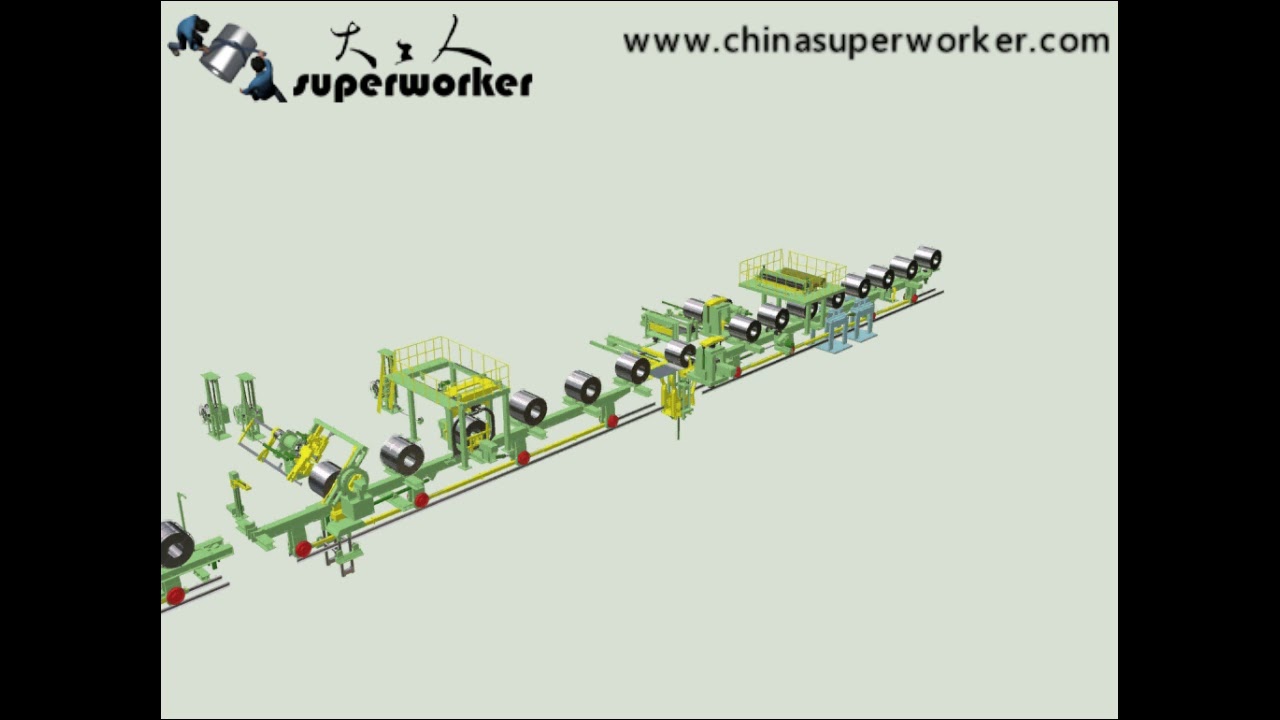

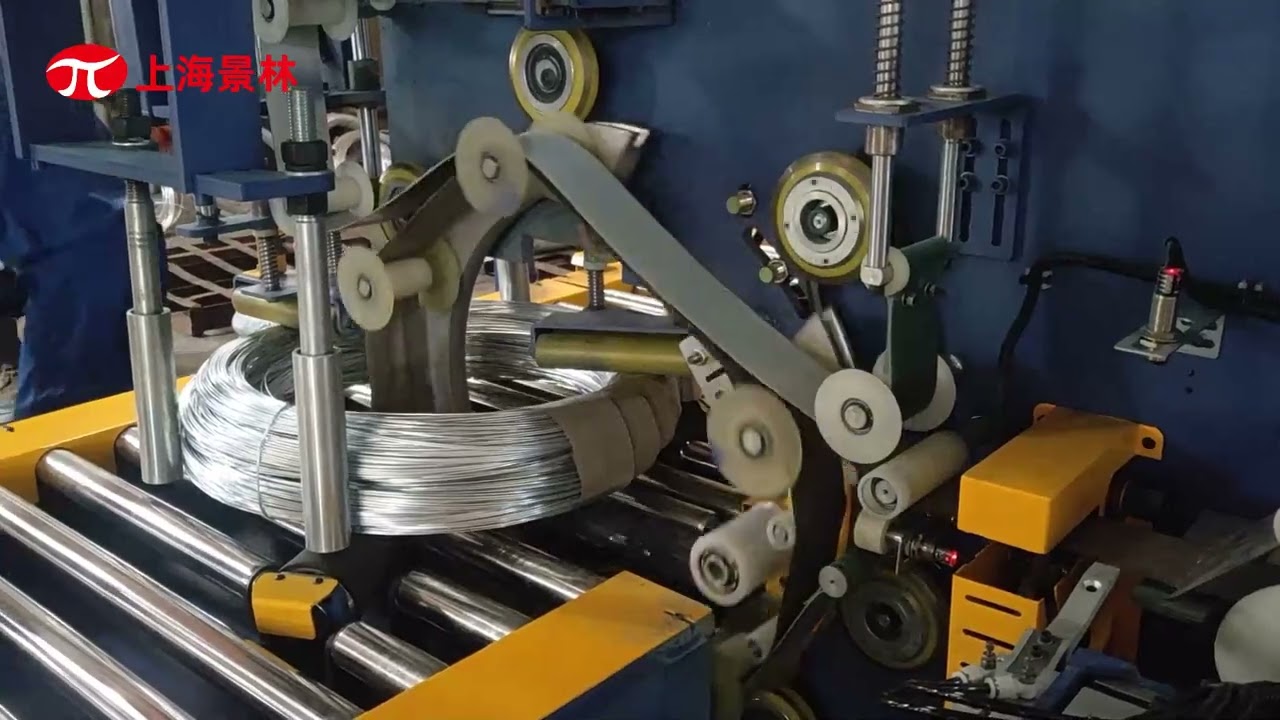

Efficiency, productivity, and cost-effectiveness are key factors driving the adoption of coil packing lines. These automated systems are designed to handle the packaging of coiled materials swiftly and accurately. By eliminating the need for manual intervention, companies can significantly reduce labor costs and minimize the risk of errors. With the ability to handle various coil sizes and configurations, the coil packing line caters to a wide range of production requirements.

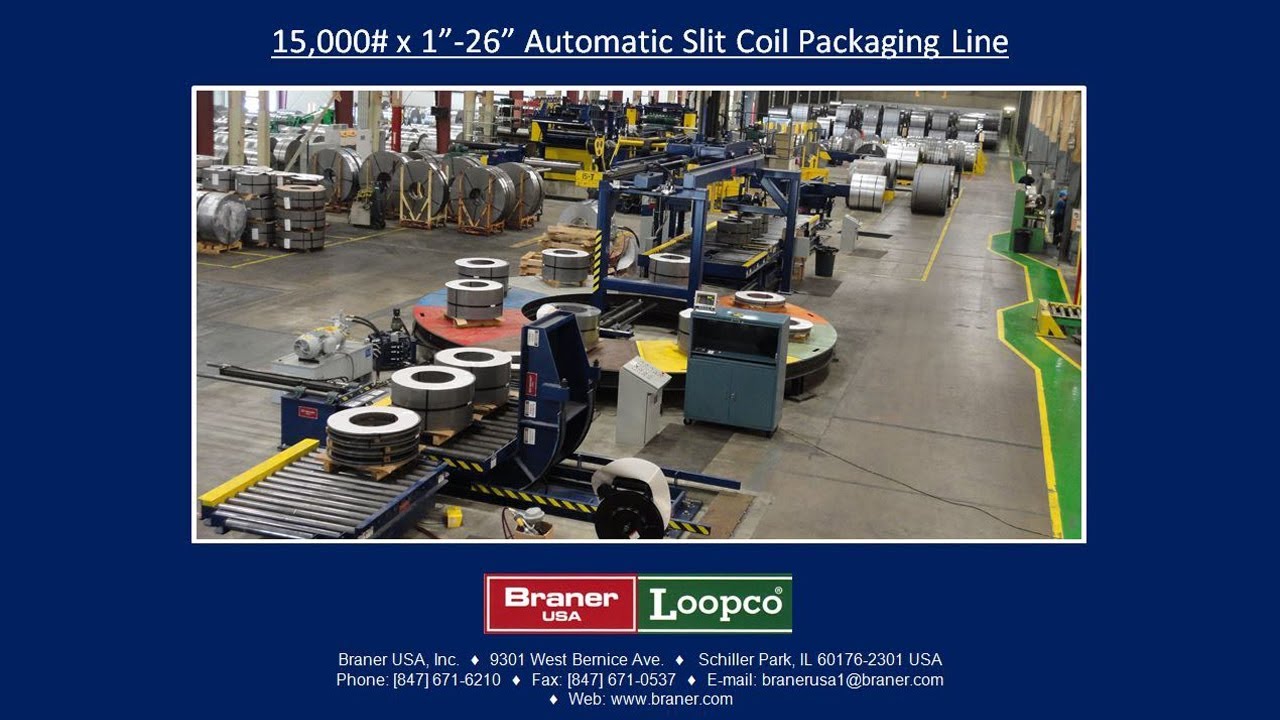

Braner Loopco, a leading manufacturer of coil processing equipment, has taken coil packaging to new heights with their innovative Coil Pack Line. This state-of-the-art solution brings together cutting-edge technology and advanced features to enhance the packaging process. From start to finish, the Coil Pack Line ensures a seamless and efficient operation, delivering high-quality results every time.

The Coil Pack Line by Braner Loopco boasts an impressive array of features that set it apart from the competition. With its advanced coil handling system, the line can accommodate a variety of coil sizes, weights, and materials. This adaptability makes it a versatile solution for manufacturers dealing with multiple coil types.

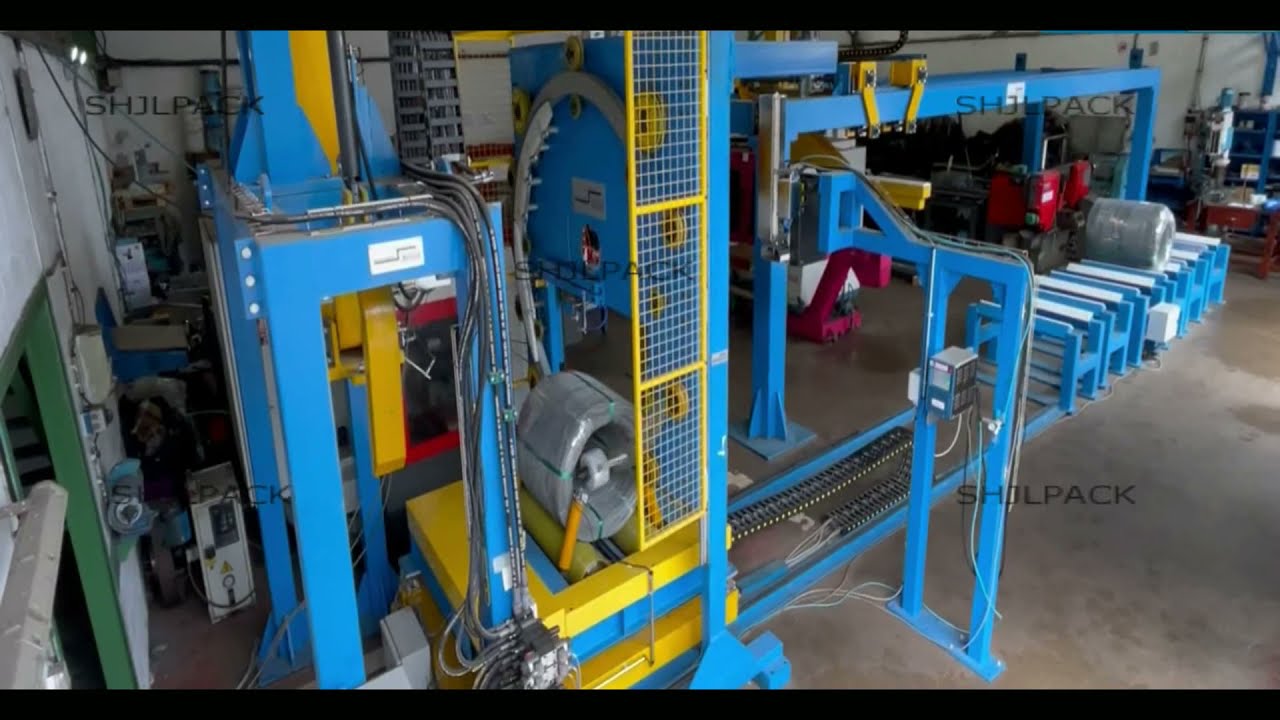

One of the standout features of the Coil Pack Line is its intelligent control system. This system allows for precise control of the packaging process, ensuring optimal tension and protection for the coils. By minimizing the risk of damage during transportation and storage, manufacturers can maintain product integrity and minimize waste.

The Coil Pack Line also incorporates advanced material handling mechanisms that facilitate smooth coil transfer throughout the packaging process. This eliminates the need for manual intervention, reducing the risk of injuries and improving overall safety in the workplace. With safety being a top priority in any manufacturing environment, Braner Loopco's Coil Pack Line provides peace of mind to both operators and business owners.

Furthermore, the Coil Pack Line embraces automation to its fullest potential. By integrating robotics and smart technology, the line maximizes efficiency and minimizes downtime. The automated processes ensure consistent and reliable packaging, allowing manufacturers to meet strict deadlines and exceed customer expectations.

In addition to its impressive features, the Coil Pack Line also offers a user-friendly interface. The intuitive control panel enables operators to easily monitor and adjust the packaging parameters, ensuring precise and customized packaging for each coil. This seamless integration of technology and user-friendliness makes the Coil Pack Line accessible to both seasoned professionals and those new to the industry.

As the demand for coil packaging continues to grow, Braner Loopco's Coil Pack Line is setting new industry standards. Its ability to optimize efficiency, enhance productivity, and reduce costs has garnered attention from manufacturers worldwide. By investing in this cutting-edge technology, companies can gain a competitive edge in an ever-evolving market.

In conclusion, the coil packing line has revolutionized the way coils are packaged, and Braner Loopco's Coil Pack Line is leading the charge in this transformative era. With its advanced features, intelligent control system, and seamless automation, this innovative solution is driving efficiency and productivity to new heights. Manufacturers that embrace the Coil Pack Line can unlock a world of possibilities, ensuring success in a fast-paced and demanding industry.

coil packing line

"Optimizing Coil Packaging Efficiency: Streamlining Your Production Line with Advanced Technology"