In a steel cold rolling project, the introduction of packaging units plays a crucial role in ensuring the efficiency and integrity of the process. Today, we will delve into the world of coil packing lines, specifically focusing on the closed type I packaging unit connected to two galvanizing units. This article will provide an in-depth analysis of the cold rolled coil packaging work steps, shedding light on the intricate details of this essential aspect of the steel industry.

The coil packing line is a critical component of the steel cold rolling project, ensuring that the finished product is protected and ready for transportation. The closed type I packaging unit, connected to two galvanizing units, facilitates the packaging process by creating a secure and efficient environment. This configuration allows for seamless integration of the galvanizing units into the packaging line, streamlining the overall workflow.

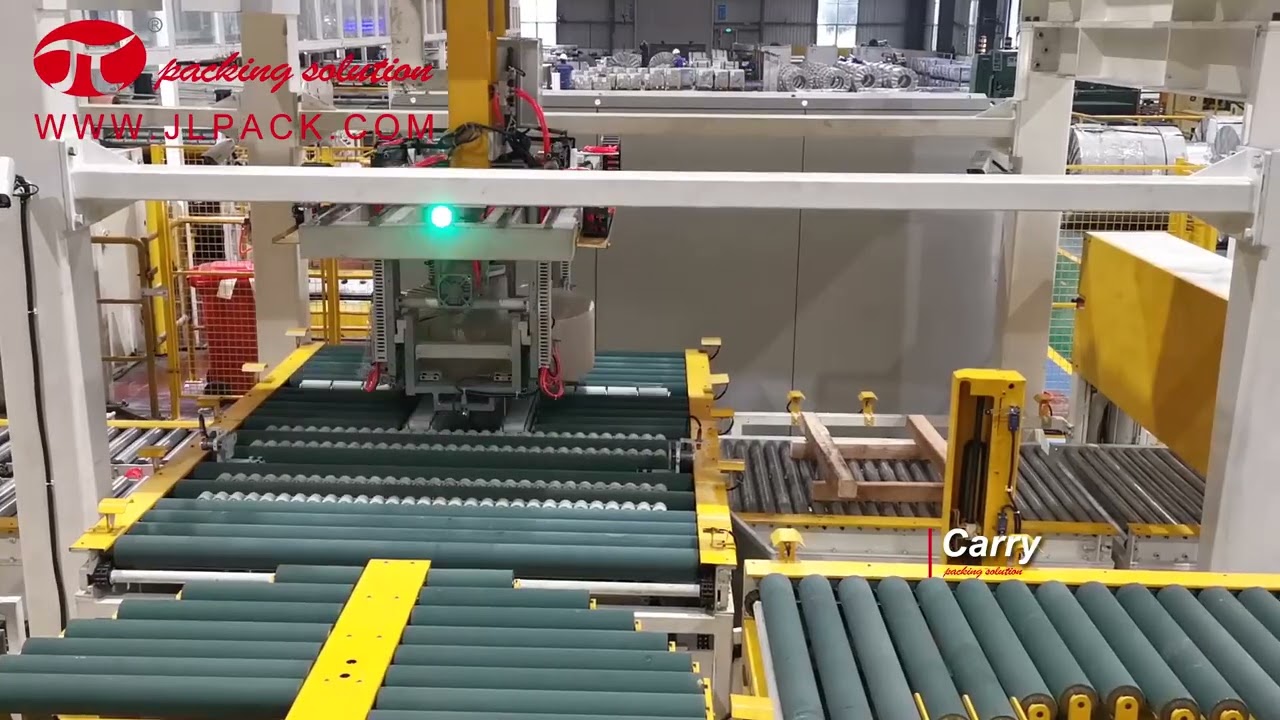

Cold rolled coil packaging work steps involve a series of carefully orchestrated procedures to ensure the coils are adequately protected. The process begins with the loading of the coils onto a conveyor system, which transports them to the packaging unit. Here, the coils are inspected for any visible defects or damage, ensuring that only high-quality products proceed further.

Once the inspection is complete, the coils are securely strapped to prevent any movement during the packaging process. This step is crucial in maintaining the structural integrity of the coils and minimizing the risk of damage. The closed type I packaging unit provides a controlled environment, protecting the coils from external elements such as dust, moisture, and temperature fluctuations.

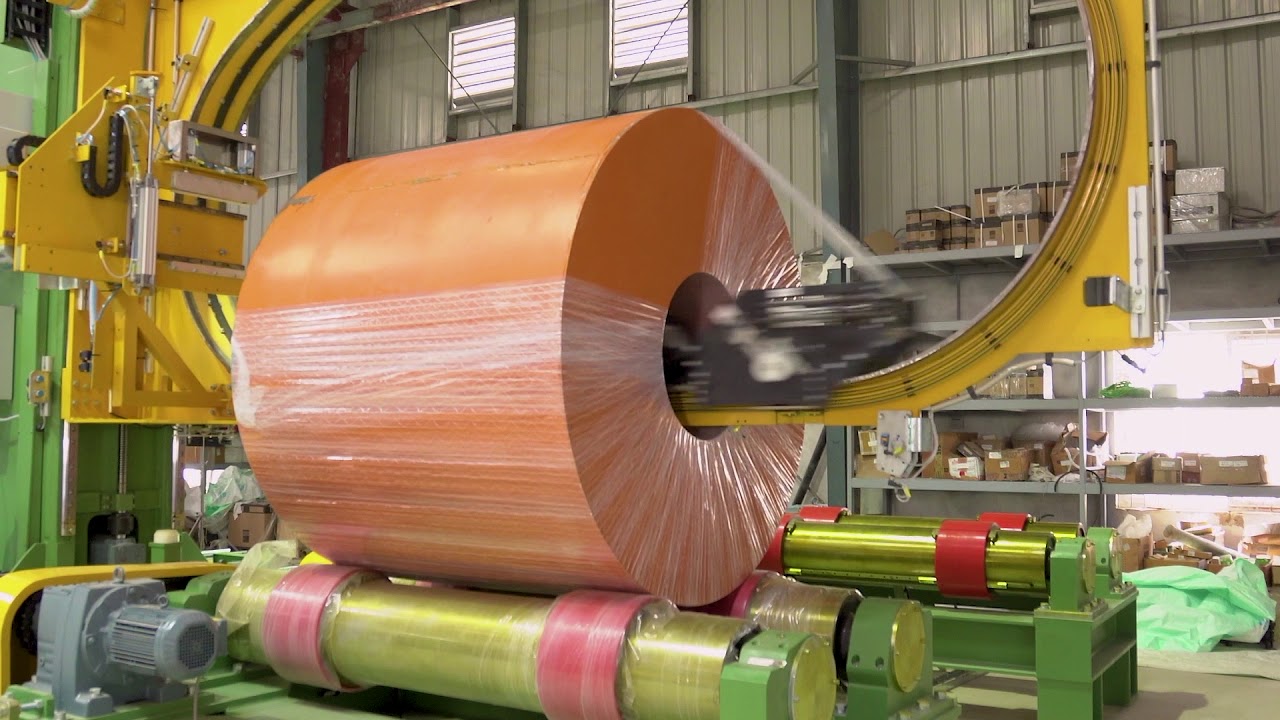

After the coils are strapped, they are fed into the packaging unit, where they are wrapped with a protective material. This material acts as a barrier against potential scratches or abrasions during transportation. The closed type I packaging unit ensures that the material is tightly wrapped around the coils, providing an additional layer of protection.

Connected to the packaging unit are two galvanizing units, which play a vital role in enhancing the durability and longevity of the coils. Galvanizing is a process that involves applying a protective zinc coating to the steel surface, preventing corrosion and extending the lifespan of the coils. The integration of these galvanizing units within the packaging line allows for a seamless transition from packaging to the galvanizing process.

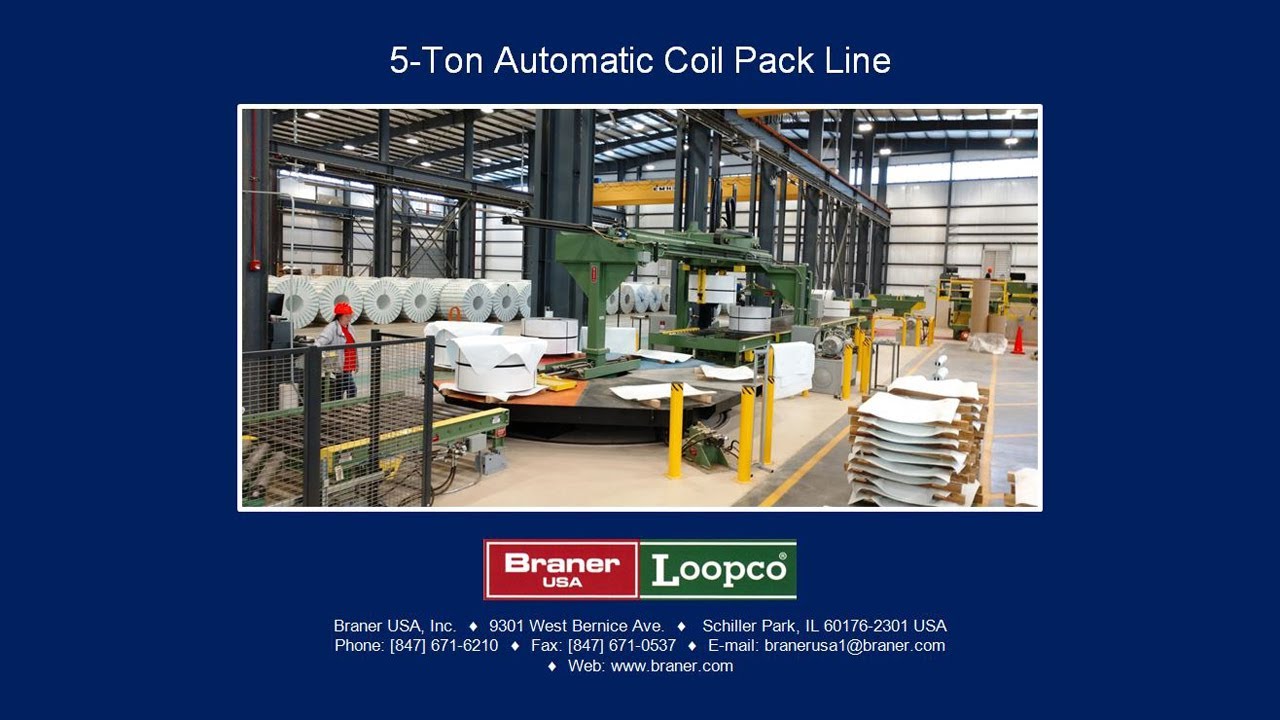

Once the coils are wrapped and protected, they are moved to the final stage of the packaging line, where they are labeled and palletized. This step ensures that the coils are easily identifiable and organized for efficient storage and transportation. The closed type I packaging unit provides a controlled environment for labeling and palletizing, minimizing the risk of errors or damage.

In conclusion, the coil packing line is an integral part of a steel cold rolling project, ensuring the safe and efficient packaging of cold rolled coils. The closed type I packaging unit, connected to two galvanizing units, offers a comprehensive solution for protecting the coils and enhancing their durability. The cold rolled coil packaging work steps encompass various procedures, including inspection, strapping, wrapping, galvanizing, labeling, and palletizing. By adhering to these steps, the steel industry can maintain the quality and integrity of their products, guaranteeing customer satisfaction and facilitating smooth transportation.

coil packing line

"Cold Rolled Coil Packaging: Streamlining Work Steps and Enhancing Efficiency in Coil Packing Line"