The importance of efficient steel sheet cutting in the coil packing line cannot be overstated. With the right amount of steel sheet cut, companies can save on material costs and improve overall productivity. In this article, we will delve into the significance of the steel sheet cutting machine in the coil packing line and how it optimizes the wrapping process.

Steel sheets are widely used in various industries, including automotive, construction, and manufacturing. These sheets are typically produced in coils, which are then cut into smaller pieces for further processing. However, cutting the steel sheets to the precise length required can be a challenging and time-consuming task.

This is where the steel sheet cutting machine for the coil packing line comes into play. Equipped with advanced technology and precision engineering, this machine ensures that the right amount of steel sheet is cut to wrap around the coil. By doing so, it eliminates unnecessary waste and reduces material costs significantly.

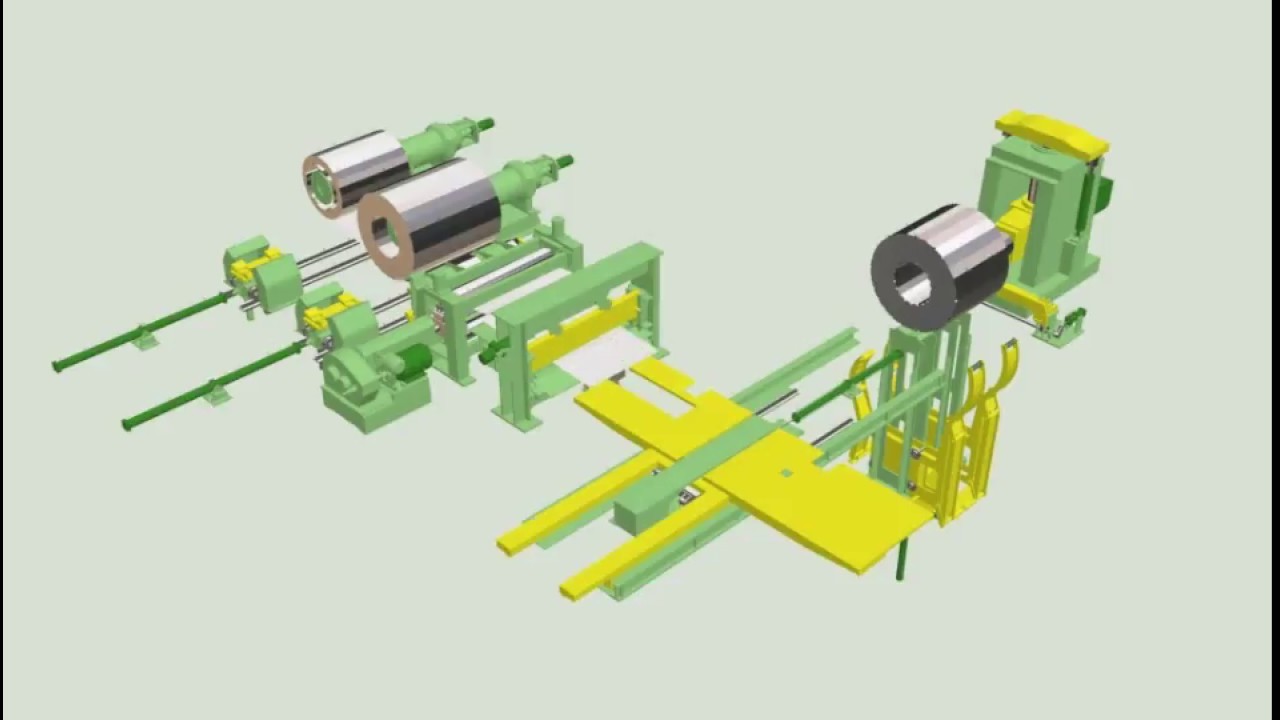

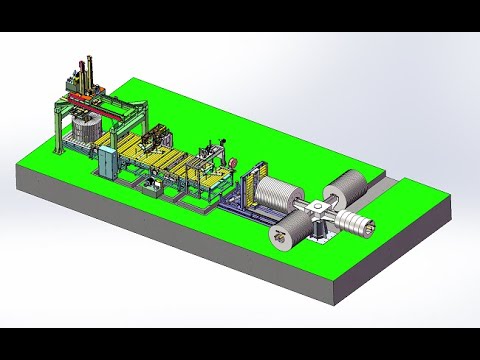

The coil packing line consists of several components, including the steel sheet cutting machine. This machine is responsible for cutting the steel sheets to the desired length before they are wrapped around the coil. It uses various cutting techniques, such as shear cutting or rotary cutting, depending on the specific requirements of the coil packing process.

One of the main advantages of using a steel sheet cutting machine in the coil packing line is its ability to achieve consistent and accurate cuts. This ensures that each piece of steel sheet is precisely sized, eliminating any inconsistencies that may arise from manual cutting. As a result, companies can achieve better quality control and improve the overall efficiency of their operations.

Moreover, the steel sheet cutting machine enhances productivity by reducing downtime and increasing throughput. With its automated cutting process, it can handle a large volume of steel sheets with minimal human intervention. This not only speeds up the coil packing line but also allows operators to focus on other important tasks, improving overall workflow efficiency.

The coil packing line is a critical component of the steel sheet manufacturing process, and any disruptions or inefficiencies can have a significant impact on production. By incorporating a steel sheet cutting machine into the line, companies can ensure a seamless and streamlined operation.

In addition to the immediate benefits of cost savings and improved productivity, the steel sheet cutting machine also offers long-term advantages. For instance, by minimizing material waste, companies can reduce their environmental footprint and contribute to sustainability initiatives. Additionally, the consistent and accurate cuts achieved by the machine result in better product quality, enhancing customer satisfaction and loyalty.

As technology continues to advance, the steel sheet cutting machine for the coil packing line is expected to evolve as well. Manufacturers are constantly innovating and introducing new features to enhance cutting precision, speed, and versatility. This ongoing development ensures that companies can stay ahead of the competition and meet the ever-increasing demands of the market.

In conclusion, the steel sheet cutting machine plays a vital role in the coil packing line, enabling companies to cut the right amount of steel sheet and optimize material usage. With its precise and automated cutting process, it enhances productivity, improves product quality, and reduces costs. As the demand for steel sheets continues to grow, investing in a reliable and efficient steel sheet cutting machine is essential for companies looking to stay competitive in the industry.

coil packing line

“Efficient Steel Sheet Cutting Machine for Coil Packing Line to Enhance Packaging Process”